PNNL-11441

UC-701

ELECTRICALLY SWITCHED

CESIUM ION EXCHANGE

FY 1996 Annual Report

Michael A. Lilga

Rick J. Orth

Johanes P. H. Sukamto

Daniel T. Schwartz

Scott M. Haight

University of Washington

David Genders

Electrosynthesis Company, Inc.

December 1996

Prepared for

the Office of Science and Technology

U.S.

Department of Energy's Office of Environmental Management

Efficient Separations and Processing Crosscutting Program

under Contract DE-AC06-76RLO 1830

Pacific Northwest National Laboratory

Richland, Washington 99352

Summary

An electrochemical method for metal ion separations, called Electrically Switched Ion Exchange

(ESIX), is described in this report. In this method, direct oxidation and reduction of an electroactive

film attached to an electrode surface is used to load and unload the film with alkali metal cations.

The electroactive films under investigation are nickel hexacyanoferrates, which are deposited on the

surface by applying an anodic potential to a nickel electrode in a solution containing the ferricyanide

anion. Reported film preparation procedures have been modified to produce films with improved

capacity and stability. Electrochemical behavior of the derivatized electrodes has been investigated

with use of cyclic voltammetry and chronocoulometry. The films show selectivity for cesium in

concentrated sodium solutions. Raman spectroscopy has been used to directly monitor changes in

oxidation state of the film and imaging experiments have demonstrated that the redox reactions are

spatially homogeneous across the film. Requirements for a bench scale unit have been identified.

m

DISCLAIMER

Portions of this document may be illegible

in electronic image products. Images are

produced from the best available original

document*

Acknowledgments

This work was funded by the Office of Science and Technology within the Department of

Energy's Office of Environmental Management and under the Efficient Separations and Processing

Crosscutting Program.

Acronyms and Abbreviations

A electrode surface area

A amps

C charge

C Coulombs

CQ

concentration

of

electroactive film

Daw apparent diffusion coefficient

DOE U.S. Department

of

Energy

EIX electrochemical

ion

exchange

ESIX electrically switched

ion

exchange

F Faraday constant

HLW high-level waste

IX

ion

exchange

LLW low-level waste

NRC U.S. Nuclear Regulatory Commission

SCE saturated calomel electrode

/

time

TFE poly(tetrafluoroethylene)

V volts

vn

Contents

Summary iii

Acknowledgments v

Acronyms and Abbreviations vii

1.0 Introduction . 1.1

2.0 Work Accomplished : . . 2.1

2.1 Experimental 2.1

2.2 Results and Discussion 2.2

2.2.1 Comparison of Film Preparation Methods 2.2

2.2.2 Cesium Uptake/Elution 2.4

2.2.3 Estimation of Rates of Ion Loading and Unloading 2.9

2.2.4 Film Characterization Using Raman Spectroscopy 2.12

2.2.5 Scale-up Considerations 2.13

3.0 Conclusions 3.1

4.0 References 4.1

Appendix A.I

IX

Figures

1 The ESIX concept for metal ion loading and unloading 1.2

2 Cyclic voltammetry of a bare nickel electrode in 1 M NaNO

3

2.3

3 Cyclic voltammetry in 1 M NaNO

3

of hexacyanoferrate films prepared by three different

methods (Cycle #2) 2.3

4 Charge passed as determined by integration of a single potential cycle (Cycle #2) for

three film preparations 2.5

5 Repeated potential cycling of PNNL-1 in 1 M NaNO

3

2.5

6 Maximum charge passed as a function of cycle number for three different film

preparations (cyclic voltammetry in 1 M NaNO

3

) 2.6

7 Normalized maximum charge as a function of cycle number for three different film

preparations (cyclic voltammetry in 1 M NaNO

3

) 2.6

8 Cyclic voltammetry for a film in the cesium form and after two and 25 potential cycles

in 1 M NaNO

3

2.7

9 Cyclic voltammetry of a film in the sodium form and after two potential cycles in

1 M CsNO

3

2.8

10 Loading of a film in the sodium form in 1 M NaNO

3

and the same film in the cesium

form in 1 M CsNO

3

2.9

11 Normalized charge as a function of time for three different film preparations (from

cyclic voltammetry in 1 M NaNO

3

) 2.10

12 Potential step loading (0.25 V) and unloading (0.50 V) of a film prepared by the

literature method 2.11

13 Cottrell plot for unloading sodium from a film prepared by the literature method 2.11

14 Raman spectra of hexacyanoferrate films on a nickel wire as a function of

applied potential 2.12

15 Imaging Raman spectra of a literature film on a nickel wire showing spatially

homogeneous redox reactions 2.14

x

1.0 Introduction

A variety of waste types containing radioactive

137

Cs are found throughout the U.S. Department of

Energy (DOE) complex. These waste types include reactor cooling basins (Hanford, Savannah River),

underground storage tanks containing high-level radioactive waste (Savannah River, Idaho, Oak Ridge,

and Hanford), and occasionally groundwater (Idaho). Safety and regulatory requirements and

economic considerations necessitate the removal of radiocesium before these wastes can be permanently

disposed of as low-level waste (LLW) (Gephart and Lundgren 1995; PNNL 1996).

Underground storage tanks contain high-level mixed wastes in forms of sludge, salt cake, and

alkaline supernatant liquors. The current treatment scenario for this waste includes vitrification of the

high-level waste (HLW) for storage in a geologic repository and immobilization of the LLW for

near-surface disposal. Because of the high cost of HLW disposal, separation and concentration of the

radionuclides is needed to minimize the volume of HLW so that most of the waste may be disposed of

less expensively as LLW. Although the disposal requirements for LLW at Hanford have not been set,

the Nuclear Regulatory Commission (NRG) Class A waste form can contain no more than 1 Ci/m

3

.

Using the volume reduction achievable by the current vitrification technology, the concentration of

I37

Cs in the feed to the LLW vitrifier may be at most 0.42 Ci/m

3

(Kurath et al. 1994). Accounting for

the non-radioactive cesium in the waste (mass

137

Cs/total Cs mass = 0.38), the highest allowable total

cesium concentration in the feed would be about 9.3 x 10'

8

M. The concentration of cesium in tank

waste depends on which process generated the waste, but the highest is on the order of 5.1 x 10

4

M,

requiring the separation process to have a decontamination factor of at least 5500 (Kurath et al. 1994).

The separation must also be selective for cesium in the presence of sodium concentrations that can be

10

5

times higher.

Spent nuclear fuel storage basins and groundwater contain radioactive cesium and other radio-

nuclides at much lower concentrations. For example, the cesium concentration in groundwater at the

Test Area North at the Idaho National Engineering Laboratory is on the order of 50 ppb (3.6 x 10'

7

M)

(PNNL 1996). The K East Basin at Hanford contains about 4.3 iiCi/L (3.6 x 10"

10

M) of

137

Cs resulting

from corrosion of the fuel and its containers. A method of removing cesium is needed that avoids

transuranic loading of the ion exchange material and does not generate large quantities of secondary

waste.

Currently, the most accepted option for cesium separation before final disposal is conventional ion

exchange (IX) (Kurath et al. 1994). Both inorganic and organic ion exchangers are under consider-

ation. Unfortunately, in the current state of IX technology, a large amount of secondary waste is

generated due to the numerous process steps required (acid elution, exchanger water rinse, and sodium

loading of the exchanger). Neutralization of the acidic eluant typically adds sodium to the waste,

restricting the choice of waste form and limiting the amount of waste that can be incorporated. In

addition, it has been reported that organic exchangers lose approximately 3% of their capacity per

cycle (Kurath et al. 1994). Therefore, typical organic exchangers can be used for only 20 to 30 cycles

before they must also be disposed of as another form of secondary waste.

1.1

Electrically Switched Ion Exchange (ESIX) is an approach for radioactive cesium separation that

combines IX and electrochemistry to provide a selective and reversible separation method, which

should produce little or no secondary waste. In the ESIX process (Figure 1), an electroactive IX film

is electrochemically deposited onto a high-surface area electrode, and the IX characteristics (ion uptake

and elution) are controlled directly by modulating the potential of the film. For cesium, the

electroactive films under investigation are ferrocyanides, which are well-known ion exchangers (Barton

et al. 1958; Harjula et al. 1994; KouWm et al. 1964; Lehto and Harjula 1987; Lehto et al. 1987;

Loewenschuss 1982; Loos-Neskovic and Fedoroff 1984-1989b; Loos-Neskovic et al. 1976a, 1976b;

Prout et al. 1965; Tusa et al. 1994) having high selectivities for cesium in concentrated sodium

solutions (Barton et al. 1958; Harjula et al. 1994; Loos-Neskovic et al. 1976a, 1976b; Prout et al.

1965;

Tusa et al. 1994). A similar system using Prussian Blue films on a platinum electrode for metal

ion separations has been reported (Ikeshoji 1986). When a cathodic potential is applied to the film,

Fe

+3

is reduced to the Fe

+2

state, and a cation must be intercalated into the film to maintain charge

neutrality (i.e., cesium is loaded). Conversely, if an anodic potential is applied, a cation must be

released from the film (i.e., cesium is unloaded). Therefore, to load the film with cesium, the film is

reduced; to unload cesium, the film is oxidized.

