BY ORDER OF THE

SECRETARY OF THE AIR FORCE

DEPARTMENT OF THE AIR FORCE

INSTRUCTION 91-202

20 MARCH 2020

Incorporating Change 1, 10 April 2024

Certified Current On, 10 April 2024

Safety

THE DEPARTMENT OF THE AIR

FORCE (DAF) MISHAP PREVENTION

PROGRAM

COMPLIANCE WITH THIS PUBLICATION IS MANDATORY

ACCESSIBILITY: Publications and forms are available on the e-Publishing website for

downloading or ordering at www.e-Publishing.af.mil.

RELEASABILITY: There are no releasability restrictions on this publication.

OPR: AFSEC/SEG Certified by: AFSEC/CV

(Colonel William Culver)

Supersedes: AFI 91-202, 24 June 2015

AFI 91-217, 11 April 2014

Pages: 211

This instruction implements Air Force Policy Directive (AFPD) 91-2, Safety Programs, and North

Atlantic Treaty Organization (NATO) Standardization Agreements (STANAGs) 3101, Exchange

of Flight Safety Information, and 3102, Flight Safety Cooperation in Common Ground/Air Space.

It establishes mishap prevention program requirements, assigns responsibilities for program

elements and contains program management information. It applies to all Department of the Air

Force civilian employees and uniformed members of the Regular Air Force, Air Force Reserve,

Air National Guard (ANG) and the United States Space Force (USSF). For the purposes of this

instruction, ANG and Air Force Reserve Command (AFRC) are included in all references to Major

Commands (MAJCOMs). at joint bases, Air Force units will follow the requirements in this

instruction, along with guidance contained within inter-service and/or inter-agency agreements. At

enduring and contingency locations outside the United States, follow the requirements in this

instruction so long as they do not conflict with applicable requirements from any of the following:

host nation requirements made applicable by international agreement, Overseas Environmental

Baseline Guidance Document standards, country-specific Final Governing Standards, Geographic

Combatant Command policy, environmental annex to operational order, operational plan

(OPLAN) or other operational directive. This publication may be supplemented at any level, but

all direct Supplements must be routed to the OPR of this publication for coordination prior to

certification and approval. Send major command, field command, field operating agency and direct

2 DAFI91-202 20 MARCH 2020

reporting unit (MAJCOM/FLDCOM/FOA/DRU) supplements to Air Force Chief of Safety

(AF/SE) Org Box, 9700 G Avenue, Kirtland AFB NM 87117-5670, for coordination and approval

before publication. Refer recommended changes and questions about this publication to the Office

of Primary Responsibility (OPR) using the AF Form 847, Recommendation for Change of

Publication; route AF Forms 847 from the field through the appropriate functional’s chain of

command. All requests for changes, interpretations or clarifications concerning this publication

must be forwarded through the MAJCOM/ FLDCOM/FOA/DRU safety organization, who, in

turn, as applicable, will forward to AFSEC. The authorities to waive wing/unit-level requirements

in this publication are identified with a Tier (T-0, T-1, T-2, T-3) number following the compliance

statement. See Department of the Air Force Manual (DAFMAN) 90-161, Publishing Processes

and Procedures, for a description of the authorities associated with Tier numbers. Submit requests

for waivers through the chain of command to the appropriate Tier waiver approval authority, or

alternately, to the requestor’s commander for non-tiered compliance items. Submit waiver requests

for Secretary of the Air Force, Inspector General (SAF/IG) consideration through SAF/IGI. To

meet the intent of DAFMAN 90-161, e-mail finalized waivers (AF Form 679, Air Force

Publication Compliance Item Waiver Request/Approval) to SAF/IGI (usaf.pentagon.saf-

ig.mbx.saf-igi-[email protected]l). Ensure that all records generated as a result of processes

prescribed in this publication adhere to Air Force Instruction (AFI) 33-322, Records Management

and Information Governance Program, and are disposed IAW Air Force Records Disposition

Schedule, which is located in the Air Force Records Information Management System. The use of

the name or mark of any specific manufacturer, commercial product, commodity, and/or service

in this publication does not imply endorsement by the Air Force. This publication requires the

collection and/or maintenance of information protected by the Privacy Act of 1974 authorized by

Title 29 United States Code (USC), Section 9013, Secretary of the Air Force. All records created,

collected and stored under the guidance of this instruction are subject to the provisions of the

Freedom of Information Act, as authorized by Title 5 USC § 552, Public Information; Agency

Rules, Opinions, Orders, Records, and Proceedings, and IAW DoDM 5400.07_AFMAN 33-302,

Freedom of Information Act Program. The System of Records Notice F036 AF PC Q, Personnel

Data System (PDS); F024 AF IL C Motor Vehicle Operator’s Records, and F032 AF ILE,

Enterprise Environmental, Safety and Occupational Health-Management Information System

(EESOH-MIS) are available at: https://dpcld.defense.gov/privacy/SORNS.aspx.

