Abaqus User Subroutines Reference Guide

Abaqus ID:

Printed on:

USER SUBROUTINES REFERENCE GUIDE

ABAQUS 2016

Abaqus User Subroutines

Reference Guide

Abaqus ID:

Printed on:

Legal Notices

Abaqus, the 3DS logo, and SIMULIA are commercial trademarks or registered trademarks of Dassault Systèmes or its subsidiaries in the United States

and/or other countries. Use of any Dassault Systèmes or its subsidiaries trademarks is subject to their express written approval.

Abaqus and this documentation may be used or reproduced only in accordance with the terms of the software license agreement signed by the customer, or,

absent such an agreement, the then current software license agreement to which the documentation relates.

This documentation and the software described in this documentation are subject to change without prior notice.

Dassault Systèmes and its subsidiaries shall not be responsible for the consequences of any errors or omissions that may appear in this documentation.

© Dassault Systèmes, 2015

Other company, product, and service nam es may be trademarks or service marks of their respective owners. For additional information co ncerning

trademarks, copyrights, and licenses, see the Legal N otices in the Abaqus 2016 Installation and Licensing Guide.

Abaqus ID:

Printed on:

Preface

This section lists v a rio us resources that are available fo r help with using Abaqus Unified FEA software.

Support

Both technical softw are support (for problems with creatingamodelorperformingananalysis)andsystems

support (for installatio n, licensing, and hardware-related problems) for Abaqus are offered through a global

network of support offices, as well as through our online support system. Contact information for our

regional offices is accessible from

SIMULIA→Locations at www.3ds.com/simulia. The online support

system is accessible by selecting the

SUBMIT A R EQUEST link at Suppor t - Dassault Systèmes

(http://www.3ds.com /sup port).

Online support

Dassault Systèmes provides a knowledge base of questions and answers, s olutions to questions that we have

answered, and guidelines on how to use Abaqus, Engineering Process Composer, Isight, Tosca, fe-safe, and

other SIMULIA produ cts. The knowledge base is available b y using the

Search our Knowledge option on

www.3ds.com/support (http://www.3ds.com /su ppo rt).

By using the online support system, y ou can also submit new requests for support. All support/service

requests are tracked. I f you contact us by means outside the system to discuss an ex isting support problem

and you know the support request num ber, please mention it so that we can query the sup port system to see

what the latest action has been.

Training

All SIMULIA regional offices offer regularly scheduled public training classes. The courses are offered in

a traditional classroo m form and via the Web. We also provide training s eminars a t customer sites. All

training classes and seminars include workshops to provide as much practical experience with Abaqus as

possible. For a schedule and descriptions of available classes, see the

Training link at www.3ds.com/products-

services/simulia (www.3ds.com/products-services/simulia) or call your support office.

Feedback

We welcome any suggestions for impro vements to Aba qus software, the supp ort tool, or documentatio n.

We will ensure that any enhancement requests you make are considered for future releases. I f you wish to

make a suggestion about the service or products, refer to www.3ds.com/simulia. Comp laints should be mad e

by contacting your suppo rt office or by visiting

SIMULIA→Quality Assurance at w ww.3ds.com/simulia

(www.3ds.com/simulia).

Abaqus ID:

Printed on:

Abaqus ID:

Printed on:

CONTENTS

Contents

1. User Subroutines

Abaqus/Standard subroutines

CREEP: Define time-dependent, viscoplastic behavior (creep and swelling). 1.1.1

DFLOW: Define nonuniform pore fluid velocity in a consolidation a nalysis. 1.1.2

DFLUX: Define nonuniform distributed flux in a heat transfe r or ma ss diffusion analysis. 1.1.3

DISP: Specify prescribed boundary conditions. 1.1.4

DLOAD: Specify nonuniform distributed loads. 1.1.5

FILM: D efine nonuniform film coefficient and associated sink tem peratures for heat

transfer analysis. 1.1.6

FLOW: Define nonuniform seepage coefficient and associated sink pore pressure for

consolidation analysis. 1.1.7

FRIC: Define frictional behavior for contact surfaces. 1.1.8

FRIC_COEF: Define the frictional coefficient for contact surfaces. 1.1.9

GAPCON: Define conductance between contact surfaces or nodes in a fully coupled

temperature-displacement analysis, coupled thermal-electrical-structural analysis,

or pure heat transfer analysis. 1.1.10

GAPELECTR: Define electrical conductance between surfaces in a coupled

thermal-electrical or a coupled thermal-electrical-structural analysis. 1.1.11

HARDINI: Define initial equivalent plastic strain and initial backstress tensor. 1.1.12

HETVAL: Provide internal heat generation in heat transfer analysis. 1.1.13

MPC: Define multi-point constraints. 1.1.14

ORIENT: Provide an orientation for defining local material directions or local directions

for kinem atic coupling constraints or local rigid body directions for ine rtia relief. 1.1.15

RSURFU: Define a rigid surface. 1.1.16

SDVINI: Define initial solution-dependent state variable fields. 1.1.17

SIGINI: Define an initial stress field. 1.1.18

UAMP: Specify amplitudes. 1.1.19

UANISOHYPER_INV: Define anisotropic hyperelastic material behavior using the

invariant form ulation. 1.1.20

UANISOHYPER_STRAIN: Define anisotropic hyperelastic material behavior based on

Green strain. 1.1.21

UCORR: Define cross-correl ation propertie s for random response loading. 1.1.22

UCREEPNETWORK: Define tim e-dependent behavior (creep) for models defined within

the parallel rheological framework. 1.1.23

UDECURRENT: Define nonuniform volume current density in an eddy current or

magnetostatic analysis. 1.1.24

i

Abaqus ID:sub-toc

Printed on: Fri June 19 -- 10:26

:53 2015

CONTENTS

UDEMPOTENTIAL: Define nonuniform magnetic vector potential on a surf ace in an

eddy current or magnetostatic analysis. 1.1.25

UDMGINI: Define the dama ge initiation criterion. 1.1.26

UDSECURRENT: Define nonuniform surface current density in an eddy current or

magnetostatic analysis. 1.1.27

UEL: Define an elem ent. 1.1.28

UELMAT: Define an elem ent with access to materials. 1.1.29

UEXPAN: Define incremental thermal strains. 1.1.30

UEXTERNALDB: Manage user-defined external databases and calculate

model-independent history information. 1.1.31

UFIELD: Specify predefined field variables. 1.1.32

UFLUID: Define fluid density and fluid compl iance for hydrostati c fluid elements . 1.1.33

UFLUIDCONNECTORLOSS: Define the loss coefficient for fluid flow in fluid pipe

connector elements. 1.1.34

UFLUIDCONNECTORVALVE: Define the valve opening to control flow in fluid pipe

connector elements. 1.1.35

UFLUIDLEAKOFF: Define the fluid lea k-off coefficients for pore pressure cohesive

elements. 1.1.36

UFLUIDPIPEFRICTION: Define the frictional coefficient for fluid flow in fluid pipe

elements. 1.1.37

UGENS: Define the mechanical behavior of a shell section. 1.1.38

UHARD: Define the yield surface size and hardening parameters for isotropic plasticity

or combined hardening models. 1.1.39

UHYPEL: Define a hypoelastic stress-strain relation. 1.1.40

UHYPER: Define a hyperelastic material. 1.1.41

UINTER: Define surface interaction behavior for contact surfaces. 1.1.42

UMASFL: Specify prescribed m ass flow rate conditions for a convection/diffusion heat

transfer analysis. 1.1.43

UMAT: Define a material’s m echanical behavior. 1.1.44

UMATHT: Define a material’s thermal behavior. 1.1.45

UMESHMOTION: Specify mesh motion constraints during adaptive meshing. 1.1.46

UMOTION: Specify motions during cavity radiation heat transfer analysis or steady-state

transport analysis. 1.1.47

UMULLINS: Define damage variable for the Mullins effect material model. 1.1.48

UPOREP: Define initial fluid pore pressure . 1.1.49

UPRESS: Specify prescribed equivalent pressure stress conditions. 1.1.50

UPSD: Define the frequency dependence for random response loading. 1.1.51

URDFIL: Read the results file. 1.1.52

USDFLD: Redefine field variables at a material point. 1.1.53

UTEMP: Specify prescribed tem peratures. 1.1.54

UTRACLOAD: Specify nonuniform traction loads. 1.1.55

UTRS: Define a reduced time shift function for a viscoelastic material. 1.1.56

ii

Abaqus ID:sub-toc

Printed on: Fri June 19 -- 10:26

:53 2015

CONTENTS

UTRSNETWORK: Define a reduced time shift function for models defined within the

parallel rheological framework. 1.1.57

UVARM: Generate element output. 1.1.58

UWAVE: Define wave kinematics for an analysis. 1.1.59

UXFEMNONLOCALWEIGHT: Define the weight function used to compute the average

stress/strain to dete rmine the crack propagation direction. 1.1.60

VOIDRI: Define initial void ratios. 1.1.61

Abaqus/Explicit subroutines

VDFLUX: Specify nonuniform distributed fluxes in an explicit dynamic coupled

temperature-displacement analysis. 1.2.1

VDISP: Specify pres cribed boundary conditions. 1.2.2

VDLOAD: Specify nonuniform distributed loads. 1.2.3

VEXTERNALDB: User subroutine that gives control to the user at key moments of the