The combination of IX and electrochemistry has been attempted previously. The most successful

attempt has been the electrochemical ion exchange (EEK) technology developed by AEA Technology,

United Kingdom (Bridger et al. 1991; Jones et al. 1992). In EIX, the IX properties of an

exchanger/electrode are controlled by generating acid and base locally by water electrolysis. ESIX is

significantly different because the uptake and elution of ionic species in a modified electrode or IX film

are controlled by modulating the potential of the film directly without changing the local interfacial pH.

+ Cs

+

+ e"

Load Cycle

Unload Cycle

Figure 1. The ESIX concept for metal ion loading and loading

1.2

Furthermore, the potentials used in this method do not result in the electrolysis of water, leading to

more efficient use of electrical energy and eliminating the safety issues associated with hydrogen

evolution.

A potential advantage of the ESIX process is that it may be possible to elute cesium into the same

elution solution after several load cycles because the unload step is conducted electrochemically without

added chemicals and independent of the soluble cesium concentration. This improved process would

result in the generation of a waste stream with a very low sodium concentration and a cesium

concentration that is limited only by solubility, radiation, and heat generation. Such a HLW feed

stream could allow consideration of a broader range of final waste forms, including those that cannot

tolerate sodium. This process also should not produce significant amounts of secondary waste

requiring disposal as LLW, since the elution, wash, and regeneration cycles typical of standard IX are

not necessary. A small amount of wash solution may be necessary, but this solution could be used in

subsequent cycles for unloading the exchanger. Ratios of the volume of generated secondary waste to

the volume of processed waste are estimated to be as low as 0.0006 for the ESIX process, or about two

orders of magnitude lower than for a typical process using CS-100 ion exchange resin.

Modification of electrode surfaces with electroactive films has been studied extensively (Andrieux

and Saveant 1980; Laviron 1980; Murray 1980, 1984). In particular, the preparation and

characteristics of ferrocyanide films have been reported by several groups (Bacskai et al. 1995;

Bocarsly and Sinha 1982a, 1982b; Humphrey et al. 1984, 1987; Itaya et al. 1986; Lasky and Buttry

1988;

Schneemeyer et al. 1985; Sinha et al. 1984). Nickel ferrocyanide films, M

2

NiFe(CN)

6

(M =

Na, K), have been prepared by dipping a nickel electrode into a Fe(CN)

6

"

3

solution, which oxidizes the

metal electrode to precipitate the electroactive film, or more commonly by electrochemically oxidizing

the nickel electrode in a Fe(CN)

6

3

solution (Bacskai et al. 1995; Sinha et al. 1984). Electrochemical

deposition gave the most reproducible films with highly reversible behavior. Bocarsly and Sinha

(1982b) found that the redox potential and electron transfer properties of the films demonstrated a

dependance on the alkali metal cation present in the supporting electrolyte, with cesium ion greatly

affecting the observed behavior. Films showed selectivity for metal cations in the order cesium >

potassium > sodium (Sinha et al. 1984); however, the main purpose of these studies apparently was

electrocatalysis (Humphrey et al. 1987), not ion separations. Selectivity is believed to be dependant on

metal ion size (Schneemeyer et al. 1985) and cation loading and unloading apparently require solvent

transport (Lasky and Buttry 1988).

The overall goal of the research reported here is to develop the ESIX technology for metal ion

separation. Initial work has focused on developing deposition methods that generate films with higher

capacity and stability. Cyclic voltammetry and chronocoulometry are used to characterize film

stability, capacity, and rates of metal ion uptake. Raman spectroscopy is being used to investigate

mechanisms of film loss. Initial results of this research are reported in Section 2.2 Results and

Discussion.

1.3

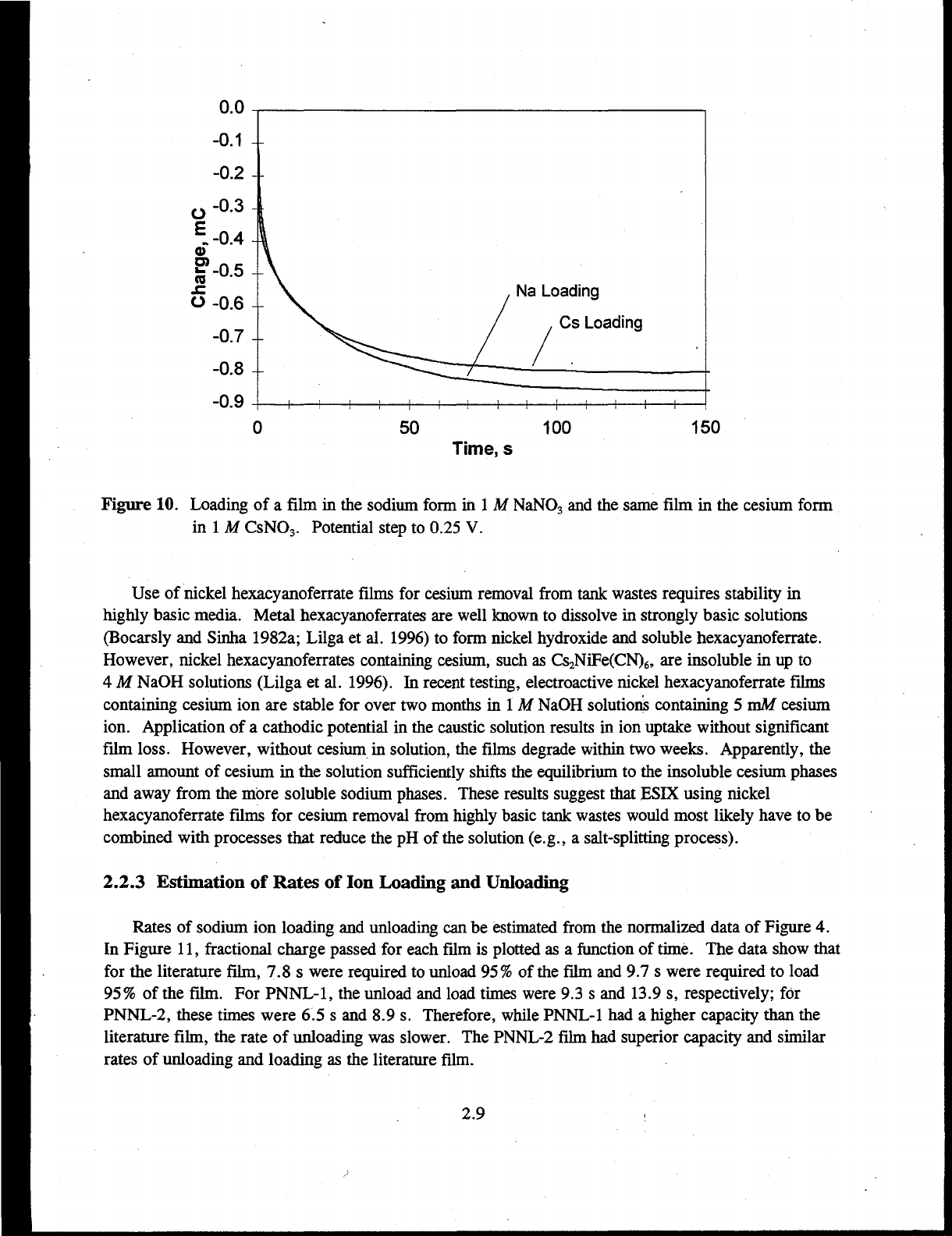

2.0 Work Accomplished

Research completed in FY 1996 focused on the preparation of electroactive hexacyanoferrate films

having improved capacity and stability. Films were prepared using modifications to the published

procedures. Testing was conducted with cyclic voltammetry, chronocoulometry, and with Raman

spectroscopy. Details of the experimental procedures are reported in Section 2.1 and findings are

discussed in Section 2.2.

2.1 Experimental

A PAR 273A potentiostat/galvanostat was used to deposit and characterize films. Potentials were

recorded versus a saturated calomel electrode (SCE). In basic solutions, a Zitex filter membrane made

of poly(trifluoroethylene) (TFE) was used in the SCE for improved stability. Experiments were

controlled and data collected with a Dell 466/MX computer via a GPIB card using LabView™ software.

A 99.98% pure nickel substrate (Goodfellow) was used as the electrode. In one experimental

setup,

disks of 1.27-cm-diameter (1.27 cm

2

) were embedded in epoxy, polished, and suspended in the

test solution. In another apparatus, a nickel plate was sealed to a specially built electrochemical cell

with an o-ring and clamp. The exposed portion of the electrode had a diameter of 1.90 cm (2.84 cm

2

).

Prior to each film deposition, the substrate was abraded using a 600-grit sandpaper and thoroughly

rinsed. Three different deposition procedures were used. One procedure was similar to that of

Bocarsly and Sinha (1982a, 1982b), where the nickel surface was exposed to a solution of 5 mM

K

3

Fe(CN)

6

and 0.1 M KNO

3

and a 1.0 V (SCE) potential was applied to the nickel electrode for 300 s.

This method is designated the "literature" procedure. One variant of this method, entailing application

of 0.65 V for 10 min followed by 1 V for 30 min, was used to prepare films for chronocoulometry

experiments. The other procedures were PNNL proprietary methods designated as PNNL-1 and

PNNL-2. All chemicals were A.C.S. reagent grade and solutions were prepared with 18.2 MQ-cm

water.

A nickel sponge electrode (Electrosynthesis Co., Inc.) with a nominal surface area per volume of

13 cm

2

/cm

3

(20 pores per inch, ppi) was also coated with a nickel hexacyanoferrate film using the

literature procedure and tested.