SUMMARY OF CHANGES

This Interim Change (IC) revises AFI 91-202 by adding the applicability to the USSF and

redesignating the publication as a Department of the Air Force Instruction (DAFI) and changes the

title to The Department of the Air Force (DAF) Mishap Prevention Program. Additionally, it

adopts changes implemented in Air Force Guidance Memorandum 2022-01, (adds report

submission guidance for the Annual Program Management Review (APMR) in paragraph 3.5

and adds obstacle course inspection guidance. This IC also revises space safety program

management applicability, expands Air Force Safety Management System (AFSMS) guidance,

replaces Table 14.5 to reflect updated Aviation Safety training, and changes Center Commander

to Program Executive Officer in Chapter 13.

DAFI91-202 20 MARCH 2020 3

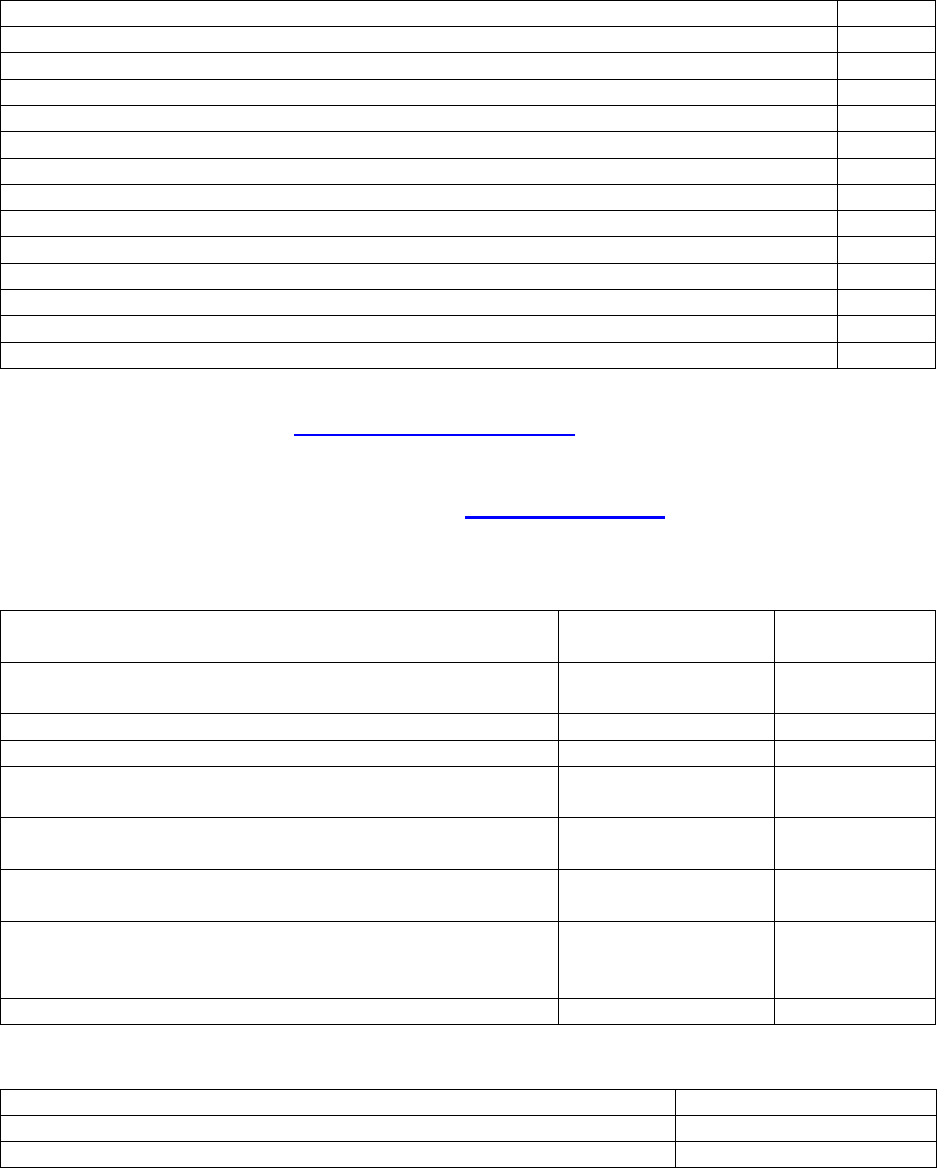

Chapter 1—PROGRAM OVERVIEW AND RESPONSIBILITIES 9

1.1. Purpose. ................................................................................................................... 9

1.2. Vision. ...................................................................................................................... 9

1.3. The Air Force Mishap Prevention Program. ............................................................ 9

1.4. Mishap Prevention Program Disciplines (Aviation, Occupational, Weapons,

Space, etc.). .............................................................................................................. 9

1.5. Air Force Occupational Safety and Health (AFOSH) Guidance and Applying

Standards. ................................................................................................................. 10

1.6. Roles and Responsibilities. ...................................................................................... 13

1.7. Waivers. ................................................................................................................... 51

1.8. Military-Unique and Nonmilitary-Unique Policy. ................................................... 51

Chapter 2—SAFETY ORGANIZATION 53

2.1. Safety Staff. ............................................................................................................. 53

2.2. Unit Safety Representative (USR). .......................................................................... 58

2.3. Safety Education/Training. ...................................................................................... 59

2.4. Safety Office Vehicles and Equipment. ................................................................... 60

2.5. Safety Library. ......................................................................................................... 60