analysis so that data can be exchanged dynamically among user subroutines and

with external programs or files. 1.2.4

VFABRIC: Define fabric material behavior. 1.2.5

VFRIC: Define frictional behavior for contact surfaces. 1.2.6

VFRIC_COEF: Define the frictional coefficient for contact surfaces. 1.2.7

VFRICTION: Define frictional behavior for contact surfaces. 1.2.8

VUAMP: Specify amplitudes. 1.2.9

VUANISOHYPER_INV: D efine anisotropic hyperelastic m aterial behavior using the

invariant form ulation. 1.2.10

VUANISOHYPER_STRAIN: Define anisotropic hyperelastic material behavior based

on Green strain. 1.2.11

VUCHARLENGTH: Define characteristic elem ent length at a material point. 1.2.12

VUCREEPNETWORK: Define time-dependent behavior (creep) for models defined

within the parallel rheological framework. 1.2.13

VUEL: Define an element. 1.2.14

VUEOS: Define equation of state material model. 1.2.15

VUFIELD: Specify predefined field variables. 1.2.16

VUFLUIDEXCH: Define the mass flow rate/heat energy flow rate for fluid exchange. 1.2.17

VUFLUIDEXCHEFFAREA: Define the effective area for fluid exchange. 1.2.18

VUHARD: Define the yield surface size and hardening parameters for isotropic plasticity

or combined hardening models. 1.2.19

VUINTER: Define the interaction between contact surfaces. 1.2.20

VUINTERACTION: Define the contact interaction between surfaces with the general

contact algorithm. 1.2.21

VUMAT: Define material behav ior. 1.2.22

VUMULLINS: Define damage variable for the Mullins effect material model. 1.2.23

VUSDFLD: Redefine field variables at a m aterial point. 1.2.24

VUTRS: Define a reduced time shift function for a viscoelastic materia l. 1.2.25

iii

Abaqus ID:sub-toc

Printed on: Fri June 19 -- 10:26

:53 2015

CONTENTS

VUVISCOSITY: Define the shear viscosity for equation of sta te models. 1.2.26

VWAVE: Define wave kinematics for an analysis. 1.2.27

Abaqus/CFD subroutines

SMACfdUserPressureBC: Specify prescribed pressure boundary conditions. 1.3.1

SMACfdUserVelocityBC: Specify prescribed velocity boundary conditions. 1.3.2

2. Utility Routines

Obtaining Abaqus environment variables 2.1.1

Obtaining the Abaqus job name 2.1.2

Obtaining the A baqus output directory name 2.1.3

Obtaining parallel processes information 2.1.4

Obtaining part information 2.1.5

Obtaining material point information in an Abaqus /Standard analysis 2.1.6

Obtaining material point information in an Abaqu s/Explicit analysis 2.1.7

Obtaining material point information averaged at a node 2.1.8

Obtaining node point information 2.1.9

Obtaining node to element connectivit y 2.1.10

Obtaining stress invariants, principal stress/strain values and dir ections, and rotating

tensors in an Abaqus/Standard analysis 2. 1.11

Obtaining principal stress/strain values and directions in an Abaqus/Explicit analysis 2.1.12

Obtaining wave kinematic data in an Abaqus/Aqua analysis 2.1.13

Printing messages to the message or status file 2.1.14

Terminating an analysis 2.1.15

Obtaining sensor information 2.1.16

Accessing Abaqus materials 2.1.17

Accessing Abaqus thermal m aterials 2.1.18

Obtaining scalar state information in an Abaqus/CFD analysis 2.1.19

Obtaining vector stat e information in an Abaqus/CFD analysis 2.1.20

Obtaining the MPI communicator in an Abaqus/CFD analysis 2.1.21

Ensuring thread safet y 2.1.22

Allocatable arrays 2.1.23

A. Index

User subroutines index A.1

User subroutine functions listing A.2

iv

Abaqus ID:sub-toc

Printed on: Fri June 19 -- 10:26

:53 2015

1.0 INTRODUCTION

This guide describes all of the user subroutines and utility routines availabl e i n Abaqus. The interface and

requirements for each user subroutine are discussed in detail. References to practical examples of most

subroutines are also provided. Utility routines can be used within user subroutines to p erform a variety of

common tasks. The interface for a ll avai labl e utility routines appears in a separate chapter. For information

on incorporating a user subroutin e into an Abaqu s analysis, see “User subroutines: overview,” Section 18 .1.1

of the Abaqus Analysis User’s Guide.

Most user subroutine interfaces in this guide use the Fortran language, although user subroutines can be

written using the C and C++ languages. Similar ly, the utility r out ines can be invoked from within these C

and C++ user subroutines. For more information, refer to “Writing a user subroutine” in “User subroutines:

overview,” Section 18.1.1 of the Abaqus Analysis User’s Guide, and “Writing user subroutines in C++” in

the Dassault Systèmes Knowledge Base at www.3ds.com/support/knowledge-base.

This guide is divided into four main sections:

•

“Abaqus/Standard subroutines,” Sectio n 1.1 covers all of the user subroutines availab le for use in an

Abaqus/Standard analysis. Each section d iscusses a particular subroutine. The sections are organized

alphabetically according to the subroutine name.

•

“Abaqus/Explicit subrou tin es,” Section 1.2 covers all of the user subroutines available f or use in an

Abaqus/Explicit analysis. Each section discusses a particular subroutine. The sections are organized

alphabetically according to the subroutine name.

•

“Abaqus/CFD subroutines,” Section 1.3 covers all of th e user subroutines available for use in a n

Abaqus/CFD analysis. Each section discusses a particular subroutine. The sections are organized

alphabetically according to the subroutine name.

•

“Utility routines,” Section 2.1 covers all of the utility routines available for use in coding u ser su br outines.

Each section discusses a task that can be performed using a uti lity routine. Al l of the uti lit y routi nes

associated with a particular task appear in the same section.

1.0–1

Abaqus ID:

Printed on:

USER SUBROUTINES

1. User Subroutines

•

“Abaqus/Standard su broutines,” Section 1.1

•

“Abaqus/Explicit subroutines,” Section 1.2

•

“Abaqus/CFD subroutines,” Section 1.3

Abaqus ID:

Printed on:

Abaqus/Standard SUBROUTINES

1.1 Abaqus/Standard subroutines

•

“CREEP,” Section 1 .1.1

•

“DFLOW,” Section 1.1.2

•

“DFLUX,” Section 1.1.3

•

“DISP,” Section 1.1.4

•

“DLOAD,” Section 1.1.5

•

“FILM,” Section 1.1.6

•

“FLOW,” Section 1.1.7

•

“FRIC,” Section 1.1.8

•

“FRIC_COEF,” Section 1.1.9

•

“GAPCON,” Section 1.1.10

•

“GAPELECTR,” Section 1.1.11

•

“HARDINI,” Section 1.1.12

•

“HETVAL,” Section 1.1.13

•

“MPC,” Section 1.1.14

•

“ORIENT,” Section 1.1.15

•

“RSURFU,” Section 1.1.16

•

“SDVINI,” Section 1.1.17

•

“SIGINI,” S ection 1.1.18

•

“UAMP,” Section 1.1.19

•

“UANISOHYPER_INV,” Section 1.1.20

•

“UANISOHYPER_STRAIN,” Section 1.1.21

•

“UCORR,” Section 1.1.22

•

“UCREEPNETWORK,” Section 1.1.23

•

“UDECURRENT,” Section 1.1.24

•

“UDEMPOTEN TIAL,” Section 1.1.25

•

“UDMGINI,” Section 1.1.26

•

“UDSECURRENT,” Section 1.1.27

•

“UEL,” Section 1.1.28

•

“UELMAT,” Section 1.1.29

•

“UEXPA N ,” Section 1.1.30

•

“UEXTERNALDB,” Section 1.1.31

•

“UFIELD,” Section 1.1.32

1.1–1

Abaqus ID:

Printed on:

Abaqus/Standard SUBROUTINES

•

“UFLUID,” Section 1.1.33

•

“UFLUIDCONNECTORLOSS,” Section 1.1.34

•

“UFLUIDCONNECTORVALVE,” Section 1.1.35

•

“UFLUIDLEAKOFF,” Section 1.1.36

•

“UGENS,” Section 1.1.38

•

“UHARD,” Section 1.1.39

•

“UHYPEL,” Section 1 .1.40

•

“UHYPER,” Section 1.1.41

•

“UINTER,” Section 1.1.42

•

“UMASFL,” Section 1.1.43

•

“UMAT,” Section 1.1.44

•

“UMATHT,” Section 1.1.45

•

“UMESHMOTION,” Section 1.1.46

•

“UMOTION,” Section 1.1.47

•

“UMULLINS,” Section 1 .1.48

•

“UPOREP,” Section 1.1.49

•

“UPRESS,” Section 1.1.50

•

“UPSD,” Section 1.1.51

•

“URDFIL,” Section 1.1.52

•

“USDFLD,” Section 1.1.53

•

“UTEMP,” Section 1.1.54

•

“UTRACLOAD,” Section 1.1.55

•

“UTRS,” Section 1.1.56

•

“UTRSNETWORK,” Section 1.1.57

•

“UVARM,” Section 1.1.58

•

“UWAVE,” Section 1.1.59

•

“UXFEMNONLOCALWEIGHT,” Section 1.1.60

•

“VOIDRI,” Section 1.1.61

1.1–2

Abaqus ID:

Printed on:

CREEP

1.1.1 CREEP: User subroutine to define time-dependent, viscoplastic behavior (creep

and swelling).