The characteristics of the films were determined by use of cyclic voltammetry and chrono-

coulometry. Cyclic voltammetry was typically conducted in 1 M NaNO

3

or 1 M CsNO

3

solutions

starting from an applied potential of 0.25 V, scanning anodically to 0.8 V, then cathodically to -0.1 V,

returning to 0.25 V (SCE) at a scan rate of 50 mV/s. Chronocoulometry was conducted by stepping to

0.25 V (SCE) to load the film and to 0.5 V (SCE) to unload the film, typically in 0.5

Raman spectra were acquired using the 647.1 nm line of a krypton ion laser (Laser Ionics). The

647.1 nm line is a sensitive probe of the oxidation state of the film and gives minimal film degradation

because it lies outside the absorption window of the material. Plasma emissions from the laser were

2.1

removed with a narrow bandpass filter (Omega Optical). The laser was focused using an f/10 spherical

lens.

Scattered light was collected at 90° from the incident beam by an f/1.2 Nikon camera lens. The

elastically scattered portion of the light was attenuated by an OD6 holographic notch filter (Kaiser

Optical) prior to entering the spectrograph through a 100 pm entrance slit. A 270 cm, f/4 imaging

spectrograph (Spex Industries model 270M) equipped with 600 and 1800 gr/mm gratings dispersed the

inelastically scattered light onto a liquid nitrogen cooled two-dimensional CCD array (Princeton

Instruments model LN/CCD-1024E). The spectroscopic and electrochemical instrumentation was

controlled by a Macintosh Centris 650 computer running Lab View v.2.2.1 over a GPIB interface.

Spectra were acquired in situ from 500-/mn-diameter Ni disk and wire electrodes that were coated with

a film and immersed in the sodium nitrate electrolyte. Additional details regarding the

spectroelectrochemical instrumentation have been reported previously (Haight and Schwartz 1995).

2.2 Results and Discussion

This section presents the results of studies to make films with increased capacity and stability.

Included are discussions of cesium loading and unloading and efforts to characterize the films using

Raman spectroscopy. An initial engineering evaluation is also presented.

2.2.1 Comparison of Film Preparation Methods

Films were prepared on a nickel substrate by applying an anodic potential in a solution containing

K

3

Fe(CN)

6

. The film is formed when Ni

+2

ion generated at the electrode surface reacts with the

ferricyanide anion to precipitate the insoluble nickel hexacyanpferrate material on the electrode surface

(Eq. 1). Once the electrode has been coated, it displays the properties of the nickel hexacyanoferrate,

Ni

c

K

3

Fe(CN)

6

KNiFe(CN)

6

+ 2 K

+

+ 2 e"

(1)

rather than the substrate on which it was deposited. For example, Figure 2 shows a cyclic

voltammogram of a bare nickel electrode in 1 M CsNO

3

electrolyte. Within the potential range

studied, only a small amount of current is passed associated with oxidation of the nickel surface. The

current on the 5th cycle is larger than that on the 15th cycle because the electrode surface passivates as

an oxide coating forms. Figure 3 shows cyclic voltammetry in 1 M NaNO

3

electrolyte of films

prepared by three different deposition protocols. The redox behavior of the surface-bound

hexacyanoferrate is readily apparent.

Cyclic voltammetry shows that the ferrocyanide film may be oxidized to the ferricyanide form,

which may in turn be reduced back to the ferrocyanide form. Eqs. 2 and 3, respectively, illustrate

these reactions for any alkali metal counterion (M

+

). Note that reduction requires uptake of a metal

ion, M

+

, and oxidation requires release of the ion to retain charge neutrality in the film.

M

2

NiFe"(CN)

6

-»

MNiFe

ffl

(CN)

6

+ e"

MNiFe

m

(CN)

6

+ e" + M

+

+ M

+

-» M

2

NiFe"(CN)

6

(2)

(3)

2.2

0.4-

0.3

-

0.2:

1

0.1

-

"£

oo

-

|

-0.1

-

°

-o.2:

-0.3

-

-0.4-

-0.5

-

—i—i—i—|—i—i—i—i

Cycle

5

Cycle

15

—i—i—i—I—i—i—i—i—i—i—i—i—i—

-200

0 200 400 600

Applied Potential,

mV

(SCE)

800

Figure

2.

Cyclic voltammetry

of a

bare nickel electrode

in 1 M

NaNO

3

3.5

2.5

1.5-

E

-

0.5 --

2

-0.5 -

o

-1.5

-2.5

-3.5

-200

PNNL-2

PNNL-1

Literature

H

1—I—I—I—i—I—I—I—I—I—I

1—I—| h

200

400 600 800

Applied Potential,

mV

Figure

3.

Cyclic voltammetry

in 1 M

NaNO

3

of

hexacyanoferrate films prepared

by

three different

methods (Cycle

#2)

2.3

Cyclic voltammograms in Figure 3 show that the processes in Eqs. 2 and 3 are chemically

reversible and that metal ion loading and unloading can be controlled by modulating the electrode

potential. Films in Figure 3 are initially in the reduced state (the films are loaded). During unloading

of sodium from the films, the peak current in the cyclic voltammogram occurs at about 400 mV (SCE)

and the current approaches zero at 800 Mv as oxidation of ferrocyanide to ferricyanide nears

completion. Potential scan reversal results in sodium ion uptake as ferricyanide is reduced; the peak

current occurs at about 350 mV.

Figure 3 also shows that different deposition protocols give films with different capacities, as

estimated by the charge passed, i.e., the area under the curve for each potential scan. The capacity of

each preparation is illustrated more clearly in Figure 4, which is an integration of current passed over

the course of an entire cyclic voltammetric sweep. The PNNL-prepared films using modified

deposition procedures have greater capacity than the films prepared using the standard literature

procedure. The maximum capacity of literature,

PNNL-1,

and PNNL-2 films is 2.1 x 10"

3

C/cm

2

,

2.6 x 10"

3

C/cm

2

, and 3.5 x 10'

3

C/cm

2

, respectively. These capacities correspond to surface coverages

of 2.2 x 10

8

moles/cm

2

, 2.7 x 10"

8

moles/cm

2

, and 3.6 x 10~

8

moles/cm

2

, respectively, for the

literature,

PNNL-1,

and PNNL-2 films. The thickness of PNNL-2 is approximately 540A, or about 54

unit cells deep (Loos-Neskovic et al. 1984), assuming that all sites are electrochemically active

(Bocarsly and Sinha 1982a; Sinha et al. 1984) and that the film is uniform.

Stable films were also deposited on 20 ppi (13 cm

2

/cm

3

) high surface area nickel electrodes using

the literature procedure. In characterization tests using 1 M sodium nitrate as the test solution, films on

these electrodes had surface coverages of 2.2 x 10"

8

moles/cm

2

, which was the same as that obtained

using the 1.9-cm-diameter flat plates. These results indicate that the two electrode geometries have

similar film deposition properties.

Some loss of activity occurs on repeated cycling (Figure 5). The stability of the films can be

improved, however, by modifying the deposition procedure. Figure 6 compares the maximum charge

passed for several different film preparations on 1.9-cm-diameter electrodes as a function of cycle

number. The normalized data showing fraction of charge passed as a function of cycle number is

shown in Figure 7. PNNL-2 demonstrates a loss of about 20% of its capacity after 2000 cycles. The

literature film, in contrast, lost 50% of its capacity after 2000 cycles. Finns on the 20 ppi high surface

area nickel electrodes, prepared by the literature procedure, had stabilities more like the PNNL-2

films,

losing less than 10% of their capacity after 400 cycles.

2.2.2 Cesium Uptake/Elution

The high affinity of hexacyanoferrates in the film for cesium is demonstrated by cyclic

voltammetry. Conversion of the cesium form to the sodium form requires repeated cycling in 1 M

NaNO

3

. Figure 8 shows this transformation. After two potential cycles in the unstirred solution, only

about half of the film is in the sodium form. The peak for the sodium form increases upon cycling, but

the affinity of the film for cesium is large enough that even after 25 cycles in initially pure 1 M NaNO

3

,

a peak associated with cesium uptake is still observed. The only cesium in this experiment is that

2.4

PNNL-2

PNNL-1

Literature

0

10 15 20 25

Time,

s

35

Figure 4. Charge passed as determined by integration of a single potential cycle (Cycle #2) for three

film preparations

2.5

2.0

1.5

1.0 4-

S 0.5 -

c" 0.0

^-0.5

-1.0 4-

-1.5

-2.0

-2.5

O

— Cycle #1

-- Cycle #1000

....Cycle #2000

-200 0 200 400 600 800

Applied Potential, mV (SCE)

1000

Figure 5. Repeated potential cycling of PNNL-1 in 1 M NaN0

3

2.5

o

E

ass

S>

CO

O

E

3

E

"S

CO

8.0

-

6.0-

4.0

2.0-

0.0

-

-^-

—•—-^__

—i—i—i—i—|—i—i—i—i—I—i—h-

PNNL-2

-^

-^_^_^ PNNL-1

^^^__^ Literature

^^

^

—i—i—I—i—i—i—i—

0

500

1000 1500

Cycle Number

2000

Figure 6. Maximum charge passed as

a

function of cycle number for three different film preparations

(cyclic voltammetry

in

1 M NaNO

3

)

PNNL-2

0.0

Literature

H

1—H-

0

500

1000 1500

Cycle Number

2000

Figure 7. Normalized maximum charge as

a

function of cycle number for three different film

preparations (cyclic voltammetry

in

1

M

NaNO

3

)

2.6

-0.4

-200 0 200 400 600

Applied Potential, mV (SCE)

800

Figure 8. Cyclic voltammetry for a film in the cesium form and after two and 25 potential cycles in

1 M NaNO

3

initially in the film, estimated to be about 1.6 x 10

s

moles for a 1.27-cm-diameter electrode with a

surface coverage of 6.5 x 10'

9

moles/cm

2

. These results show that low cesium concentrations compete

with high sodium concentrations for ion exchange sites in the film.