2.6. Environment, Safety and Occupational Health Councils (ESOHC). ....................... 60

2.7. Non-USAF Councils and Committees. .................................................................... 61

2.8. Major Range and Test Facility Base (MRTFB) Safety Programs. .......................... 61

Chapter 3—SAFETY ASSURANCE 63

3.1. General. .................................................................................................................... 63

Table 3.1. Safety Evaluations, Assessments, and Inspections. ................................................. 63

3.2. Safety Evaluations. .................................................................................................. 64

3.3. Safety Program Evaluation (SPE). ........................................................................... 64

3.4. Safety Program Assessments. .................................................................................. 64

3.5. Annual Program Management Review (APMR). .................................................... 66

3.6. Annual Safety Inspections. ...................................................................................... 67

3.7. Spot Inspections. ...................................................................................................... 69

3.8. High Interest Areas. ................................................................................................. 70

3.9. Administrative Areas. .............................................................................................. 70

3.10. Special and Seasonal Inspections. ............................................................................ 70

3.11. Staff Assistance Visits (SAV). ................................................................................. 71

4 DAFI91-202 20 MARCH 2020

3.12. Federal/State Inspections and Investigations. .......................................................... 71

3.13. Contract Performance Assessment. ......................................................................... 71

Chapter 4—HAZARD IDENTIFICATION, REPORTING AND ABATEMENT 73

4.1. Hazard Identification. .............................................................................................. 73

4.2. Reporting Criteria. ................................................................................................... 73

4.3. Hazard Reporting System. ....................................................................................... 73

4.4. Additional Reporting Procedures. ............................................................................ 74

4.5. Air Force Form 457, Airmen Appeal Procedures. ................................................... 75

4.6. Risk Reduction and Mitigation. ............................................................................... 75

4.7. Preparation of Risk Assessments. ............................................................................ 75

4.8. Hazard Abatement. .................................................................................................. 76

4.9. Hazard Control Hierarchy. ....................................................................................... 76

4.10. Hazard Abatement Requirements. ........................................................................... 76

4.11. Critical/Imminent Danger Situations. ...................................................................... 77

4.12. Posting Notification of Hazards. .............................................................................. 77

4.13. Installation Master Hazard Abatement Plan (MHAP). ............................................ 78

4.14. Funding for Hazard Abatement. .............................................................................. 79

4.15. End of Year Annual Master Hazard Abatement Survey and Facility/Workplace

Inspection Report. .................................................................................................... 79

Chapter 5—INFORMATION AND DATA ANALYSIS 81

5.1. Information Protection. ............................................................................................ 81

5.2. Recurring Publications. ............................................................................................ 81

5.3. Methods of Information Distribution. ................................................................

...... 81

5.4. Mishap Analysis Program. ....................................................................................... 82

5.5. Mishap Prevention Analysis Methods. .................................................................... 82

5.6. Use of Analyzed Data. ............................................................................................. 83

5.7. Air Force Combined Mishap Reduction System. .................................................... 83

5.8. Organizational Safety Assessment (OSA). .............................................................. 84

5.9. Military Flight Operations Quality Assurance (MFOQA). ...................................... 84

5.10. Airman Safety Action Program (ASAP). ................................................................. 84

5.11. Line Operations Safety Audit. ................................................................................. 84

5.12. Standard Mishap Metrics. ........................................................................................ 85

5.13. Calculating Federal Employee Compensation Metric (Rate). ................................. 86

DAFI91-202 20 MARCH 2020 5

5.14. AFSAS Analysis and Query Tools. ......................................................................... 87

Chapter 6—DEPLOYMENT AND CONTINGENCY SAFETY 88

6.1. Deployment and Contingency Safety Program. ....................................................... 88

6.2. Air Force Forces Chief of Safety (AFFOR/SE). ...................................................... 88

6.3. AFFOR Deployed Unit Safety Functions and Organizations. ................................. 89

6.4. Mishap Prevention Program. ................................................................................... 92

6.5. Monthly, Quarterly and Annual Safety Awards. ..................................................... 92

6.6. AFFOR/SE Visits. ................................................................................................... 93

Chapter 7—AVIATION SAFETY 94

7.1. Program Management. ............................................................................................. 94

7.2. Plans. ........................................................................................................................ 94

7.3. Programs. ................................................................................................................. 94

7.4. Aero Club Operations. ............................................................................................. 97

7.5. Training Meetings and Briefings. ............................................................................ 97

7.6. Inspections/Assessments and Monitoring. ............................................................... 98

7.7. Airfield Maintenance, Construction and Waivers (Installation). ............................. 99

Chapter 8—OCCUPATIONAL SAFETY 101

8.1. Program Management. ............................................................................................. 101

8.2. Assurance Requirements. ......................................................................................... 101

8.3. Installation Occupational Safety Staff Responsibilities. .......................................... 101

8.4. Tenant Unit and Geographically Separated Unit Responsibilities. .......................... 104

8.5. Unit Safety Representative (USR) Responsibilities. ................................................ 104

8.6. Hazard Identification and Abatement. ................................................................

..... 104

8.7. Federal/State Inspections of DoD Working Conditions and Mishap

Investigations. .......................................................................................................... 105