Product:

Abaqus/Standard

References

•

“Rate-dependent plasticity: creep and swelling,” Section 23.2.4 of the Abaqus Analysis User’s

Guide

•

“Extended Drucker-Prager models,” Section 23.3.1 of the Ab aqus Analysis User ’s G uid e

•

“Modified Drucker-Prager/C ap model,” Section 23.3.2 of the Abaqus Analysis User’s Guide

•

“Defining the gasket behavior d irectly using a gasket behavior model,” Section 32.6.6 of the Abaqus

Analysis User’s Guide

• *

CAP CREEP

• *

CREEP

• *

DRUCKER PRAGER CREEP

• *

SWELLING

•

“Verification o f creep integration,” Section 3.2.6 of the Abaqus Benchmarks G uide

Overview

User subroutine CREEP will be called at all integration po ints o f elements for which t he material

definition contains user-subroutine-defined metal creep, time-dependent volumetric swelling,

Drucker-Prager creep, or cap creep behavior, during procedures that allow viscoplastic response of

the above type t o occur (su ch as the quasi-static procedure). Thi s subroutin e will also be called at all

integration points of gasket elem ents f or which the behavior definition co ntains user-subroutine-defined

creep.

If user subroutine CREEP is used to define a material behavior, the subroutine:

•

is intended to provid e the “uniaxial” creep laws that are to be included in a general tim e-dep e nden t,

viscoplastic material formulation;

•

can be used in the coupled-temperature displacement ( “Fully coupled thermal-stress analysis,”

Section 6.5.3 of the Abaqus Analysis User’s Guide), coupled thermal-electrical-structural (“Fully

coupled thermal-electrical-structural analy sis,” Section 6.7.4 of the Abaqus An alysis User’s

Guide), soils (“Coupled pore fluid diffusion and stress analysis,” Sect ion 6.8.1 of the Abaqus

Analysis User ’s Guide), and quasi-static (“Quasi-static analysis,” Section 6.2.5 of the Abaqus

Analysis User’s Guide) procedures;

•

allows fo r the definition of creep law s for which the meaning and internal use depend on the material

model with which they are being used;

1.1.1–1

Abaqus ID:

Printed on:

CREEP

•

allows creep and swelling to b e combined with rate-independent plastic behavior in a coupled

manner, or they m ay simply be t he only inelastic behaviors of the m a terial, in which case Mises

behavior is assumed;

•

can use and update solution-depen dent state variables; and

•

can be used in conjunctionwithusersubroutineUSDFLD to redefine any field variables before they

are passed in.

If user su bro utine CREEP is u s ed to define rate-dependent behavior in the thickness direction for a gasket,

the subro utine:

•

is intended to provide th e creep laws th at ar e used to prescribe the thickness-direction behavior for

agasket;

•

can be used only in a quasi-static (“Quasi-static analysis,” Section 6.2.5 of the Abaqus Analysis

User’s Guide) procedure;

•

is used in a coupled form with the elastic-plastic m odel used to define the r ate-independent part of

the thickness-direction behavior of the gasket; and

•

can use and update solution-dependent variables.

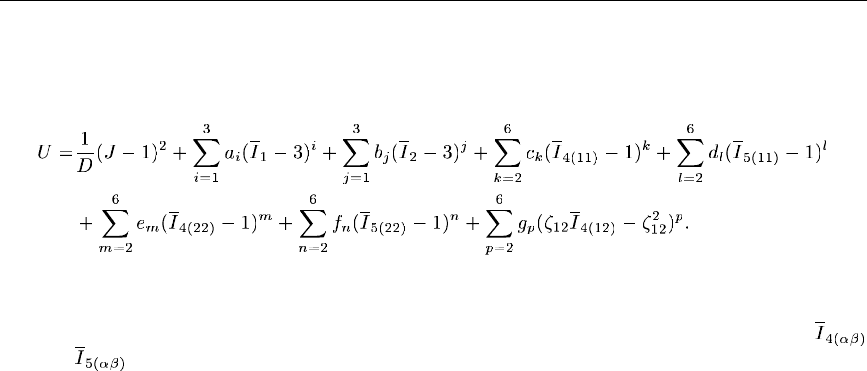

Metals

For metals w ho se material behav ior includes m etal creep and/or tim e -d epend e nt volum e tric swellin g,

the routine allows any “creep” and “swelling” laws ( vi scoplastic behavior) of the follow ing general form

to be defined:

where

is the uniaxial equ ival ent “creep” strain, conjugate to , the Mises or Hill equivalent stress;

is the volum etr ic swellin g strain;

p is the equivalent pressure stress,

;and

is the equivalent deviatoric stress (Mises’ or, if anisotropic creep behavio r is defined, Hill’s

definition).

The user subroutine must defi ne the increment s of inelastic stra in,

and , as functions of

p and

and any other variables used in the definitions of and (such as solution-dependent state

variables introduced by you) and of the time increment,

. If any solution-dependent state variables are

included in the definitions of

and , they must also be integ rated forward in time i n this rou tine.

Abaqus computes the incremental creep strain (or the incremental viscoplastic strain) components

as

1.1.1–2

Abaqus ID:

Printed on:

CREEP

where is the gradient of the deviatoric stress potential, defined as

and is a mat rix with the an isotr opic swelling ratios in the diagonal if an isotrop ic swelling is defined;

otherwise,

.

Drucker-Prager materials

For materials that yield according to the extended Drucker-Prager p lasticity models using Drucker-Prager

creep, the routine allows any “creep” laws (viscoplastic behavior) of the following general form to be

defined:

where

is the equivalent creep stress defined as

if creep is defined in term s of uniaxial compression,

if creep is defined in terms of uniaxial tension , and

if creep is defined in term s of pure shear,

where q is the equivalent deviatoric Mises’ stress, p is the pressure stress, and

is the friction

angle, and

is the uniaxial equivalent “creep” strain, conjugate to such that .

The user subroutine must define the increment of inelastic strain,

, as a f u nction of and

any o ther variables used in the definition s of

(such as solution-dependent state variables introduced

by you) and of the time increment,

. If any solution-dep enden t state variables are i nclu ded in the

definitions of

, they must also be integrated forward in time in this routine.

Abaqus computes the incremental creep strain (or the incremental viscoplastic strain) components

as

where The variable is determ in ed in such a way that

1.1.1–3

Abaqus ID:

Printed on:

CREEP

and

is the hyper bol ic creep potential, where is the dil ation angle measured in the p–q plane at high

confining pressure,

is the in iti al yield stress, an d is the eccentricity. See “Extended

Drucker-Prager models,” Section 23.3.1 of the Abaqus Analysis User’s Guide, for a discussion of

, ,

and

.

Capped Drucker-Prager materials

For materials that yield according to the modified Drucker-Prager/Cap plasticity model using cap creep,

the routine allows any “cohesion creep” and “consolidation creep” laws (viscoplastic behavior) of the

following general form to be defined:

where

is the equivalent creep stress defined from uniaxial compression test d a ta as

where q is the equivalent deviatoric Mises’ stress, p is the pressure stress, and

is the friction angle;

is th e equival ent cohesion creep uniaxial strain, conjugate to such that

,where is defined below;

is the effective creep pressure ( and is the cap

hardening parameter); and

is the volu m et ric consolidatio n creep strain.

Theusersubroutinemustdefine the increments of inelastic strain,

and/or ,as

functions of

and/or and any other variables used in the definitions of and (such

as solution-dependent state variables introduced by y ou) and of the time increment,

.Ifany

solution-dependent state variables are included in th e definitions of

and , they m ust a lso be

integrated forward in tim e in this routi ne.