A film initially in the sodium form converts readily to the cesium form before the second potential

cycle in 1 M CsNO

3

(Figure 9). Displacement of sodium by cesium occurs during electrochemical

cycling as well as by chemical ion exchange, as in a conventional ion exchange column. In other

testing, it has been shown that as little as 5 mM cesium added to a 1 M NaNO

3

solution converts much

of the sodium form to the cesium form. Similar results were obtained by chemical analyses of films

purposely dissolved. For example, films on a 1.27-cm-diameter electrode were exposed to 5mM

CsNO

3

in 1 M KNO

3

. Dissolution of the films and analysis by atomic absorption showed significant

selectivity for cesium over potassium, but the small amount of material on the electrode precluded

accurate quantification. Similar testing is currently being conducted using high surface area electrodes

to obtain more quantitative values.

Figures 8 and 9 show that, like sodium ion, cesium ion uptake and release is also chemically

reversible. However, cesium peaks are much broader and shifted anodically. The practical

consequence is that in a process for cesium separation, loading of the film with cesium requires an

applied potential of about 0.55 V or less and unloading must be conducted at 0.60 V or greater.

Because sodium loading occurs at about 0.40 V, it is possible that selectivity for cesium over sodium

2.7

-200 0 200 400 600

Applied Potential, mV (SCE)

800

Figure 9. Cyclic voltammetry of a film in the sodium form and after two potential cycles in 1 M

CsNO

3

could be enhanced by applying the appropriate potential. The applied potential is an additional driving

force to increase the Cs/Na separation factor.

The broad anodic peak with a smaller peak current for cesium compared to sodium suggests that

unloading of cesium is slower than sodium unloading. The cation dependence of the cyclic

voltammetry, which has been seen before (Bocarsly and Sinha 1982b; Humphrey et al. 1984), suggests

that ion diffusion through the film is the rate limiting process, consistent with the known high affinity

of metal hexacyanoferrates for cesium. This high affinity forms the basis for the use of these materials

as ion exchangers for the removal of cesium from nuclear waste (Barton et al. 1958; Harjula et al.

1994;

Lehto and Harjula 1987; Loewenschuss 1982; Loos-Neskovic and Fedoroff 1989b; Tusa et al.

1994).

The high current after the anodic cesium peak in Figures 8 and 9 indicates that cesium was still

being unloaded from the film when the potential was reversed. On the time scale of the experiment,

the cesium film utilized about 73

%

of the capacity displayed by the sodium film.

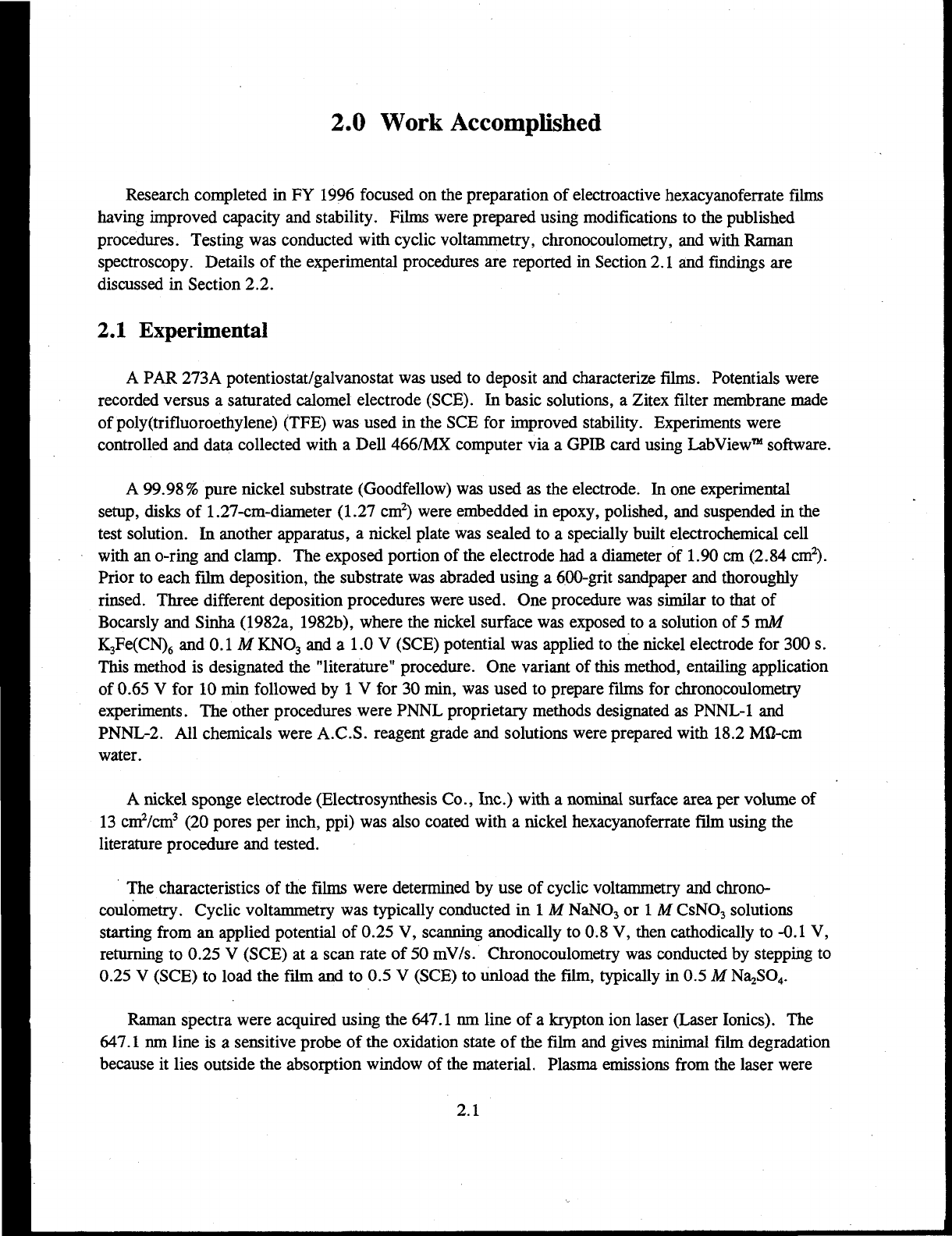

In contrast, potential step data, which are not complicated by a potential scan, indicate that the

films have about the same capacity for cesium as they do for sodium. The charge that flows during

electrochemical loading of sodium ion into a film in the sodium form, and of cesium ion into the same

film in the cesium form, at an applied potential of 0.25 V is shown in Figure 10. Charge flows until

the film is completely loaded. Both sodium and cesium loaded into the film to nearly the same extent.

The potential step experiments more closely approximate how a process based on ESIX would operate.

2.8

Na Loading

Cs Loading

50

100

150

Time,

s

Figure 10. Loading of a film in the sodium form in 1 M NaNO

3

and the same film in the cesium form

in 1 M CsNO

3

. Potential step to 0.25 V.

Use of nickel hexacyanoferrate films for cesium removal from tank wastes requires stability in

highly basic media. Metal hexacyanoferrates are well known to dissolve in strongly basic solutions

(Bocarsly and Sinha 1982a; Lilga et al. 1996) to form nickel hydroxide and soluble hexacyanoferrate.

However, nickel hexacyanoferrates containing cesium, such as Cs

2

NiFe(CN)6, are insoluble in up to

4 M NaOH solutions (Lilga et al. 1996). In recent testing, electroactive nickel hexacyanoferrate films

containing cesium ion are stable for over two months in 1 M NaOH solutions containing 5 vaM cesium

ion. Application of a cathodic potential in the caustic solution results in ion uptake without significant

film loss. However, without cesium in solution, the films degrade within two weeks. Apparently, the

small amount of cesium in the solution sufficiently shifts the equilibrium to the insoluble cesium phases

and away from the more soluble sodium phases. These results suggest that ESIX using nickel

hexacyanoferrate films for cesium removal from highly basic tank wastes would most likely have to be

combined with processes that reduce the pH of the solution (e.g., a salt-splitting process).

2.2.3 Estimation of Rates of Ion Loading and Unloading

Rates of sodium ion loading and unloading can be estimated from the normalized data of Figure 4.

In Figure 11, fractional charge passed for each film is plotted as a function of time. The data show that

for the literature film, 7.8 s were required to unload 95% of the film and 9.7 s were required to load

95%

of the film. For

PNNL-1,

the unload and load times were 9.3 s and 13.9 s, respectively; for

PNNL-2, these times were 6.5 s and 8.9 s. Therefore, while PNNL-1 had a higher capacity than the

literature film, the rate of unloading was slower. The PNNL-2 film had superior capacity and similar

rates of unloading and loading as the literature film.

2.9

0)

a.

E?

re

£

o

"o

c

o

icti

u.