8.8. DoL Occupational Safety and Health Administration Annual Visit Summary. ...... 105

8.9. Occupational Safety Corporate Committee. ............................................................ 105

Chapter 9—WEAPONS SAFETY 106

9.1. Program Management. ............................................................................................. 106

9.2. Weapons Safety Personnel Management and Manning Plan. .................................. 106

9.3. Explosives Safety Standards. ................................................................................... 106

9.4. Weapons Safety Personnel. ...................................................................................... 106

9.5. Weapons Safety Program Requirements. ................................................................ 109

6 DAFI91-202 20 MARCH 2020

9.6. Missile Safety. ......................................................................................................... 109

9.7. Nuclear Surety. ........................................................................................................ 109

9.8. Unit Directed Energy Safety Program Functions. ................................................... 109

9.9. Munitions Rapid Response Team. ........................................................................... 110

9.10. Department of Defense Explosives Safety Board (DDESB). .................................. 110

9.11. Weapons, Explosives and DEW Training................................................................ 110

9.12. Weapons Safety Committees. .................................................................................. 111

Chapter 10—SPACE SAFETY 112

10.1. Program Management. ............................................................................................. 112

10.2. Space Safety Responsibilities. ................................................................................. 112

10.3. Space Safety Council (SSC). ................................................................................... 113

10.4. Space Nuclear Safety. .............................................................................................. 114

10.5. Ground Based Space System Safety. ....................................................................... 114

10.6. Pre-Launch. .............................................................................................................. 114

10.7. Launch Safety. ......................................................................................................... 115

10.8. Orbital Safety. .......................................................................................................... 118

Chapter 11—SYSTEM SAFETY & SAFETY RISK ASSESSMENTS 126

11.1. Overview. ................................................................................................................. 126

11.2. System Safety Applied to Acquisition Activities. ................................................... 127

11.3. System Safety Risk Acceptance Process. ................................................................ 128

11.4. System Safety Groups (SSG). .................................................................................. 129

11.5. Non-Developmental Items.

...................................................................................... 131

11.6. System Safety Engineering Analysis (SSEA). ......................................................... 131

11.7. Application of a Safety Risk Assessment (SRA). .................................................... 132

11.8. Safety Risk Assessment Purpose and Risk Decision Authority Empowerment. ..... 132

11.9. Core Safety Risk Assessment Principles. ................................................................ 133

11.10. Safety Office SRA Reviews. .................................................................................... 135

Chapter 12—CONTRACT SAFETY 137

12.1. Contract Safety Program. ......................................................................................... 137

12.2. Contract Types. ........................................................................................................ 137

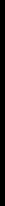

Table 12.1. Contract Considerations. .......................................................................................... 137

12.3. Contractor Compliance. ........................................................................................... 138

DAFI91-202 20 MARCH 2020 7

12.4. Safety Office. ........................................................................................................... 138

Chapter 13—SUPPORTING GUIDANCE 140

13.1. Air Force Safety Management System (AFSMS).................................................... 140

Figure 13.1. AFSMS Pillars. ........................................................................................................ 140

Figure 13.2. AFSMS Framework. ................................................................................................ 142

Figure 13.3. The Air Force 5-Step RM Process. .......................................................................... 143

13.2. Annual Program Management Review (APMR). .................................................... 146

13.3. Federal/State Inspections of DoD Working Conditions and Mishap

Investigations. .......................................................................................................... 148

13.4. USAF Aviation Safety Equipment Database Reporting. ......................................... 152

13.5. Mishap Response. .................................................................................................... 153

13.6. Job Hazard Analysis (JHA). .................................................................................... 154

13.7. Risk Assessment Codes (RAC). Note 1: .................................................................. 154

Table 13.1. Safety and Ergonomic Hazard Risk Assessment Code Matrix. ............................... 155

13.8. Abatement Priority Number (APN). ........................................................................ 156

Table 13.2. Severity and Probability Multiplier Matrix. ............................................................. 156

Table 13.3. Abatement Priority Number Index. .......................................................................... 157

13.9. Preparation of Safety Risk Assessments. ................................................................. 157

Figure 13.4. Sample Risk Assessment Layout and Guidance. ..................................................... 157

13.10. Safety Release. ......................................................................................................... 158

Figure 13.5. Safety Release Letter (Example). ............................................................................ 159

13.11. Launch Vehicle Space Debris Assessment Report (SDAR). ................................... 160

Table 13.4. SDAR Format. ......................................................................................................... 160

13.12. Combined Space Vehicle Space Debris Assessment Report/End-of-Life Plan

(SDAR/EOLP). ........................................................................................................ 163

Table 13.5. Contents of SDAR/EOLP. ....................................................................................... 164

Chapter 14—SAFETY TRAINING 168

14.1. Job Safety Training Outline. .................................................................................... 168

14.2. Continuing Education and Training Courses. .......................................................... 172

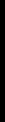

Table 14.1. Continuing Career Safety Professional Development (Recommended Safety

Courses). .................................................................................................................. 172

Table 14.2. Continuing Career Safety Professional Development (AFSEC Courses Awarding

Continuing Education Units). .................................................................................. 173

14.3. Safety Education and Training. ................................................................................ 173

8 DAFI91-202 20 MARCH 2020

Table 14.3. Mishap Investigation. ............................................................................................... 173