Calculation of incremental creep strains for the cohesion mechanism

Abaqus computes the i ncrem ental creep strain (or the incremental viscoplastic strain) components of the

cohesion mechanism as

1.1.1–4

Abaqus ID:

Printed on:

CREEP

where d is the material co hesion , the var iable is determined in such a way that

and is the cohesion creep potential

Calculation of incremental creep strains for the consolidation mechanism

Abaqus computes the i ncrem ental creep strain (or the incremental viscoplastic strain) components of the

consolidation mechanism as

where R contro ls the shape of the cap, and is the conso lidation creep potential

Cohesion material properties are determined w ith a uniax ial compression test in which

, and consolidation mater ial properties are determined with a volumetric compression test in which

. Most likely, is a positive function of ,and is a positive function of .

Gaskets

For gaskets whose behavior includes creep, the rou tin e allows any “creep” law of the fo llowing general

form to be defined:

where is the compressive creep strain, conjugate to , the compressive stress in the gasket.

Theusersubroutinemustdefine th e increments of inelastic creep strain,

, as functions of and

any o ther variables used in the definition s of

(such as solution-dependent state variables introduced

by you) and of the time increment,

. If any solution-dep enden t state variables are i nclu ded in the

definitions of

, they must also be integrated forward in time in this routine. Abaqus will automatically

multiply this creep strain by the proper thickness (see “Defining th e gasket behavior directly using a

gasket behavior model,” Section 32.6.6 of the Abaqus Analysis User’s Guide) to obtain a creep closure.

1.1.1–5

Abaqus ID:

Printed on:

CREEP

Integration schemes

Abaqus prov ides both explicit and implici t time integration o f creep and swelling behavior defined in

this routine. The choice of the tim e integration scheme dep ends on the procedure type, the procedure

definition, and whether a geometric linear or nonlinear analysis is requested (see “Rate-dependent

plasticity: creep and swelling,” Section 23.2.4 of the Abaqus Analysis U ser’s Guide).

Implicit integration is generally more effective when the response period is long relative to typical

relaxation times for t he material . Simple high-temperature structural design ap plicatio ns usually do

not need implicit integration, but more complicated problems (such as might arise in manufacturing

processes), creep buckling applications, or nonstructural problems (such as geotechnical applications)

often are integrated more efficiently by the implicit method provided in the p rogram. If implicit

integration is used with this subroutine, nonlinear equations must be solved at each time step and the

variations of

, , ,or with respect to , , , , p, , ,or must be

defined in the subroutine. To obtain good convergence d uring im pl icit integration, it is essential to

define these quantities accurately.

At the start of a new increment the subroutine is called once for each integration point to calculate

the estimated creep strain based on the state at the start of the increment. Subsequently, it is called

twice for each iteration i f explicit integration is used: once to calculate the creep strain increment at the

start of the increment and once to calculate it at the end of the incre m ent. This is needed to test the

validity of the time increment with respect to the user-specified maximum allowable difference in the

creep strain increment. The flag LEND indicates whether the routine is called at t he start or the end of

the increment. T he subroutine must use the corresponding values of time, temperature, field v ariables,

and solution-dep enden t state v ariables in the calculation of the creep strain increment.

For implicit integration Abaqus uses a local iteration procedure to solve the nonlinear constitutiv e

equations, and th e subroutine is called multiple times. The exact number of calls depends on the

convergence rate of the local iteration procedure and, h ence, will vary from point to point. During

these iterations it is possible for the values of the state variables to be far from their final values when

the equations are solved. Therefore, the coding in t he subroutine must adequately protect against

arithmetic f ailures (such as floating poin t overflows) even when variables are passed in w ith physically

unreasonable values. As in expli cit integration, the variable LEND indicates whether the routine is

called at the start or the end of the increm ent.

Constant stress assumption when defining creep and swelling

When the creep and swelling behavior are defined by sim ple formulæ, it is often possible to calculate

the increments of equivalent creep and swelling strain exactly if it is assumed that the stress is constant

during the increm ent. This approach has the advantage that it provides very good accuracy within the

constant stress assumption. I t also avoids the problem that arises for some creep behavior definitions:

that the creep strain rate becomes infinite at zero tim e ( or strain). Otherwise, in such a case y ou must

protect against causing arithm etic fail ur es at the start of the solution.

1.1.1–6

Abaqus ID:

Printed on:

CREEP

Defining both plasticity and creep

If both plasticity and creep are defined for a material, Abaqus will calculate the creep strain before

entering the plasticity routines. The stresses passed into the creep routine may, therefore, exceed the

yield stress.

Interpretation of stress and strain variables

In finite-strain applicat ions strain variables should be interpreted as logarithmic strains and stresses as

“true” stress.

User subroutine interface

SUBROUTINE CREEP(DECRA,DESWA,STATEV,SERD,EC,ESW,P,QTILD,

1 TEMP,DTEMP,PREDEF,DPRED,TIME,DTIME,CMNAME,LEXIMP,LEND,

2 COORDS,NSTATV,NOEL,NPT,LAYER,KSPT,KSTEP,KINC)

C

INCLUDE 'ABA_PARAM.INC'

C

CHARACTER*80 CMNAME

C

DIMENSION DECRA(5),DESWA(5),STATEV(*),PREDEF(*),DPRED(*),

1 TIME(3),EC(2),ESW(2),COORDS(*)

user coding to define DECRA, DESWA

RETURN

END

Variables to be defined

In all cases

DECRA(1)

The definition depends on the usage:

•

Metal creep: , equivalent (uniaxial) deviatoric creep strain increm ent.

•

Drucker-Prager creep: , equivalent (uniaxial) creep strain increment.

•

Capped Drucker-Prager creep: , equivalent ( uniaxial) cohesion creep strain increment.

•

Gasket creep: , uniaxial compressive creep strain increment.

DESWA(1)

The definition depends on the usage:

•

Metal creep: , volumetric swelling strain increment.

1.1.1–7

Abaqus ID:

Printed on:

CREEP

•

Capped Drucker-Prager creep: , equivalent (volumetric) c onsolidation creep strain

increment.

•

Drucker-Prager and gasket creep: = 0.

For implicit creep integration (LEXIMP=1, see below)

DECRA(2)

The definition depends on the usage:

•

Metal creep and Drucker-Prager creep: .

•

Capped Drucker-Prager creep: .

•

Gasket creep: .

DECRA(3)

The definition depends on the usage:

•

Metal creep: .

•

Drucker-Prager creep, gasket creep, and capped Drucker-Prager creep: = 0.

DECRA(4)

The definition depends on the usage:

•

Metal creep: .

•

Drucker-Prager creep, gasket creep, and capped Drucker-Prager creep: = 0.

DECRA(5)

The definition depends on the usage:

•

Metal creep: .

•

Drucker-Prager creep: .

•

Capped Drucker-Prager creep: .

•

Gasket creep: .

DESWA(2)

The definition depends on the usage:

•

Metal creep: .

•

Drucker-Prager creep, gasket creep, and capped Drucker-Prager creep: = 0.

DESWA(3)

The definition depends on the usage:

•

Metal creep: .

•

Capped Drucker-Prager creep: .

•

Drucker-Prager and gasket creep: = 0.

DESWA(4)

The definition depends on the usage:

1.1.1–8

Abaqus ID:

Printed on:

CREEP

•

Metal creep: .

•

Capped Drucker-Prager creep: .

•

Drucker-Prager and gasket creep: = 0.

DESWA(5)

The definition depends on the usage:

•

Metal creep: .

•

Drucker-Prager creep, gasket creep, and capped Drucker-Prager creep: = 0.

Variables that can be updated

STATEV

An array containing the user-defined solution-dep enden t state variables at th is point. This arra y will be

passed in containing the v alues of these variables at th e start of the increment unless they are updated

in user subroutine USDFLD or UEXPAN, in which case the updated values are passed in. If any of the

solution-dependent variables are being used in conjunction with the creep be havior and the routine was

called at the end of the increment (LEND=1,seethedefinition of LEND below), they must be updated in

this sub rou tin e to their values at the end of the increment. Furthermore, if the solution-dependent state

variables are defined as a function of the creep (swelling) strain increment, they must be updated based

on the creep (swelling) strain increment computed as EC(2)-EC(1) (likewise ESW(2)-ESW(1)),

where EC(1), EC(2), ESW(1),andESW(2) are de fin e d below. You de fine the size of this array by

allocating space for it (see “Allocating space” in “User subroutines: overview,” Section 18.1.1 of the

Abaqus Analysis User’s Guide, for m ore information).

SERD

Magnitude of the strain energy rate d ensity,

(required only in -integral calculations). The strain

energy rate density is defined as

Elastic rates are ignored in the calculation of . The contour integral will, therefore, be path

independent only for steady-state creep conditions; that is, when the creep straining dominates

throughout the specimen.

Variables passed in for information

EC(1)

The definition depends on the usage:

•

Metal creep and Drucker-Prager creep: at the start of the increment.

•

Capped Drucker-Prager creep: at the sta rt of the increment.

•

Gasket creep: at the start of the i ncr emen t.

1.1.1–9

Abaqus ID:

Printed on:

CREEP

EC(2)

The definition depends on the usage:

•

Metal creep and Drucker-Prager creep: at the end of the increment.