0.8

-

0.6

-

0.4

-

0.2

-

0.0-

f

f\\

Literature

/

/ \ PNNL-1

-

//

i

•

II

1

-

-

-I

*—\

1 1 1 1 1

\

\

\

\

\

\

\

\

PNNL-1

\\

/ /

Literature

\

X/ / PNNL-2

i—i—i

2

^ r^i i r

10

15

20

Time,

s

25 30

35

Figure 11. Normalized charge

as

a

function

of

time

for

three different film preparations (from cyclic

voltammetry

in

1

M

NaN0

3

)

Another reported method (Humphrey

et

al. 1984; Murray 1984)

to

estimate

the

rate

of

diffusion

through the film

is to

use chronocoulometry and the integrated Cottrell equation (Eq.

4) to

determine

c

=

~-'A

(4)

an apparent diffusion coefficient,

D

m

(C =

charge

in

Coulombs;

n =

equivalents

of

charge passed;

F

=

Faraday constant;

A =

surface area

in

cm

2

; C

o

*

=

concentration

of

electroactive film

in

moles/cm

3

). The charge passed

in a

chronocoulometry experiment

in

which

a

film was loaded with

sodium

ion

at

0.25

V

then unloaded

at

0.50

V is

plotted

as a

function

of

time

in

Figure

12.

This

experiment was conducted

in

0.5

M

Na

2

SO

4

on

a

0.65-cm-diameter electrode. The film was prepared

by

the

literature method. The total charge passed was 1.57 mC during

the

load step

and 1.55 mC

during the unload step, corresponding

to

an

average surface coverage

of

4.9

x

10"

8

moles/cm

2

.

The apparent diffusion coefficient

is

determined from

a

plot

of

charge

as a

function

of

the square

root

of

time, shown

in

Figure 13

for

the unload step. The short-time data corresponds

to

the

condition

of semi-infinite diffusion

for

which the Cottrell equation

is

valid. Using

the

slope

of

the data from

20

to 50% loading,

D

m

for

unloading the film

is

calculated

to

be

1.5 x

10"

n

cm

2

/s.

A

similar analysis

of

cathodic chronocoulometry results gives

a D

m

of

8.2

x

10"

12

cm

2

/s

for

sodium ion uptake. These

diffusion coefficients

are

similar

to

those reported

by the

Bocarsly group (Humphrey

et

al.

1984).

The

difference

in

D

#

for

loading and unloading

is

thought

to

be

due

to

solvent exchange processes

(Humphrey

et

al.

1984; Lasky and Buttry 1988).

2.10

o

E

<D

W

CO

CO

Q.

0)

S?

CO

o

0.0

-

-0.4-

-0

8 -

-1.2-

-1

fi -

I

I Load

1 (0.25 V)

\

—i—i—i—i—i—I—i—i—i—

r

Unload

(0.50 V)

-i—i—i—i—i—i—i—

50 100

Time,

s

150

200

Figure 12. Potential step loading (0.25 V) and unloading (0.50 V)

of a

film prepared by the literature

method

o

of

CO

O

1.4

-

1.2

-

1.0

-

0.8

-

0.6-

0.4

-

0.2-

0.0-

-

I

-

/

I

L—i 1 1 1 1 1 1 1 1

0.0

2.0 4.0 6.0

Time

1

*,

sec

1/2

8.0

10.0

Figure 13. Cottrell plot for unloading sodium from

a

film prepared by the literature method

2.11

2.2.4 Film Characterization Using Raman Spectroscopy

Development of a process based on ESIX technology will require use of high surface area

electrodes. Associated with large electrodes are the problems of current and potential control that must

be accounted for in the engineering design of the electrochemical reactor. An issue with electroactive

films is whether redox reactions occur homogeneously or in islands on the electrode. Homogeneous

redox reactions are desirable for predictable kinetics and process control and for efficient use of the

electrode area.

The results reported here indicate that Raman spectroscopy is a sensitive probe of the oxidation

state of the film. This technique is a good diagnostic tool for in situ investigations of the behavior of

metal hexacyanoferrate films during redox reactions and should give information about mechanisms of

film deactivation or loss. When a literature film is fully reduced with an applied potential of -111 mV,

two low wavenumber cyanide stretching modes are evident at 2103 cm"

1

and 2151 cm

1

, corresponding

to the ferrocyanide oxidation state (Figure 14). As the applied potential is made more anodic, the film

is observed to become increasingly oxidized. The film is almost completely in the ferricyanide form

(peak at 2186 cm"

1

) at an applied potential of 778 mV as shown in Figure 14. Ferro- and ferricyanide

have been distinguished on potential cycling of films with thicknesses as low as about 100A (10 unit

cells thick).

c

i

i i I

i

; I

1900 2000 2100 2200 2300

Raman Shift, cm'

1

2400

Figure 14. Raman spectra of hexacyanoferrate films on a 500-/an-diameter nickel disk electrode as a

function of applied potential

2.12

Imaging Raman spectroscopy shows that the thin film redox reactions occur uniformly across the

film rather than in isolated regions. Raman images of a 750-jtm-long by 30-/xm-wide region of film

were obtained as oxidation was carried out electrochemically (Figure 15). As oxidation occurred, the

spatially uniform growth of ferricyanide species was observed. This is the first time that spatial

uniformity of a thin film redox reaction has been demonstrated in situ. These results are important for

the design of a practical ion separation system and in maintaining as uniform a current distribution as

possible at a high surface area electrode.

2.2.5 Scale-up Considerations

In FY 1997, a bench-scale system will be designed, constructed, and tested. Thus some scale-up

issues were addressed this year to prepare for the FY 1997 activities. The scale-up parameters that

were considered included electrode surface area requirements, electrode materials, cell control, cell

configuration (i.e., divided versus undivided), mode of operation (i.e., once-through versus batch

recycle), and recommended available reactor systems. Electrosynthesis Company, Inc. was asked to

assist in addressing these issues. The assumptions, calculations, and conclusions resulting from this

study are given in the Appendix. The major assumptions and conclusions are summarized below.

The major assumptions used in addressing the scale-up issues are as follows:

1.

The cesium concentration in the waste is 0.5 vaM.

2.

A uniform surface loading of 10"

7

moles/cm

2

of CsNiFe(CN)

6

should be active in the Cs insertion

process.

3.

The volume of effluent to be treated by the described cells is 10 L/h.

4.

The process objective is to remove 99% of the Cs (decontamination factor of 100).

For these assumptions, required electrode surface areas were similar when based on both ion

exchange capacity and mass transport considerations. (If initial cesium concentrations are lower than

those assumed here, for example for Hanford K-basin waste, the mass transport considerations become

more important). This suggests that both are important to consider when designing the scaled-up

system. Additionally, the required electrode surface areas were such that a three-dimensional, high

surface area electrode configuration is essential.

For the given application, commercially available nickel foam and nickel felt materials are

available. The nickel felt materials typically have specific surface areas at least a factor of 10 higher

than the foams. However, felts have random, closed packed structures that can lead to non-uniform

flow. High surface area nickel foams were recommended as the preferred electrode material. The

commercially available specific electrode areas for such foams range from approximately 35 cnrVcm

3

to 90 cnrVcm

3

.

2.13

co

2103 2151 2186

Raman Shift [cm-

1

]

Figure 15. Imaging Raman spectra of a literature film on a nickel wire showing spatially homogeneous

redox reactions

2.14

Further investigation of controlled current operation was recommended in addition to the assumed

potential control mode of operation because when a current is passed through a cell, the most readily

occurring anode and cathode reactions will take place. Based on experimental evidence and ion

exchange characteristics of ferrocyanide materials, when a cathodic current is passed through a nickel

ferricyanide film in a solution containing Na

+

and Cs

+

, Cs

+

should preferentially be taken up by the

film, and thus should be the most readily occurring reaction. To prevent excessive hydrogen or

oxygen evolution when the electrode has become fully charged or discharged, it was recommended that

either the electrode be oversized or a charge limit be put into the control.

Both batch recycle and once-through modes of operation were considered. Based on calculations,

both modes of operation were found to be applicable and practical options. Additionally, for this

application there was no advantage to using a divided cell versus an undivided cell; therefore, use of an

undivided cell was recommended. Numerous commercially available reactors were recommended for

this application.

2.15

3.0 Conclusions

This research has demonstrated the viability of ESIX for metal ion separations. Ion loading and

unloading is easily controlled by modulating the electrode potential. The use of metal hexacyano-

ferrates, which are known cesium ion exchange materials, is expected to give high selectivity for

cesium over sodium. Films are relatively easy to prepare, but modifications to the reported procedures

can generate films with significantly improved capacity and stability. The best films prepared to date

have almost twice the capacity of previously reported films and lose less than 20% of their capacity

after 2000 cycles. The ability to cycle through many load/unload cycles is important to the

development of a practical process since the absolute capacity of a film on an electrode surface is much

less than the capacity of a standard ion exchange column. Bench-scale testing is needed to determine

whether cycle time and throughput are sufficient to allow ESIX to perform on a par with standard

technologies, such as conventional ion exchange. If so, use of a regenerable material and the

minimization of secondary waste will be significant advantages in favor of the ESIX process.

Ongoing research encompasses investigating the preparation of films with higher capacity and

stability, determining the selectivity of cesium ion uptake, and designing and testing appropriate flow

reactor systems for bench-scale research. The use of Raman spectroscopy to probe film loss and

deactivation mechanisms is also continuing and a more-detailed discussion of these results will be

published in the future. Ultimately, cesium removal from real waste streams using a flow system will

be tested.