Table 14.4. Unit Safety Representative (USR). .......................................................................... 173

Table 14.5. Aviation. .................................................................................................................. 174

Table 14.6. Occupational. ........................................................................................................... 174

Table 14.7. Weapons................................................................................................................... 174

Table 14.8. Space. ....................................................................................................................... 174

Table 14.9. System Safety. ......................................................................................................... 174

Table 14.10. Management. ............................................................................................................ 175

Table 14.11. Risk Management (RM). ......................................................................................... 175

Table 14.12. Other. ....................................................................................................................... 175

14.4. 1S0X1 Retrainee Evaluation Process. ...................................................................... 175

Figure 14.1. 1S0 Safety Retraining Memorandum (Example). .................................................... 176

14.5. Supervisor Safety Training. ..................................................................................... 177

Chapter 15—MISCELLANEOUS SAFETY INFORMATION 179

15.1. Instructions for Completing AF Form 1118, Notice of Hazard. .............................. 179

15.2. Instructions for Completing AF Form 3, Hazard Abatement Plan. ......................... 179

15.3. Pre-Departure Travel Safety (Examples Only). ....................................................... 182

15.4. Air Force Off-Duty High-Risk Activities Program. ................................................ 183

Attachment 1—GLOSSARY OF REFERENCES AND SUPPORTING INFORMATION 185

DAFI91-202 20 MARCH 2020 9

Chapter 1

PROGRAM OVERVIEW AND RESPONSIBILITIES

1.1. Purpose. The purpose of the Air Force Mishap Prevention Program is to minimize the loss

of Air Force resources and protect Air Force personnel from death, injuries or occupational

illnesses by managing risks on and off-duty. This program is aligned with and framed using the

Air Force Safety Management System as the core structure and applies to all Air Force

organizations and personnel. The Air Force Safety Management System is a systematic approach

to managing safety and includes the necessary organizational structures, accountabilities, policies,

and procedures. The overarching mishap prevention program is system compliant with the tenants

of the American National Standards Institute Z-10 and the Federal Aviation Administration,

Aviation Safety Management Program, which were used as the foundational sources of the Air

Force Mishap Prevention Program. The Occupational Safety and Health Administration’s (OSHA)

Voluntary Protection Program is recognized as a form of a Safety Management System, and is

closely aligned with the Air Force Safety Management System. Units employing the Voluntary

Protection Program will follow the USAF mishap prevention program guidance contained within

this instruction. (T-1)

1.2. Vision. AFSEC’s vision is to be a world leader in safety management and provide care for

our Airmen, resources and our environment to meet our air, space and cyberspace missions.

Accordingly, the Air Force is committed to the following three priorities:

1.2.1. Compliance. Comply with all safety and regulatory guidelines.

1.2.2. Risk Reduction. Protect our assets, personnel and material by effectively identifying

and managing risks.

1.2.3. Continuous Improvement. Instill a culture that encourages and supports continuous

improvement.

1.3. The Air Force Mishap Prevention Program. This instruction is the foundational guidance

document for the implementation of the Air Force Mishap Prevention Program. Commanders at

all levels will adhere to these requirements unless proper waivers, deviations or exemptions are

approved as defined within this instruction. (T-1) Refer to paragraph 13.1., Air Force Safety

Management System, for additional guidance.

1.4. Mishap Prevention Program Disciplines (Aviation, Occupational, Weapons, Space,

etc.). Each mishap prevention program discipline will direct more specific functional

management responsibilities and risk management (RM) processes via AFIs, standards and

manuals, as determined applicable at the various program discipline levels. (T-1)Air Force

installation and tenant safety offices will implement these programs IAW this instruction.

(T-1)Any inter-organization and inter-service agreements will be addressed in formal support

documents. (T-1)Regardless of any support agreement or executive agency guidelines,

requirements of this instruction must be satisfied. (T-1)The mishap prevention program will

address:

1.4.1. Methods to target groups at increased risk for mishaps, injury or illness as directed by

the commander or as indicated through hazard identification processes. (T-1)

10 DAFI91-202 20 MARCH 2020

1.4.2. Processes for tracking and trending hazards and incidents, as well as methods for

determining program effectiveness. (T-1)

1.4.3. Funding for safety programs. (T-1)

1.4.4. Metrics for measuring effectiveness (See examples in Chapter 5, Information and Data

Analysis). (T-1)

1.4.5. Safety goals, objectives and milestones that support Air Force established goals. (T-1)

1.4.6. Methods to identify and disseminate safety “best practices,” “benchmarks,” etc. (T-1)

1.5. Air Force Occupational Safety and Health (AFOSH) Guidance and Applying

Standards. AFOSH guidance must be followed at all times and is the minimum guidance

necessary to provide a safe and healthful work environment for all Airmen, other Department of

Defense (DoD)/government personnel, and volunteers IAW Title 10 USC § 1588, Authority to

Accept Certain Voluntary Services, working on Air Force installations. (T-0) Air Force activities

must comply with OSHA requirements at all times unless the military-unique exemption applies

according to DoDI 6055.01, DoD Safety and Occupational Health (SOH) Program. (T-0) See

paragraph 1.8 for further guidance on military-unique and nonmilitary-unique policy. AFOSH

requirements shall provide equal or greater protection than applicable federal regulatory standards.