•

Capped Drucker-Prager creep: at th e end of the increment.

•

Gasket creep: at the end of the increment.

ESW(1)

The definition depends on the usage:

•

Metal creep: at the start of the increment.

•

Capped Drucker-Prager creep: at the sta rt of the increment.

•

Drucker-Prager and gasket creep: = 0.

ESW(2)

The definition depends on the usage:

•

Metal creep: at the end of the increment.

•

Capped Drucker-Prager creep: at th e end of the increment.

•

Drucker-Prager and gasket creep: = 0.

P

The definition depends on the usage:

•

Metal creep and Drucker-Prager creep: , equivalent pressure stress (in

soils analysis this is the equivalent effective pressure stress).

•

Capped Drucker-Prager creep: , effective creep pressure (in soils analysis p is the

effective pressure stress).

•

Gasket creep: = 0.

If LEND=0, the value is p or

at the beginning o f the increment. If LEND=1,thevalueisp or at

the end of the increment.

QTILD

The definition depends on the usage:

•

Metal creep: , Mises or Hill equivalent stress (the Hill formula is used if anisotropic creep

is defined; see “Anisotropic creep” in “Rate-dependent plasticity: creep and swelling,”

Section 23.2.4 of the Abaqus Analysis User’s Guide).

•

Gasket creep: , the uniaxial compressive stress.

•

Drucker-Prager creep: , equivalent creep stress (in soils analysis this is based on effective

stresses).

•

Capped D rucker-Prager creep: , equivalent creep stress (in soils analysis this is based on

effective stresses).

1.1.1–10

Abaqus ID:

Printed on:

CREEP

If LEND=0, the value is or at the beginning of the increment. If LEND=1,thevalueis or

at the end of the increment.

TEMP

Temperature at the end

of the increment.

DTEMP

Increment of temperature during the time increment.

PREDEF

An array containing the values of all of t he user-specified predefined variables at this point at the end

of the increment (initial v alues at the beginning of the analysis and current values during the analysis).

DPRED

An array containing the increments of all of the predefined variables during the time increm ent.

TIME(1)

Value o f step time at the end of th e increment.

TIME(2)

Value of total time at the end of the increment.

TIME(3)

Value of creep time at the end of the increm ent.

DTIME

Time increment.

CMNAME

User-specified material name or gasket behavior name, left justified. Some internal creep models are

given names starting with the “ABQ_” character string. To avoid conflict, you should not use “ABQ_”

as the leading string for CMNAME.

LEXIMP

Explicit/impl icit flag.

If LEXIMP=0, explicit creep integration is being used and only DECRA(1) and DESWA(1) need

be defined; DECRA(I) and DESWA(I), I=2,5, need not be defined.

If LEXIMP=1, implicit c reep integration is b eing used. The derivatives, DECRA(I) and

DESWA(I), I=2,5, should be defined accurately to achieve rapid convergence of the solution.

LEND

Start/end of increment flag.

If LEND=0, the routine is being called at the start of the increment. In this case DECRA(1) and

DESWA(1) must be defined as the equivalent creep and swelling rates calculated at the beginning of

the incremen t, multip lied by the time incr emen t.

1.1.1–11

Abaqus ID:

Printed on:

CREEP

If LEND=1, the routine is being called at the end of the increment. In this case DECRA(1)

and DESWA(1) must be defined as the equivalent creep and swelling rates calculated at the end of

the increment, multiplied by the time increment. If applicable, the solution-de pendent state variables

STATEV must be updated as well.

COORDS(3)

An array containing the current coordinates of this point.

NSTATV

Number of solution-dependent state variables associated with this material or gasket behavior

type (specified when space is allocated for the array; see “Allocating space” in “User subroutines:

overview,” Section 18.1.1 of the Abaqus Analysis User’s Guide).

NOEL

Element number.

NPT

Integration point number.

LAYER

Layer number (for composite shells and layered solids).

KSPT

Section point number within the c urren t layer.

KSTEP

Step number.

KINC

Increment number.

Example: Hyperbolic sine creep law

Suppose that we wish to model a metal u sing the creep behavior

where A , ,andn are constants.

User subroutine CREEP can be coded as follows:

SUBROUTINE CREEP(DECRA,DESWA,STATEV,SERD,EC,ESW,P,QTILD,

1 TEMP,DTEMP,PREDEF,DPRED,TIME,DTIME,CMNAME,LEXIMP,LEND,

2 COORDS,NSTATV,NOEL,NPT,LAYER,KSPT,KSTEP,KINC)

C

INCLUDE 'ABA_PARAM.INC'

C

1.1.1–12

Abaqus ID:

Printed on:

CREEP

CHARACTER*80 CMNAME

C

DIMENSION DECRA(5),DESWA(5),STATEV(*),PREDEF(*),DPRED(*),

1 TIME(3),COORDS(*),EC(2),ESW(2)

C

C DEFINE CONSTANTS

C

A=

SIG0=

AN=

C

T1=EXP(QTILD/SIG0)

T2=EXP(−QTILD/SIG0)

DECRA(1) = A*(.5*(T1−T2))**AN*DTIME

IF(LEXIMP.EQ.1) THEN

DECRA(5) = AN*A*(.5*(T1−T2))**(AN−1.)*DTIME/

1 SIG0*.5*(T1+T2)

END IF

C

RETURN

END

The derivative

has been defined on the assumption that the subroutine will be used with implicit integration.

1.1.1–13

Abaqus ID:

Printed on:

DFLOW

1.1.2 DFLOW: User subroutine to define nonuniform pore fluid velocity in a consolidation

analysis.

Product:

Abaqus/Standard

References

•

“Pore fluid flow,” Section 34.4.7 o f the Abaqus Analysis User’s Guide

• *

DFLOW

• *

DSFLOW

Overview

User su bro utine DFLOW:

•

can be used to define the variation of the seepage magnitude as a function of position, time, pore

pressure, etc. in a soils consolidation analysis;

•

will be called at each flow integration point for each element-based or surface-based nonuniform

flow definition in t he analysis; a n d

•

ignores any amplitude references that may appear with the associated n onu nif or m flow d efinition.

User subroutine interface

SUBROUTINE DFLOW(FLOW,U,KSTEP,KINC,TIME,NOEL,NPT,COORDS,

1 JLTYP,SNAME)

C

INCLUDE 'ABA_PARAM.INC'

C

DIMENSION TIME(2),COORDS(3)

CHARACTER*80 SNAME

user coding to define FLOW

RETURN

END

1.1.2–1

Abaqus ID:

Printed on:

DFLOW

Variable to be defined

FLOW

Effective velocity of pore fluid crossing the surface at thi s p oin t from the inside of the region modeled

to the outside of the region modeled. Units are LT

−1

. Effective velocity is the volumetric flow rate per

unit area (refer to “Permeability,” Section 26.6.2 of the Abaqus An alysis User’s Guide).

FLOW will be passed into the routine as the magn itu de of the seepage s pecified as part of the

element-based or surface-based flow definition. If the magnitud e is not defined, FLOW will be passed

in as zero.

The effective velocity is not available for output purposes.

Variables passed in for information

U

Estimated pore pressure at this time at this point.

KSTEP

Step number.

KINC

Increment number.

TIME(1)

Current value of step time (defined only in transient analysis).

TIME(2)

Current value of total time (defined only in transient analysis).

NOEL

Element number.

NPT

Integration point number on the element’s surface.

COORDS

An array containing the coordinates of this p oint. These are the current coordinates if geometric

nonlinearity is accounted for du ring the step (see “Defining an analysis,” Section 6.1.2 of the Abaqus

Analysis User’s Guide); otherwise, the array contains the origin a l coordinates of the point.

JLTYP

Identifies the element face for which this call to DFLOW is b e ing made through the element-based flow

definition. Th is information is u seful when several different nonuniform distributed flows are being

imposed on an element at the same time. See Part VI, “Elements,” o f the Abaqus Analysis User’s

Guide for identification of element faces. The key is as follows:

1.1.2–2

Abaqus ID:

Printed on:

DFLOW

JLTYP Flow type

0 Surface-based load

11 S1NU

12 S2NU

13 S3NU

14 S4NU

15 S5NU

16 S6NU

SNAME

Surface name for which this call t o DFLOW is being made through the surface-based flow definition

(JLTYP=0). For an element-based flow d e fin ition the surface name is passed in as a blank.

1.1.2–3

Abaqus ID:

Printed on:

DFLUX

1.1.3 DFLUX: User subroutine to define nonuniform distributed flux in a heat transfer or

mass diffusion analysis.