3.1

4.0 References

Andrieux, C. P. and J. M. Saveant. 1980. "Electron Transfer Through Redox Polymer Films."

Journal of Electroanalytical Chemistry 111:377.

Bacskai, J., K. Martinusz, E. Czirok, G. Inzelt, P. J. Kulesza, and M. A. Malik. 1995. "Polynuclear

Nickel Hexacyanoferrates: Monitoring of Film Growth and Hydrated Counter-cation Flux/Storage

during Redox Reactions." Journal of Electroanalytical Chemistry

385:241.

Barton, G. B., J. L. Hepworth, Jr., E. D. McClanahan, R. L. Moore, and H. H. van Tuyl. 1958.

"Chemical Processing Wastes — Recovering Fission Products." Industrial and Engineering Chemistry

102:212.

Bocarsly, A. B. and S. Sinha. 1982a. "Chemically Derivatized Nickel Surfaces: Synthesis of a New

Class of Stable Electrode Interfaces." Journal of the Electroanalytical Chemistry and Interfadal

Electrochemistry 137:157.

Bocarsly, A. B. and S. Sinha. 1982b. "Effects of Surface Structure on Electrode Charge Transfer

Properties. Induction of Ion Selectivity at the Chemically Derivatized Interface." Journal of the

Electroanalytical Chemistry and Interfacial Electrochemistry 140:167.

Bridger, N. J., C. P. Jones, and M. D. Neville. 1991. "Electrochemical Ion Exchange." Journal of

Chemical Technology and Biotechnology 50:469.

Gephart, R. E. and R. E. Lundgren. 1995. "Hanford Tank Clean up: A Guide to Understanding the

Technical Issues." PNNL-10773, Pacific Northwest National Laboratory, Richland, Washington.

Haight, S. M. and D. T. Schwartz. 1995. "In situ Imaging Raman Spectroscopy of Electrochemically

Deposited CuSCN." Journal of the Electrochemical Society 142:L156.

Harjula, R., J. Lehto, E. H. Tusa, and A. Paavola. 1994. "Industrial Scale Removal of Cesium with

Hexacyanoferrate Exchanger — Process Development." Nuclear Technology 107:272.

Humphrey, B. D., S. Sinha, and A. B. Bocarsly. 1984. "Diffuse Reflectance Spectroelectrochemistry

as a Probe of the Chemically Derivatized Electrode Interface. The Derivatized Nickel Electrode."

Journal of Physical Chemistry 88:736.

Humphrey, B. D., S. Sinha, and A. B. Bocarsly. 1987. "Mechanisms of Charge Transfer at the

Chemically Derivatized Interface: The Ni/[Ni

n

(CN)Fe

n/ra

(CN)

5

]

2/1

- System as an Electrocatalyst."

Journal of Physical Chemistry 91:586.

4.1

Ikeshoji, T. 1986. "Separation of Alkali Metal Ions by Intercalation into a Prussian Blue Electrode."

Journal of the Electrochemical Society 133:2108.

Itaya, K, I. Uchida, and V. D.

Neff.

1986. "Electrochemistry of Polynuclear Transition Metal

Cyanides: Prussian Blue and Its Analogues." Accounts of Chemical Research 19:162.

Jones,

C. P., M. D. Neville, and A. D. Turner. 1992. "Electrochemical Ion Exchange" in

Electrochemistry for a Cleaner Environment, D. Genders and N. Weinberg, Eds., The Electrosynthesis

Company Inc., East Amherst, New York, p. 207.

Koukim, V., J. Rais, and B. Million. 1964. "Exchange Properties of Complex Cyanides — I. Ion

Exchange of Caesium on Ferrocyanides;" Journal of Inorganic and Nuclear Chemistry

26:1111.

Kurath, D. E., L. A. Bray, K. P. Brooks, G. N. Brown, S. A. Bryan, C. D. Carlson, K. J. Carson, J.

R. DesChane, R. J. Elovich, and A. Y. Kim. 1994. Experimental Data and Analysis to Support the

Design of an Ion-Exchange Process for the Treatment ofHanford Tank Waste Supernatant Liquids,

PNNL-10187, Pacific Northwest National Laboratory, Richland, Washington.

Lasky, S. J. and D. A. Buttry. 1988. "Mass Measurements Using Isotopically Labeled Solvents

Reveal the Extent of Solvent Transport during Redox in Thin Films on Electrodes." Journal of the

American Chemical Society 110:6258.

Laviron, E. 1980. "A Multilayer Model for the Study of Space Distributed Redox Modified

Electrodes." Journal of Electroanalytical Chemistry

112:1.

Lehto J. and R. Harjula. 1987. "Separation of Cesium from Nuclear Waste Solutions with

Hexacyanoferrate(II)s and Ammonium Phosphomolybdate." Solvent Extraction and Ion Exchange

5:343.

Lehto, J., R. Harjula, and J. Wallace. 1987. "Absorption of Cesium on Potassium Cobalt

Hexacyanoferrate(H)" Journal of Radioanalytical and Nuclear Chemistry 111:297.

Lilga, M. A., R. T. Hallen, E. V. Alderson, M. O. Hogan, T. L. Hubler, G. L. Jones, D. J.

Kowalski, M. R. Lumetta, W. F. Riemath, R. A. Romine, G. F. Schiefelbein, and M. R. Telander.

1996.

Ferrocyanide Safety Project. Ferrocyanide Aging Studies Final Report, PNNL-11211, Pacific

Northwest National Laboratory, Richland, Washington. .

Loewenschuss, H. 1982. "Metal-Ferrocyanide Complexes for the Decontamination of Cesium from

Aqueous Radioactive Waste." Radioactive Waste Management 2:327.

Loos-Neskovic, C. and M.

Fedoroff.

1984. "Recovery of Silver from Solutions by Fixation on

Insoluble Ferrocyanides." Annales de Chimie Science des Materiaux 9:609.

4.2

Loos-Neskovic, C. and M.

Fedoroff.

1987. "Exchange Mechanisms of Silver on Nickel and Zinc

Ferrocyanides." Solvent Extraction and Ion Exchange 5:757.

Loos-Neskovic, C. and M.

Fedoroff.

1988. "Exchange Mechanisms of Alkali Ions on Zinc

Ferrocyanides." Reactive Polymers 7:173.

Loos-Neskovic, C. and M.

Fedoroff.

1989a. "Fixation Mechanisms of Cesium on Nickel and Zinc

Ferrocyanides." Solvent Extraction and Ion Exchange

7:131.

Loos-Neskovic, C. and M.

Fedoroff.

1989b. "Decontamination of Liquid Nuclear Wastes by Fixation

of Radioactive Elements on Nickel and Zinc Ferrocyanides." Radioactive Waste Management and the

Nuclear Fuel Cycle 11:347.

Loos-Neskovic, C, M.

Fedoroff,

E. Gamier, and P. Gravereau. 1984. "Zinc and Nickel

Ferrocyanides: Preparation, Composition, and Structure." Talanta 31:1133.

Loos-Neskovic, C, M.

Fedoroff,

and G. Revel. 1976a. "Use of Radioisotopes for Retention Study

on Nickel Ferrocyanide." Journal of Radioanalytical Chemistry 30:533.

Loos-Neskovic, C, M.

Fedoroff,

and G. Revel. 1976b. "Influence of Sodium Content of Nickel

Ferrocyanides on the Retention of Alkaline Ions." Radiochemistry and Radioanalytical Letters

26(1):

17-26.

Murray, R. W. 1980. "Chemically Modified Electrodes." Accounts of Chemical Research 13:135.

Murray, R. W. 1984. "Chemically Modified Electrodes." in Electroanalytical Chemistry, Vol. 13, A.

J. Bard, Ed., Marcel Dekker, Inc., New York.

PNNL. 1996. Efficient Separations and Processing Crosscutting Program 1996 Technical Exchange

Meeting, PNNL-SA-27105, Pacific Northwest National Laboratory, Richland, Washington.

Prout, W. E., E. R. Russell, and H. J. Groh. 1965. "Ion Exchange Absorption of Cesium by

Potassium Hexacyanocobalt(II)Ferrate(II)." Journal of Inorganic and Nuclear Chemistry 27:473.

Schneemeyer, L. F., S. E. Spengler, and D. W. Murphy. 1985. "Ion Selectivity in Nickel

Hexacyanoferrate Films on Electrode Surfaces." Inorganic Chemistry 24:3044.

Sinha, S., B. D. Humphrey, and A. B. Bocarsly. 1984. "Reaction of Nickel Electrode Surfaces with

Anionic Metal-Cyanide Complexes: Formation of Precipitated Surfaces." Inorganic Chemistry 23:203.

Tusa, E. H., A. Paavola, R. Harjula, and J. Lehto. 1994. "Industrial Scale Removal of Cesium with

Hexacyanoferrate Exchanger — Process Realization and Test Run." Nuclear Technology 107:279.

4.3

Appendix

Contractor Report

Electrically Controlled Ion Exchange

Dr. David Genders

Electrosynthesis Company, Inc.

72 Ward Road

Lancaster, NY 14086

A.I

REPORT TO BATTELLE PACIFIC NORTHWEST

PRELIMINARY PROBLEM ASSESSMENT

Assumptions

1.