(T-0) All Air Force units must comply with applicable safety guidance during all Air Force

operations. (T-1) The Air Force may develop supplementary or alternative guidance where

inadequate or no federal regulatory standards are applicable. MAJCOMs, FLDCOMS, DRUs and

FOAs may supplement AFOSH guidance when additional or more stringent safety, fire prevention

or health criteria are required. When there is conflicting guidance, apply that guidance which

provides the most protection. Safety offices will maintain (or have access to) a reference library to

include national consensus standards and other mission-related technical and safety guidance.

(T-2)

1.5.1. AFOSH guidance sources include:

1.5.1.1. Regulatory Federal Standards. The Air Force complies with applicable

Department of Labor’s (DoL) OSHA, Nuclear Regulatory Commission, the National

Institute for Occupational Safety and Health (NIOSH), and Department of Transportation

standards incorporating specific requirements by reference into AFOSH guidance or

technical orders (TOs).

1.5.1.2. AFOSH Guidance. Air Force published guidance is located at http://www.e-

publishing.af.mil. The Air Force publishes industrial and general occupational safety

guidance as Air Force instructions and/or manuals, which implement applicable OSHA

standards. When AFOSH guidance or safety criteria do not cover a situation, use non-Air

Force standards including national consensus standards, professional safety and health

standards, and other federal agency standards. When there is conflicting guidance, use the

guidance that provides the most protection. Refer conflicts between OSHA, AFI, AFMAN,

AFOSH guidelines and TOs to Air Force Chief of Safety (AF/SE) through the appropriate

MAJCOM/FLDCOM/FOA/DRU safety office for resolution. (T-1)

1.5.1.3. TOs and manufacturers’ guidance (e.g., Safety Data Sheets) for specific processes,

aircraft, and equipment.

DAFI91-202 20 MARCH 2020 11

1.5.2. Joint-Use Workplaces. Personnel from different DoD Components or other federal

agencies working in the same workplace shall be governed by OSHA standards and any

applicable agency standards, host/tenant support agreements, joint base instructions, etc. (T-0)

1.5.3. Variances and Exemptions. The affected work center shall process a request for

variance or exemption when it is impractical or impossible to meet code of federal regulations

(CFR) or AFOSH requirements due to operational needs, mission impact or technical reasons.

(T-0) Variances are temporary and are granted with the understanding that permanent control

measures are planned and will be in place within a time period not to exceed five years.

Exemptions grant permanent relief from a requirement and may be approved when the

applicant can substantiate that their proposed methods, equipment or facilities protect the

employee as well or better than the AFOSH requirements or applicable. AFSEC, Air Force

Civil Engineering Center (AFCEC) and Air Force Medical (AFMED) may grant variances or

exemptions to AFOSH and environmental requirements, and AFMAN 91- 203, Air Force

Occupational Safety, Fire, and Health Standards, guidance that are more stringent than

applicable OSHA requirements. Only OSHA can grant waivers or exemptions to applicable

Title 29 (OSHA) requirements, even if they are included in AFOSH guidance. AFSEC will

serve as the liaison between OSHA and the Air Force when seeking OSHA safety- related

waivers or exemptions. Note: A unit’s inability to fund corrective actions does not constitute

sufficient justification to request a waiver, variance or exemption. Request extensions for

variances through MAJCOM/FLDCOM/FOA/DRUs to AFSEC Occupational Safety Division

(AFSEC/SEG) or AFMED Surgeon General (AFMED/SG3/5), as applicable, and appropriate.

(T-1) Variance/Exemption process consists of the following steps:

1.5.3.1. Affected work center personnel shall implement interim control measures and

notify the installation occupational safety (or tenant unit safety, if applicable), fire or health

officials to validate the effectiveness of interim controls. (T-0) With effective controls in

place, the work center will coordinate the variance/exemption package with installation

occupational safety (or tenant unit safety, if applicable), fire and health officials. (T-0)

1.5.3.2. The installation safety office (or tenant unit safety, if applicable) will assemble a

detailed staff package with the following attributes. (T-1)

1.5.3.2.1. Clearly define the safety-related variance or exemption being requested, i.e.,

a description of the situation identifying the AFOSH guidance/publication, paragraph

and specific reason(s) compliance is not possible.

1.5.3.2.2. State the rationale why the AFOSH guidance/publication cannot be

followed.

1.5.3.2.3. Provide a description and risk assessment of permanent control measures

planned, implementation date, plus identify interim control measures used to protect

personnel, equipment or property, or used to mitigate the risk or hazard.

1.5.3.2.4. Identify the number of personnel exposed and protected by interim control

measures relative to the operation or condition on a regular basis, and any Air Force

property involved.

1.5.3.2.5. A Job Hazard Analysis (JHA) will be conducted on all work processes,

where appropriate, to identify potential hazards, preventative measures in procedures

to mitigate the hazards and proper personal protective equipment (PPE), if required.

12 DAFI91-202 20 MARCH 2020

(T-0)Note: Prior to submitting a variance or exemption, a JHA should have been

accomplished to address all potential hazards. If not accomplished, provide a reason in

the variance or exemption, why a JHA was not accomplished.