Product:

Abaqus/Standard

References

•

“Thermal loads,” Section 34.4.4 of the A baqus Analysis User’s Guide

•

“Mass diffusion analysis,” Section 6.9.1 of the Abaqus Analysis User’s Guide

• *

DFLUX

• *

DSFLUX

•

“DFLUX,” Section 4.1.1 of the Abaqus Verification Guide

Overview

User su bro utine DFLUX:

•

can be used to define a nonuniform distributed flux as a function of position, time, tem peratu re,

element n um ber, integration point number, etc. in a heat transfer or mass diffusion analysis;

•

will be called at each flux integration point for each element-based or surface-based ( heat transfer

only) nonunifo rm distributed flux definition in the analysis;

•

ignores any amplitude references that m ay appear with the associated nonuniform distributed flux

definition; and

•

uses the nodes as flux integration points for first-order heat transfer, first-order coupled temperature-

displacement, first-order coupled thermal-electrical-structural, and mass diffusion elements.

User subroutine interface

SUBROUTINE DFLUX(FLUX,SOL,KSTEP,KINC,TIME,NOEL,NPT,COORDS,

1 JLTYP,TEMP,PRESS,SNAME)

C

INCLUDE 'ABA_PARAM.INC'

C

DIMENSION FLUX(2), TIME(2), COORDS(3)

CHARACTER*80 SNAME

user coding to define FLUX(1) and FLUX(2)

RETURN

END

1.1.3–1

Abaqus ID:

Printed on:

DFLUX

Variables to be defined

FLUX(1)

Magnitude of flux flowing into the model at this point. In heat transfer cases the units are J T

−1

L

−2

for

surface fluxes and JT

−1

L

−3

for body flux. In transient heat transfer cases where a non-default amplitude

is used to vary the applied fluxes, the tim e average flux over the time increm ent must be defined rather

than the value at th e e nd of the time increment. In mass diffusion cases the u nits are PLT

−1

for surface

fluxes and PT

−1

for body flux.

FLUX(1) will be passed into the routine as the magnitude of the flux specified as part of the

element-based or surface-based fl ux definition. If the magnitude is not defined, FLUX(1) will be

passedinaszero.

This flux is not available for outpu t purposes.

FLUX(2)

In heat transfer cases:

, the rate of change of the flux with respect to the temperatur e at this point.

The units are JT

−1

L

−2 −1

for surface fluxes and JT

−1

L

−3 −1

for body flux.

In mass diffusion cases:

, the rate of change of the flux with respect to the mass concentration

at this point. The units are LT

−1

for surface fluxes and T

−1

for body flux.

The c onv ergence r ate during the solution of the non lin ear equations in an increment is improved

by defining this value, especially when the flux is a s tron g function of temperature in heat transfer

analysis or concentration in mass diffusion analysis.

Variables passed in for information

SOL

Estimated value of the solution variable (temperature in a heat transfer analysis or concentration in a

mass diffusion analysis) at this time at this poin t.

KSTEP

Step number.

KINC

Increment number.

TIME(1)

Current value of step time (defined only in transient analysis).

TIME(2)

Current value of total time (defined only in transient analysis).

NOEL

Element number.

1.1.3–2

Abaqus ID:

Printed on:

DFLUX

NPT

Integration point number in the element or on the elem ent’s surface. The integration scheme depends

on whether this is a su rface or a body flux.

COORDS

An array containing the coordinates of this p oint. These are the current coordinates if geometric

nonlinearity is accounted for du ring the step (see “Defining an analysis,” Section 6.1.2 of the Abaqus

Analysis User’s Guide); otherwise, the array contains the origin a l coordinates of the point.

JLTYP

Identifies the flux type for which this call to DFLUX is being made. Th e flux type may be a body flux,

a surface-based flux, or an element-based surface flux. F or element-based surface fluxes, this variable

identifies the element face for which this call to DFLUX is being made. This information i s useful when

several different nonunifo rm distributed fluxes are being imposed on an element at the same time. See

Part VI, “Elements,” of the Abaqus A naly sis User’s Guide for element face identification. The key is

as follows:

JLTYP Flux type

0 Surface-based flux

1 BFNU

11 S1NU (SNEGNU for heat transfer shells)

12 S2N U (SPOSNU for heat transfer shells)

13 S3NU

14 S4NU

15 S5NU

16 S6NU

TEMP

Current value of temperature at this integration point (defined only for a m ass diffusion analysis).

Temperature for a heat transfer analysis is passed in as variable SOL.

PRESS

Current value of the eq uiv alent pressure stress at t his integration poi nt (defined only for a mass diffusion

analysis).

SNAME

Surface name for a surface-based flux definition (JLTYP=0). Fo r a bod y flux or an element-based

surface flux the surface name is passed in as blank.

1.1.3–3

Abaqus ID:

Printed on:

DISP

1.1.4 DISP: User subroutine to specify prescribed boundary conditions.

Product:

Abaqus/Standard

References

•

“Boundary c ond itions in Abaqus/Standard and Abaqus/Explicit,” Section 34.3.1 of the Abaq us

Analysis User’s Guide

•

“Connector actuation,” Section 31.1.3 of the Abaqus Analysis User’s Guide

• *

BOUNDARY

• *

CONNECTOR MOTIO N

•

“Riser dynamics,” Section 12.1.2 of the Abaqus Example Problems Guide

•

“DISP,” Section 4.1.2 of the Abaqus Verification Guide

•

“Boundary conditions,” Section 5.1 .5 of the Abaqus Verification Guide

Overview

User subroutine DISP:

•

can be used to defin e the mag nitudes of prescribed boundary con dition s or connector motions;

•

requires incremental values to be defined for prescribed rotation boundary conditions;

•

is called for all degrees of freedom listed in a user-subroutine-defined boundary condition or

connector motion definition;

•

redefines an y magnitudes that may be specified (and possibly modified by an amplitude) as part of

the associated boundary condition or connector motio n definition; and

•

ignores the specified type, if any, of the associated boundary condition or connector motion

definition.

User subroutine interface

SUBROUTINE DISP(U,KSTEP,KINC,TIME,NODE,NOEL,JDOF,COORDS)

C

INCLUDE 'ABA_PARAM.INC'

C

DIMENSION U(3),TIME(3),COORDS(3)

C

user coding to define U

1.1.4–1

Abaqus ID:

Printed on:

DISP

RETURN

END

Variable to be defined

U(1)

All variable types except rotation: the total value of the prescribed variable at this point. T he variable

may be displacement, pore pressure, temperature, etc., depending on the degree of freedom constrained.

U(1) will b e passed into the user su bro utine as the value defined by any magnitude and/or amplitude

specification for the boundary condition or connector motion.

Rotation variable type: the incremental value of the prescribed rotation at this point. The

time increm ent, passed into the user subroutine t hro ugh TIME(3), should be used to calcu late the

incremental value. In addition, U(1) will be passed i nto user subrou tine DISP as the value defined

by any magnitude or amplitude specification for the boundary condition.

If the analysis procedure r equ ires that the time derivatives of prescribed variables be d efined (for

example, in a dynamic analysis the velocity and acceleration, as w ell as the value of the variable,

are needed),

must be given in U(2) and in U(3). The total value of the variable

(incremental value in the case of rotation) and its time derivatives must be given i n user sub routine

DISP, r egard less of the type of boundary condition or connector motion.

Variables passed in for information

KSTEP

Step number.

KINC

Increment number.

TIME(1)

Current value of step time.

TIME(2)

Current value of total time.

TIME(3)

Current value of time increment.

NODE

Node number. This variable cannot be used if user subroutine DISP is used to prescribe connector

motions.

NOEL

Element number. This variable cannot be used if user subroutine DISP is used to prescribe boundary

conditions.

1.1.4–2

Abaqus ID:

Printed on:

DISP

JDOF

Degree of freedom.

COORDS

An array containing the current coordinates of this point. T hese are th e coordinates at the end of the

prior increm ent if geometric nonlinearity is accounted for during the step (see “Defining an analysis,”

Section 6.1.2 of the A baqu s Analy sis User’s Guide); otherwise, the array contains the orig inal

coordinates of the node. This array cannot be used if user subroutine DISP is used to prescribe

connector motions.

1.1.4–3

Abaqus ID:

Printed on:

DLOAD

1.1.5 DLOAD: User subroutine to specify nonuniform distributed loads.

Product:

Abaqus/Standard

References

•

“Distributed loads,” Section 34.4.3 of the Abaqus Analysis User’s Guide

• *

DLOAD

• *

DSLOAD

•

“Nonuniform crack-face loading and J -integrals,” Section 1.16.7 of the Abaqus Benchmarks G uide

•

“Pure bending of a cylinder: CAXA elements,” Section 1.3.33 of the Abaqus Verification Guide

•

“Cylinder subjected to asymmetric pressure loads: CAXA elements,” Section 1.3.35 of the Abaqus

Ver ification Guide

•

“Patch test for axisymmetric elements,” Section 1.5.4 of the Abaqus Verification Guide

•

“Transient int ern al pressure loading of a viscoelastic cylinder,” S ection 2.2.9 of t he Abaqus

Ver ification Guide

•

“DLOAD,” Section 4.1.3 of the Abaqus Verification Guide

Overview

User su bro utine DLOAD:

•

can be used to define the variation of the distributed load magnitude as a function of position, time,

element number, load integration point number, etc.;

•

will be called at each load integration point for each element-based or surface-based nonuniform

distributed load definition d uring stress analysis;

•

will be called at each stiffness integration point for computing the effective axial force, ESF1, for

pipe elements subjected to nonun iform load types PENU and PINU;

•

cannot be used in mode-based procedures to describe the time variation of the load; and

•

ignores any amplitude references that may a ppear with the associated step definition or nonuniform

distributed load defi nition.