The concentration of Cs

+

in the waste is 0.5 mM.

2.

A surface loading of CsNiFe(CN)6 which is uniform and at least a fraction of the film

equivalent to « 10"

7

moles cm"

2

should be active in the Cs

+

insertion process; this is

equivalent to « 200 monolayers or « 0.04 um.

3.

The volume of effluent to be treated by the cells described is 10 I/hour.

4.

The process objective is to remove 99% of the Cs

+

(ie. a conversion of 0.99).

The electrode areas/cell sizes are likely to increase linearly with the Cs

+

concentration and the

volume/unit time of waste to be treated. Also the electrode area required will be inversely

proportional to the loading of CsNiFe(CN)6. In general, each order of magnitude change in the

target level for removal of Cs

+

will change the required electrode area by a substantial factor (1.5

to 2, see below).

Preliminary comments

Surface area

Two considerations could determine the surface area of electrode required in the cell.

These are the mass transport of Cs

+

to the electrode surface and the ion exchange capacity of the

nickel ferrocyanide film.

In electrochemical terms, the ion exchange capacity of the surface coating would

normally be expressed as a charge density; a film containing 10"

7

moles cm"

2

has a charge

density of 10 mC cm"

2

. The minimum charge (ie. assuming 100% current efficiency) required to

remove 0.5 mM Cs

+

from 10 litres is 500 C. Therefore the minimum surface area needed is 5 x

10

4

cm

2

(ie. 5 m

2

).

No electrode reaction can occur above the rate at which the reactant reaches the electrode

surface. Hence, one can calculate the minimum electrode area from the viewpoint of mass

transport, hi fact, in a batch reactor under mass transport control the conversien is given by the

equation

conversion = c(t)/c(0) = exp -k

m

At/V

(1)

where c(t) and c(0) are the concentrations of reactant at time t and before electrolysis

respectively, k

m

the mass transport coefficient, A the electrode area, V the volume of waste to be

treated and t is the electrolysis time (all equations used in this report are taken from the book by

F.C.

Walsh "A First Course in Electrochemical

Engineering"

1

available from the Electrosynthesis

,-3

-1

'

4

cm and t = 1 hour = 3.6

Co).

In a reasonable cell design k

m

= 10" cm s" and here V = 101 = 10

x 10

3

s. Hence to reduce, the Cs

+

level to 1 % of the system input ( a conversion of 0.99) requires

A= -2.3x(-2)xlO

4

= 1.3xl0

4

cm

2

=1.3m

2

10"

3

x3.6xl0

3

To increase the conversion to 0.999 would increase the area requirement by a factor of

1.5 while a 0.9 conversion would halve the area needed. It should be stressed that the these areas

are independent of the absolute Cs

+

concentration (see above equation) because the current

density will increase linearly with concentration (the available electrode area effectively works

harder).

It can be seen that the two areas calculated from consideration of ion exchange capacity

and mass transport appear not dissimilar and hence both ion exchange capacity and mass

transport could be factors in cell design considerations. It is probable that the limiting factor is

the nickel ferricyanide loading and we would therefore stress the importance of achieving at least

the target loading.

Certainly the areas estimated from both ion exchange capacity and mass transport

considerations are so large that no practical cell could employ a flat plate electrode. A three

dimensional electrode will be essential.

Three dimensional electrode materials

Three dimensional electrodes have been fabricated from beds of spheres and other

particles, fibers, metal wools, stacks of meshes, foams, felts etc. In this project, we are looking

for materials which give both a high specific electrode area (real electrode area per unit volume)

and good mass transport. Also, since it is necessary to coat the surface with nickel ferrocyanide,

it is essential to select materials which can be uniformly and adequately coated. Because of cost,

it is not reasonable to use precious metals and our proposals are limited to nickel and either

carbon or base metal supports.

Foams are attractive materials which have been successfully employed as electrodes by

several groups. They have a uniform structure and a high porosity; hence it should be possible to

coat them. Moreover, they have a low electrical resistance and give satisfactory mass transport

coefficients. Nickel foams are available and have been used as electrodes (eg, Langlois et al., J.

Applied Electrochem., 19 (1989) 43, 51 and 736, Tissot el al 26 (1996) 211). Reticulated

vitreous carbon electrodes are perhaps more common electrode materials (eg, Pletcher et al, J.

Applied Electrochem., 21 (1991) 659 and 667 and 23 (1993) 82). Some properties relevant to

this project are summarized in table 1 and it can be seen that the properties of Ni foam and

reticulated vitreous carbon are similar. For example it can be seen that the real area of 5 x 10

4

cm for the treatment of 10 litres could be achieved with « 500 - 1000 cm of 100 ppi material.

A typical thickness of foam in electrolytic applications is 1.2 cm and hence a piece of foam 400 -

800 cm

2

would suffice. The Ni foams are available from the Electrosynthesis Co and also from

Sorapec in France. Both Ni foam and reticulated vitreous carbon have been used commercially in

the Retec technology.

Ni and carbon felts are also available from Sorapec and the Electrosynthesis Co and these

have specific surface areas at least a factor of ten higher than the foams. Certainly, values of

k

m

A

e

determined electrochemically are higher by a factor of ten for the felts than the foams and

this appears to enhance cell performance substantially. Moreover Ni felt (Electrochim Acta 32

(1987) 1303) and carbon felt (Porocell technology, pilot and laboratory scale work by the

Electrosynthesis Co and others) have been used in electrolytic cells. The problem with felts is

that they have a random, close packed structure and it can be difficult to achieve uniform

pumping rates through electrodes of any size. It is usually particularly difficult to coat such

structures uniformly and we believe that it would be much more difficult to produce an

acceptable coating of nickel ferrocyanide on the felts compared to the foams.

The foams and felts would be our preferred cathode materials although there are others

which could be tested. For example, Olin now market a three dimensional Ti material, known as

Tysar* which it may be possible to Ni plate; they are also believed to be developing a Ni (as well

as steel) based structure of this type (specific surface areas 90 - 500 cm

2

cm

3

). Sintered Ni with

various porosities are used in the battery industry and it is also possible to consider stacked mesh

electrodes or metal wools.

Clearly, the successful coating of any material with nickel ferricyanide is a requisite to

application in the electrolytic cell and the choice of cathode will depend on the coating

technology which will be developed.

CELL CONTROL STRATAGEES

Controlled potential vs controlled current

The proposal EM-50 seems to assume that the potential of the nickel ferri/ ferrocyanide

coated electrode will need to be controlled even in the scaled up technology. This would be very

expensive and appears at first sight to be unnecessary. When a current is passed through a cell,

the most readily occurring anode and cathode reaction take place. On the basis of the

voltammetry reported, there is little doubt that when a cathodic current is passed through a nickel

ferricyanide coating in a solution of Na

+

/Cs

+

, it is the Cs

+

which will go into the film. Moreover,

the reaction has another desirable feature; in a three dimensional electrode, the uniformity of the

reaction can be problem. This will not be the case here because once the film in one area of the

electrode is filled with Cs

+

, the local current will drop to zero and the Cs

+

will insertion in the

next available zone; the insertion reaction zone will move through the thickness of the electrode.

Hence, it would be possible to operate with relative thick foam electrodes, where in other

situations, much of the thickness would be inactive due to IR drop. We recommend strongly

that controlled current operation be investigated.

The preferred constant current can be determined experimentally, for example, by

voltammetry. The only likely hazard is hydrogen/oxygen evolution if electrolysis is allowed to

continued when the electrode has become fully charged/discharged with Cs

+

. Then, either the

extreme of potential or the gas evolution could damage/disrupt the nickel ferri/ ferrocyanide

film. This could be avoided by oversizing the electrode or putting a charge limit into the control

regime.

Divided vs undivided cell

There is no compelling reason to include a membrane or porous separator in the cell

design. During removal of the Cs

+

from solution the counter electrode reaction will probably be

oxygen evolution and during discharge of the nickel ferrocyanide film it will be hydrogen

evolution. Neither will interfere with the working electrode chemistry and Cs

+

will itself not

oxidize/reduce. Other trace components of the waste stream may be electroactive but this may

not be regarded as a disadvantage. Moreover, the charge put into the waste stream is small

because of the low Cs

+

. Since undivided cells are cheaper and more flexible, we recommend

the use of undivided cells.

The current from 1 cm

3

of foam may be estimated from the equation

I =

(2)

For a 0.5 mM (5 x 10~

7

mol cm"

3

) solution of Cs

+

and 100 ppi foam (for data see table 1), this

current is « 10 mA. Hence, in the designs outlined below, the current density on the counter

electrode will be 10-50 mA cm"

2

. This is a quite normal value in effluent treatment cells. In all

cell configurations, an appropriate counter electrode material will need to be selected. It will act

alternately as anode and cathode during load/release of Cs

+

and this prevent the use of some

materials. The choice might depend on the pH and composition of the waste.

Solution - once through cell or batch recycle operation

The cell may be operated either in the once through mode where the required depletion is

achieved in a single pass or by recycling a batch through the cell.