1.5.3.2.6. In the case of a variance request, provide a proposed way ahead to resolve

the problem, or a description of why it is believed the problem cannot be resolved.

1.5.3.2.7. In the case of an exemption request, provide the proposed methods,

equipment or facilities to protect the employee as well as or better than the AFOSH

guidance.

1.5.3.2.8. Propose a plan to remedy the problem.

1.5.3.2.9. Include drawings, photographs, maps, etc., to clearly and thoroughly

document all of the above.

1.5.3.3. The installation safety office will forward the request to the appropriate MAJCOM

safety office through appropriate command channels. (T-1)

1.5.3.4. Any tenant unit safety staff working a variance or exemption will coordinate the

product with the installation safety office before sending it forward to the tenant unit’s

higher headquarters. (T-0)

1.5.3.5. The MAJCOM/FLDCOM/FOA/DRU safety staff reviews and, if recommended

for approval, forwards requests to AFSEC/SEG (safety-related issues), AFCEC/CC (fire

prevention and facilities-related issues) or AFMED/SG3/5 (health-related issues), as

appropriate, for final approval. Note: Requests received without MAJCOM-

FLDCOM/FOA/DRU coordination will be returned to requestor without action.

1.5.3.6. The MAJCOM, FLDCOM, FOA, DRU or installation Occupational Safety

Manager (OSM) maintains a master file of approved variances or exemptions that apply to

their MAJCOM, FLDCOM, FOA, DRU, or installation/space base delta, as long as they

are in effect and for one year thereafter. The safety manager distributes copies of variances

and exemptions to fire protection, health, and functional managers, as needed. Functional

managers or supervisors, as appropriate, must train affected employees and employee

representatives on approved variances, exemptions or any special procedures required, and

document such training. Post copies of approved variances and exemptions in affected

work areas until integrated into the Job Safety Training Outline (JSTO). (T-0)

1.5.4. Safety Changes to Technical Orders. Process recommended changes to TOs IAW TO

00-5-1, Air Force Technical Order System. Send a copy of recommended changes to Air Force

Materiel Command Occupational Safety Division (AFMC/SEG) and AFSEC/SEG.

1.5.5. Changes to Directives. Submit requests for changes to occupational safety and health

(OSH) guidelines in Air Force instructions through command channels to the directive OPR.

Safety, fire and health reviews, as appropriate, shall be accomplished at each level of command

between the requester and the directive OPR. (T-1) Send a copy of recommended changes to

AFSEC/SEG, AFCEC/CXF, and/or AFMED/SG3/5, as applicable. (T-1)

1.5.6. Occupational Health. Ensure commanders, supervisors, employees and occupational

environmental health subject matter experts assess health risks in the workplace.

DAFI91-202 20 MARCH 2020 13

1.6. Roles and Responsibilities.

1.6.1. The Assistant Secretary of the Air Force for Installations, Environment, and Energy

(SAF/IE).

1.6.1.1. The SAF/IE is the Department of the Air Force’s Designated Agency Safety and

Health Officer (DASHO). The SAF/IE delegates program responsibilities, except the

DASHO duties (which are not delegable), to the Deputy Assistant Secretary for

Environment, Safety, and Infrastructure (SAF/IEE).

1.6.1.2. Provides policy, guidance, direction and oversight of all matters pertaining to the

formulation, review and execution of plans, policies, programs and budgets relative to the

mishap prevention and Environment, Safety and Occupational Health (ESOH) programs.

1.6.1.3. Conducts Program Management Reviews of the Air Force ESOH programs, at

least annually, with the Air Force Chief of Safety (AF/SE) and the Air Force Surgeon

General (AF/SG). Reports the progress of the Air Force ESOH programs to the Deputy

Undersecretary of Defense (Personnel and Readiness), as requested.

1.6.1.4. Establishes strategic goals and objectives, develops performance measures and

assigns responsibilities in coordination with AF/SE.

1.6.1.5. Conducts Headquarters United States Air Force (HQ USAF) Environment, Safety

and Occupational Health Council (ESOHC) meetings IAW AFI 90-801, Environment,

Safety, and Occupational Health Councils.

1.6.1.6. Collects, analyzes and reports Air Force-wide performance information to Office

of the Secretary of Defense IAW DoDI 6055.01, DoDI 6055.04, DoD Traffic Safety

Program, and DoDI 6055.07, Mishap Notification, Investigation, Reporting, and Record

Keeping, as applicable.

1.6.1.7. Establishes procedures for communication with interested external parties.

1.6.1.8. IAW Headquarters AF Mission Directive 1-18, Assistant Secretary of the Air

Force (Installations, Environment and Energy), has authority over the Air Force Risk

Management Process as described in DoDI 6055.01 and AFI 90-802, Risk Management.

1.6.2. The Assistant Secretary of the Air Force for Acquisition (SAF/AQ):

1.6.2.1. Establishes engineering and technical policy and procedures for SAF/AQ

Programs (both acquisition and sustainment) to execute System Safety as an integrated part

of the Systems Engineering efforts to manage environment, safety, and occupational health

risks and requirements IAW DoDI 5000.02, Operation of the Defense Acquisition System,

and AFI 63-101/20-101, Integrated Life Cycle Management..