User subroutine interface

SUBROUTINE DLOAD(F,KSTEP,KINC,TIME,NOEL,NPT,LAYER,KSPT,

1 COORDS,JLTYP,SNAME)

C

INCLUDE 'ABA_PARAM.INC'

C

DIMENSION TIME(2), COORDS (3)

1.1.5–1

Abaqus ID:

Printed on:

DLOAD

CHARACTER*80 SNAME

user coding to define F

RETURN

END

Variable to be defined

F

Magnitude of the d istr ibu ted load. Units are FL

−2

for surface loads and FL

−3

for body forces. F will be

passed i nto the routin e as the magnitude of the load specified as part of the element-based or surface-

based distributed load definition. If the magnitude is not defined, F will be passed in as zero. For a

static analysis that uses the modified Riks method (“Static stress analysis,” Section 6.2.2 of the Abaqus

Analysis User’s Guide) F must be defined as a function of the load p roportionality factor,

.The

distributed load magnitud e is not available for output pu rp oses.

Variables passed in for information

KSTEP

Step number.

KINC

Increment number.

TIME(1)

Current value of step time or current value of the load proportionality factor,

,inaRiksstep.

TIME(2)

Current value of total time.

NOEL

Element number.

NPT

Load integration point number within the elem ent or on the element’s surface, depending on the

load type. (Stiffness integration point number w h ile computing effective axial force, ESF1, for pipe

elements subjected to load types PENU and PINU.)

LAYER

Layer number (for body fo rces in layered solids).

KSPT

Section point number within the c urren t layer.

1.1.5–2

Abaqus ID:

Printed on:

DLOAD

COORDS

An ar ray containing the coor din a tes of the load integration point. T hese are the current coordinat es if

geometric nonlinearity is accounted for during the step (see “Defining an analysis,” Section 6.1.2 of the

Abaqus Analysis User’s Guide); otherwise, the array contains the original coordinates of the point. For

axisymmetric elements that allow nonaxisymmetric deformation, COORDS(3) is the angular position

of the integration point, in degrees.

JLTYP

Identifies the load type for which this call to DLOAD is being made. The load type m ay be a body force,

a surface-based load, or an element-based surface lo ad. For element-based surface loads, this variable

identifies the element face for which this call to DLOAD is being made. This information i s useful when

several different nonuniform distributed loads are being imposed on an element at the same time. See

Part VI, “Elements,” of the Abaqus A naly sis User’s Guide for element face identification. The key is

as follows:

JLTYP Load type

0 Surface-based load

1 BXNU

1 BRNU

2 BYNU (except for axisymmetric elements)

2 BZNU (for axisymmetric elements only)

3 BZNU (for three-dimensio nal elemen ts and asym metric-axisy mmetric

elements)

20 PNU

21 P1NU

22 P2NU

23 P3NU

24 P4NU

25 P5NU

26 P6NU

27 PINU

28 PENU

41 PXNU

42 PYNU

43 PZNU

1.1.5–3

Abaqus ID:

Printed on:

DLOAD

SNAME

Surface name for a surface-based load definition (JLTYP=0). For a body force o r an element-based

surface load the surface name is passed in as blank.

1.1.5–4

Abaqus ID:

Printed on:

FILM

1.1.6 FILM: User subroutine to define nonuniform film coefficient and associated sink

temperatures for heat transfer analysis.

Product:

Abaqus/Standard

References

•

“Thermal loads,” Section 34.4.4 of the A baqus Analysis User’s Guide

• *

CFILM

• *

FILM

• *

SFILM

•

“Temperature-dependent film condition,” Section 1.3.42 of the Abaqus Verification Guide

Overview

User subroutine FILM:

•

can be used to define a node-based, element-based, or surface-based nonuniform film coefficient;

•

can be used to define sink temperatures as functions of position, time, temperature, node n um ber,

element number, integration point n um ber, etc.;

•

will be called during proced ures that allow heat transfer analysis at each node or surface integration

point of those surfaces and elem ents for which node-based, element-based, or surface-based

nonuniform film conditions are d efined;

•

ignores any amplitude references for the sink temperature or film coefficient that may appear with

the associated nonuniform film definition; and

•

uses the nodes for first-order heat transfer elements as surface integration points for both element-

based and surface-based films.

User subroutine interface

SUBROUTINE FILM(H,SINK,TEMP,KSTEP,KINC,TIME,NOEL,NPT,

1 COORDS,JLTYP,FIELD,NFIELD,SNAME,NODE,AREA)

C

INCLUDE 'ABA_PARAM.INC'

C

DIMENSION H(2),TIME(2),COORDS(3), FIELD(NFIELD)

CHARACTER*80 SNAME

user coding to define H(1), H(2),and SINK

RETURN

END

1.1.6–1

Abaqus ID:

Printed on:

FILM

Variables to be defined

H(1)

Film coefficient at this point. Units are JT

−1

L

−2 −1

. H(1) will be p a ssed into the routine as the

magnitude of the film coefficient specified as part of the node-based, element-based, or surface-based

film conditio n definition. If the m agnitud e is not defined, H(1) will be initi alized to zero.

H(2)

,rateofchangeofthefilm coefficient with respect to the surface temperature at this point. Units

are J T

−1

L

−2 −2

. The rate of convergence during the solut ion of the nonlinear equations in an increment

is improved by defining this value, especially when the film coefficient is a strong function of surface

temperature.

SINK

Sink temperature. SINK will be passed into the routine as the sink temperature s p ecified as part of the

node-based, element-based, or surface-based film con dition definition. If the sink temperature is not

defined, SINK w ill be initialized t o zero.

Variables passed in for information

TEMP

Estimated surface temp erature at this tim e at this point.

KSTEP

Step number.

KINC

Increment number.

TIME(1)

Current value of step time.

TIME(2)

Current value of total time.

NOEL

Element number. This variable is passed in as zero for node-based films.

NPT

Surface integration point number. This variable is passed in as zero for node-based films.

COORDS

An array containing the coordinates of this p oint. These are the current coordinates if geometric

nonlinearity is accounted for du ring the step (see “Defining an analysis,” Section 6.1.2 of the Abaqus

Analysis User’s Guide); otherwise, the array contains the origin a l coordinates of the point.

1.1.6–2

Abaqus ID:

Printed on:

FILM

JLTYP

Identifies the element face for which this call to FILM is being made for an element-based film

coefficient specification. This information is useful when several different n onuniform film conditions

are being imposed on an elem ent at the same time. See P art VI, “Elements,” of the Abaqus A nalysis

User’s Guide for element face identification. The key is as follows:

JLTYP Film type

0 Node-based or surface-based loading

11 F1NU (FNEGNU for heat transfer shells)

12 F2N U (FPOSNU for heat transfer shells)

13 F3NU

14 F4NU

15 F5NU

16 F6NU

FIELD

Interpolated values of field variables at this point.

NFIELD

Number of field variables.

SNAME

Surface name for which this call to FILM is being made for a surface-based film coefficient specification

(JLTYP=0). This variable is passed i n as blank for both node-based and element-based films.

NODE

Node number. This v ariable is passed in as zero for both element-based and surface-based film s.

AREA

Nodal area for n ode-based films. AREA will be passed into the routine as the nodal area specified as part

of the node-based film coefficient specification. This nodal area is not available for output purposes.

This variable is passed in as zero for both element-based and surface-based films.

1.1.6–3

Abaqus ID:

Printed on:

FLOW

1.1.7 FLOW: User subroutine to define nonuniform seepage coefficient and associated

sink pore pressure for consolidation analysis.

Product:

Abaqus/Standard

References

•

“Pore fluid flow,” Section 34.4.7 o f the Abaqus Analysis User’s Guide

• *

FLOW

• *

SFLOW

Overview

User subroutine FLOW:

•

can be used in a soils consolidation an a lysis to define the variation of the r eference pore p ressure and

the seepage coefficient as functions of position, time, pore pressure, e lemen t number, integration

point number, etc.;

•

will be called at each integration point of elem ent surfaces for which element-based or surface-based

nonuniform surface seepage flow is defined; and

•

ignores any amplitude references that may appear with the associated n onu nif or m flow d efinition.