Once through operation

The solution flow is fixed at 10 liters/hour or 3.6 cm

3

s"

1

. For a reasonable mean linear

flow rate, say 1 cm s"

1

, this fixes the area of the electrolyte chamber, A

x

, at 3.6 cm

2

or 3 cm x 1.2

cm using standard materials. Assuming mass transport control, the electrode length, L, required

for 99 % removal is given by

logc

out

/cin

(3)

where Q

v

is the volumetric flow rate. Substituting values (see assumptions and table 1) into the

equation, gives an electrode length of « 50 cm for a conversion of 0.99 for a mass transport

controlled reaction. In fact, this gives an electrode volume of only 180 cm

3

. This is insufficient

to provide the area of nickel ferricyanide to accept all the Cs

+

in solution. The calculation above

suggested a requirement of 500 - 1000 cm

J

from this point of view. Changing the electrode

thickness or width to increase the electrode volume will decrease the mean linear flow rate and

hence decrease the mass transport coefficient. Even so an electrode 1.2 cm thick x 10 cm wide x

100 cm long should lead to a 99 % removal with some safety margin. This is an unusual shape

for a commercial cell but could readily be constructed.

Batch recycle operation

In this mode of operation, the 10 liters of effluent would be placed in a reservoir and this

solution would be recycled continuously through the cell. This is a convenient way to carry out

most experiments in the laboratory since it removes the relationship between electrode

dimensions and flow rate. The solution may therefore be circulated rapidly giving a much

enhanced mass transport coefficient. It also "fits" commercial cell designs. The disadvantage is

that unless the intention is to carry out batchwise the waste treatment process, it is a poor model

for scale up.

,-3

It is likely that a mass transport coefficient of 5 x 10 cm s can be achieved in, for

example, an MP or ElectroSyn cell with a foam cathode. Equation (1) would apply to this

experiment giving an area requirement for a mass transport controlled reaction would be only 2.5

x 10

3

cm

2

or a piece of foam with a volume « 30 cm

3

. Here, therefore, the factor determining

the electrode area would clearly be the surface loading of nickel ferricyanide; the area estimated

above was 5 x 10

4

cm

2

equivalent to a foam volume of« 600 cm

3

. Allowing some safety margin

would suggest w 1000 cm

3

.

Because of the dominance of the ion exchange capacity in determining electrode size,

there appears to be unusually little disadvantage in operating in the once through mode. We

therefore recommend the use of once through designs although in preliminary flow cell

experiments there is some attraction in employing a smaller volume of waste (say 1 liter) and a

small commercial cells in the batch recycle mode.

RECOMMENDED REACTOR DESIGNS

For each of the recommended commercial reactors, advertising literature is attached. Only

specific comments are attached. Throughout the suggested electrode material is nickel foam

although the alternatives described above should also be tested in at least one cell provided they

can be satisfactorily coated with nickel ferricyanide.

1.

Electrocell AB

The electrode volume and length would be readily achieved with an ElectroSyn reactor

with 5 undivided cells in series with their electrolyte chambers fitted with 4 mm thick foam and a

polymer mesh to avoid shorting of the cell. These cells are not routinely marketed with foam

electrodes but it is possible to replace the turbulence promotes with foam contacted through a

back plate. Estimated cost $6,000 for an undivided cell with projected area of 0.4 m

2

.

2.

RetecCell

This is an upgraded tank cell design which is certainly adequate at the 10 liter scale but

may not be suitable for substantial scale up or remote operation. We would suggest the RETEC

6. Cost: $7300. It is probably necessary to use non standard counter electrodes (the DSA anodes

may not be stable as cathodes).

3.

Porocell

This is normally an undivided tubular cell with most of the cylinder volume filled with a

carbon felt. A standard cell has the dimensions of 50 cm long x 18 cm diameter which would

have the required ion exchange capacity if packed with uniformly coated carbon felt or Ni foam.

Cost: $6,400 for a 1 m

2

cell and $4,500 for a 0.5 m

2

cell.

4.

Aquanautics Cell

This is another parallel plate reactor which could be modified to take a Ni foam electrode.

A standard ABC-250 cell stack with three foam working electrodes in series would give the

required electrode volume and length. Cost: $ 3,500 for a cell containing 250 cm

2

projected

electrode area.

5. Purpose Built Cells

We would also wish to consider the design and fabrication of purpose built cells with

cylindrical or rectangular geometries. Commercial cells are generally designed for processes

where mass transport is a critical consideration; with the slow flow rates which fulfill the process

requirements, it should be straightforward and cheap to develop purpose built cells.

We would stress that the employment of larger cells (1 m

2

) when the program is extended

to higher treatment rates will be cheaper per unit volume of waste. On the other hand, further

scale up is achieved by increasing the number of cells and the cell investment cost will then be

almost proportional to the number of cells.

specific electrode area/cm

2

cm"

3

mass transfer coefficientVcm s"

1

Ni foam

45ppi

60 ppi

100 ppi

35 ±9

58 + 8

92+10

RVC

Table 1

1.4 xlO"

3

1.3 xlO"

3

1.5 xlO"

3

0.9 xlO"

3

1.1 xlO"

3

1.2 xlO"

3

Specific surface areas, A

e

, estimated from pressure drop measurements and

mass transfer coefficients, k^ taken from limiting current measurements.

Data from J. Applied Electrochem., 19 (1989) 43, 51 and J. Applied

Electrochem., 21 (1991) 659. f at a mean linear flow rate of

1

cm s'

1

30 ppi

60 ppi

100 ppi

24 + 9

32 ±10

67 ±3

PNNL-11441

UC-701

Distribution

OFFSITE

2 DOE/Office

of

Scientific

and

Technical Information

Dr. Moses Attrep,

Jr.

Los Alamos National Laboratory

P.O.

Box 1663, MS J514

Los Alamos,

NM

87545

Ms.

Debra

A.

Bostick

Oak Ridge National Laboratory

P.O.

Box

2008

Oak Ridge,

TN

37831-6201

Professor Daryle Busch

University

of

Kansas

Department

of

Chemistry

Lawrence,

KS

66045

Professor Greg Choppin

Florida State University

Department

of

Chemistry

600 West College Avenue

Tallahassee,

FL

32306

Ms.

Julie

E.

Connor

U.S.

Department

of

Energy

Idaho Operations Office

765 Lindsay Blvd., Mailstop

1225

Idaho Falls,

ID

83401

Dr. Dirk Gombert

Lockheed Martin Idaho Technologies

P.O.

Box 1625,

Mail Stop 3875

Idaho Falls,

ID

83415

Mr. Kurt Gerdes

U.S.

Department

of

Energy

Program Manager

Efficient Separations

and

Processing

Office

of

Science

and

Technology

EM-53

CL

19901 Germantown Road

Germantown,

MD

20874

Mr. Scott Haight

University

of

Washington

Deptment

of

Chemical Engineering

Box 351750

Seattle,

WA

98195-1750

Dr. Jerry

L.

Harness

U.S.

Department

of

Energy

Oak Ridge Operations Office

P.O.

Box

2001, 3-MAIN

Oak Ridge,

TN

37831

Prof.

Dennis Kelsh

Gonzaga University

Department

of

Chemistry

E.

505

Boone

Ave.

Spokane,

WA

99258-0001

Prof.

KNona Liddell

Washington State University

Department

of

Chemical Engineering

Pullman,

WA

99164-2710

Mr. Phil McGinnis

Martin Marietta Energy Systems

4500-N, MS-6273

P.O.

Box

2008

Oak Ridge,

TN

37831

Distr.l

PNNL-11441

UC-701

Dr. Don Orth

124 Vivion Drive

Aiken, SC 29803

Dr. Martin Steindler

Argonne National Laboratory

9700 South Cass Avenue

Argonne, IL 60439

Dr. Dee Stevenson

3367 E. Bernada Drive

Salt Lake City, UT 84124

Dr. John Swanson

1318CottonwoodDr.

Richland,WA 99352

Dr. Ian R. Tasker

Waste Policy Institute

Quince Diamond Executive Center

555 Quince Orchard Road

Gaithersburg, MD 20878-1437

Dr. Major Thompson

Savannah River Technology Center

P.O.

Box 616

Aiken, SC 29802

Dr. Jack Watson

Oak Ridge National Laboratory

P.O.

Box 2008

Oak Ridge, TN 37831-6149

Dr. James Phelan

Sandia National Laboratories

P.O.

Box 5800, Mail Stop 0719

Albuquerque, NM 87185-0719

Dn J. A. Wright

U.S.

Department of Energy

Savannah River Operations Office

P.O.

Box A

Aiken, SC 29808

John Mathur

U.S.

Department of Energy

Office of Science and Technology

EM-53 CL

19901 Germantown Road

Germantown, MD 20874

Dr. John H. Kolts

U.S.

Department of Energy

Idaho Operations Office

765 Lindsay Blvd., Mailstop 1147

Idaho Falls, ID 83401

Dr. Ray Wymer

188A Outer Drive

Oak Ridge, TN 37831

Dr. Daniel T. Schwartz

University of Washington

Deptment of Chemical Engineering

Box 351750

Seattle, WA 98195-1750

Dr. J. David Genders

Electrosynthesis Company, Inc.

72 Ward Road

Lancaster, NY 14086-9779

Distr.2

PNNL-11441

UC-701

ONSITE

2 DOE Richland Operations Office

R. A. Pressentin K8-50

B.

M. Mauss K8-50

Lockheed Martin Hanford Company

J. N. Appel G3-21

Numatec Hanford Company

R. A. Kirkbride H5-27

rra

D.

K. Oestreich H9-10

SGN Eurisys Services Corporation

R.K. Biyani L5-31

24 Pacific Northwest National Laboratory

E. G. Baker

W. F. Bonner

G. N. Brown

J. L. Buelt

R. T. Hallen