User subroutine interface

SUBROUTINE FLOW(H,SINK,U,KSTEP,KINC,TIME,NOEL,NPT,COORDS,

1 JLTYP,SNAME)

C

INCLUDE 'ABA_PARAM.INC'

C

DIMENSION TIME(2), COORDS(3)

CHARACTER*80 SNAME

user coding to define H and SINK

RETURN

END

1.1.7–1

Abaqus ID:

Printed on:

FLOW

Variables to be defined

H

Seepage coefficient at this point. Units are F

−1

L

3

T

−1

. H will be passed into the routine as the reference

seepage coefficient value specified as part of the element-based or surface-based flow definition. If the

reference valu e is not defined, H will be passed in as zero.

SINK

Sink po re pressure. SINK will be passed into the routine as the reference pore pressure value specified

as part of the element-b ased or surface-based flow definition. If the reference value is not d efined,

SINK will be passed in as zero.

Variables passed in for information

U

Estimated surface total pore pressure at this time and at this point.

KSTEP

Step number.

KINC

Increment number.

TIME(1)

Current value of step time (defined only in transient analysis).

TIME(2)

Current value of total time (defined only in transient analysis).

NOEL

Element number.

NPT

Surface integration point num ber.

COORDS

An array containing the coordinates of this integr atio n point. These are the current coordinates if

geometric nonlinearity is accounted for during the step (see “Defining an analysis,” Section 6.1.2 of

the Abaqus Analysis User’s Guide); otherwise, the array contains the original coordinates of the point.

JLTYP

Identifies the element face for which this call to FLOW is being made for an element-based flow. This

information is useful when several nonuniform flow conditions are being im posed on an element at

the same time. See Part VI, “Elements,” of the Abaqus Analysis User’s Guide f or identification of th e

element faces. The key is as follows:

1.1.7–2

Abaqus ID:

Printed on:

FLOW

JLTYP Flow type

0 Surface-based flow

61 Q1NU

62 Q2NU

63 Q3NU

64 Q4NU

65 Q5NU

66 Q6NU

SNAME

Surface name for which this call to FLOW is being m ade for a surface-based fl ow (JLTYP=0). For an

element-based flow the surface name is passed in as a blank.

1.1.7–3

Abaqus ID:

Printed on:

FRIC

1.1.8 FRIC: User subroutine to define frictional behavior for contact surfaces.

Product:

Abaqus/Standard

References

•

“Frictional behavior,” Section 37.1.5 of the Abaqus Analysis User ’s Guide

• *

FRICTION

•

“Thermal-stress analysis of a disc brake,” Section 5.1.1 of the Abaqus Ex a mp le Problems Guide

•

“FRIC,” Section 4.1.4 of the Abaqus Verification Guide

Overview

User subroutine FRIC:

•

can be used to define the frictional behavior between contacting surfaces;

•

can be used w hen the extended versions of the classical Coulomb friction model provided in A baq us

are too restrictive and a more complex definition of shear transmission between contacting surfaces

is required;

•

will be called at points on the slave surface of a contact pair and at the integration points in a contact

element (only w hen the contact point is closed) for which the contact interaction property m odel

contains user-subroutine-defined friction;

•

must provide the entire definition of shear interaction between the contacting surfaces; and

•

can use and u pdate solution-dependent state variables.

User subroutine interface

SUBROUTINE FRIC(LM,TAU,DDTDDG,DDTDDP,DSLIP,SED,SFD,

1 DDTDDT,PNEWDT,STATEV,DGAM,TAULM,PRESS,DPRESS,DDPDDH,SLIP,

2 KSTEP,KINC,TIME,DTIME,NOEL,CINAME,SLNAME,MSNAME,NPT,NODE,

3 NPATCH,COORDS,RCOORD,DROT,TEMP,PREDEF,NFDIR,MCRD,NPRED,

4 NSTATV,CHRLNGTH,PROPS,NPROPS)

C

INCLUDE 'ABA_PARAM.INC'

C

CHARACTER*80 CINAME,SLNAME,MSNAME

C

DIMENSION TAU(NFDIR),DDTDDG(NFDIR,NFDIR),DDTDDP(NFDIR),

1 DSLIP(NFDIR),DDTDDT(NFDIR,2),STATEV(*),DGAM(NFDIR),

2 TAULM(NFDIR),SLIP(NFDIR),TIME(2),COORDS(MCRD),

1.1.8–1

Abaqus ID:

Printed on:

FRIC

3 RCOORD(MCRD),DROT(2,2),TEMP(2),PREDEF(2,*),PROPS(NPROPS)

user coding to define LM, TAU, DDTDDG, DDTDDP,

and, optio nally, DSLIP, SED, SFD, DDTDDT, PNEWDT, STATEV

RETURN

END

Variables to be defined

In all cases

LM

Relative motion flag. User subroutine FRIC is called only if the contact point is determined to be

closed; that is, if the contact pressure is positive (the contact point was closed in the previous iteration)

or if the con tact point is overclosed (the contact po int was open in the previous iteration).

During iteratio ns LM is passed into the subro utine as the value defined during the previous iteration.

At the start of an increment or if the contact point opened during the previous iteration, this variable

will be passed into the r out ine depending on the contact condition in th e previous incremen t. If the

contact point was slipping, LM is equal to 0; if the contact point was sticking, LM is equal to 1; and if

the contact point was open, LM is equal to 2.

Set LM equal to 0 i f relative mo tion is allowed (either due to slip or elastic stick). In thi s case the

subroutine must specify the f riction a l stress

(and for three-dimensio nal analysis) as a function

of the relative sliding mo tion

(and ), the interface contact pressure p, and other predefined or

user-defined state variables. In addition, the subroutine m ust define the derivatives of the frictional

stress with respect to

,( ), and p. For instance, in the case of isotropic elastic sticking,

, ,where is the elastic stiffness of the interface.

Set LM equal to 1 if no relati ve mot ion is allowed; a rigid sticking cond iti on at the interface is

enforced by a Lagrange multiplier method. In this case no further variables need to be updated. If LM

is always set to 1, a “perfectly rough” interface is created. It is not advisable to set LM to 1 when the

finite-sliding, surface-to-surface contact formulation is used.

Set LM equal to 2 if friction is i gno red (frictionless sliding is assumed). In this case no further

variables need to be u pdated. If LM is always set to 2, a “perfectly smooth” interface is created.

You can ma ke decisions about the stick/slip condition based on incremental slip information and

calculated frictional stresses. These quantities are passed in by Abaqus/Standard, as discussed below.

To avoid convergence problem s for the general class of frictional contact problems, set LM to

2 and exit this routin e if the contact point was open at the end of the previous increment; that is, if

Abaqus/Standard sets LM=2 when it calls this routine, simply exit the routine.

1.1.8–2

Abaqus ID:

Printed on:

FRIC

If the return value of LM is 0

TAU(NFDIR)

These values are passed in as the values o f the frictional stress components,

, at the beginning of

the increment and m ust be updated to the values at the end of the increment. Here, and in the rest of

this description, Greek subscripts (

, ) refer to frictional shear directions. The orientation of t hese

directions on contact surfaces is defined in “Contact formulations in Abaqus/Standard,” Section 38.1.1

of the Abaqus Analysis User’s Guide.

DDTDDG(NFDIR,NFDIR)

/ , p arti al derivative of the frictional stress in direction with r espect to the relative motion

in direction

.

DDTDDP(NFDIR)

/ , partial derivative of the frictional stress in direction with respect to the contact pressure.

Since these terms yield an unsymmetric contribution to the stiffness m atrix, they are used only if the

unsymmetric equation solver is used (see “Defining an analysis,” Section 6.1.2 of the Abaqus A nalysis

User’s Guide).

Variables that can be updated

DSLIP(NFDIR)

, increment in nonrecoverable sliding motion (slip). If LM was 0 in the previous iteration, this

array is passed in as the user-defined values during the previou s iteration ; otherwise, it will be zero.

The array should be updated only if the return value of LM is 0.

This array is useful to detect slip reversals between iterations. It is used by the output op tio ns to

indicate wheth er t his point is sticking or slipping. Upon convergence of an increm ent, the values in

DSLIP(NFDIR) are accumulated in SLIP(NFDIR), which are stored as the plastic strains.

SED

This variable is passed in as the value of the elastic energy density at the start of the increment and

should be updated to t he elastic energy density at the end of the increme nt. T h is variable is used for

output only and h as no effect on other solution v ariab les.

SFD

This variable should be defined as the increm ental frictional di ssipati on. The un its are energy per unit

area if the contact element or contact pair calling FRIC uses stresses as o pposed to forces. For regular

stress analysis this variable is used for output only and has no effect on other solu tio n variables. In

coupled temperature-displacement and coupled thermal-electrical-structural analyses the dissipation is

converted into heat if the gap heat generation model is used. If SFD is not defined, the heat g eneration

is calculated based on the dissipation obtained as the product of the slip increment, DSLIP,andthe

frictional stress, TAU.

1.1.8–3

Abaqus ID:

Printed on:

FRIC

DDTDDT(NFDIR,2)

/ , / partial deriv atives of the frictio nal s tr ess i n direction with respect to the