1.6.2.2. Coordinates guidance and federal acquisition regulations involving AFOSH

matters with AF/SE, SAF/IE and AF/SG.

1.6.2.3. Ensures contracts include applicable Federal Acquisition Regulation/DoD Federal

Acquisition Regulation Supplement/Air Force Federal Acquisition Regulation Supplement

(FAR/DFARS/AFFARS) safety clauses.

1.6.2.4. Includes ESOH Risk Management concepts and responsibilities in the education

and training of acquisition personnel.

14 DAFI91-202 20 MARCH 2020

1.6.2.5. Ensure appropriate risk acceptance authority for High-Risk system safety

assessments.

1.6.2.6. Establishes engineering and technical policy and procedures for Air Force

Acquisition and Sustainment, including policy and procedures for all programs to execute

System Safety as an integrated part of Systems Engineering.

1.6.2.7. Performs periodic reviews of Acquisition and Sustainment programs. These

include required reviews of the results of each program’s ESOH Risk Management efforts.

This ensures that System Safety is overseen within the context of other cost, schedule and

performance issues.

1.6.2.8. Represents the Air Force in Acquisition and Sustainment Program System Safety

matters with other DoD components and both Governmental and non-Governmental

agencies.

1.6.2.9. Ensures program offices support and are included in system-related Class A and

Class B mishap investigations to the extent necessary to analyze hazards that contributed

to the accident, and provide recommendations for materiel risk mitigation measures,

especially those that minimize potential human errors.

1.6.3. The Assistant Secretary of the Air Force for Financial Management and Comptroller

(SAF/FM):

1.6.3.1. Determines process for Risk Assessment Code (RAC) funding visibility, priority

and implementation procedures for funding the abatement of safety, fire and health

hazards.

1.6.3.2. Encourages use of the RAC system on Resource Allocation Programming

Information Decision System used during the corporate budgeting process.

1.6.3.3. Includes ESOH Risk Management concepts and responsibilities in the education

and training of financial management/comptroller personnel.

1.6.3.4. Ensures scoring of ESOH risk data analysis for financial project management and

programming.

1.6.4. The Air Force Surgeon General (AF/SG):

1.6.4.1. Establishes goals, objectives, policy and standards for occupational and

environmental health.

1.6.4.2. Ensures Air Force occupational and environmental health policies meet or exceed

federal regulations (CFRs) and other applicable requirements.

1.6.4.3. Develops health-related policies which support the Air Force mishap prevention

program.

1.6.4.4. Develops and facilitates use of human factors standards in mishap prevention.

Ensures use of tools that address human error identification and reduction related to fatigue,

stress and other emotional, psychological or physiological factors.

1.6.4.5. Provides subject matter experts (SMEs) in human factors.

DAFI91-202 20 MARCH 2020 15

1.6.4.6. Through the Biomedical Sciences Corps (BSC) Associate Chief for

Bioenvironmental Engineering (AFMRA/SG3PB), coordinates on installation-level

proposed responses related to occupational safety and health events.

1.6.5. The Deputy Chief of Staff Logistics, Engineering, and Force Protection (AF/A4):

1.6.5.1. Ensures maintenance and logistics policy address and comply with all applicable

safety and health standards.

1.6.5.2. Ensures Air Force procedures for storing, handling, using and transporting

hazardous materials and disposing of wastes comply with transportation regulations,

environmental statutes and occupational regulations.

1.6.5.3. Ensures civil engineering procedures, operations, technical publications and

designs for new construction meet or exceed federal regulatory requirements and AFOSH

guidance, as well as explosives and other safety criteria.

1.6.5.4. Ensures policy addresses and mitigates the potential for human error associated

with logistics and engineering activities.

1.6.5.5. Integrates ESOH Risk Management and risk reduction into the sustainment

decision-making process.

1.6.5.6. Incorporates ESOH principles in policies, procedures and training.

1.6.5.7. Determines process for RAC funding visibility, priority and implementation

procedures within the Integrated Priority List corporate process for funding safety, fire and

health hazards abatement.

1.6.6. The Deputy Chief of Staff, Manpower Personnel and Services (AF/A1):

1.6.6.1. Develops policy on personnel matters relating to AFOSH.

1.6.6.2. Provides guidance for commanders and supervisory personnel to meet

accountability and performance requirements for the AFOSH program.

1.6.6.3. Serves as the OPR for Federal Employees’ Compensation Act (FECA) at the Air

Staff level.

1.6.6.4. Establishes a process through which Airmen are evaluated on Safety and

Occupational Health (SOH) duties and responsibilities within the applicable appraisal

system.

1.6.6.5. Provides guidance to ensure supervisory personnel appraisals address SOH

conformance and reflect responsibility for the management of SOH programs in their area

of responsibility. Such appraisals should specifically include an evaluation of their SOH

program management performance.

1.6.6.6. Incorporates AFOSH program orientation into training programs for new civilian

employees.

1.6.7. Headquarters, Air Force Directorate of Test and Evaluation (AF/TE). Provides direction

and guidance to ensure test organizations assess safety standards and hazards prior to testing.

1.6.8. The Deputy Chief of Staff for Operations (AF/A3):

16 DAFI91-202 20 MARCH 2020

1.6.8.1. Develops policy and guidance for use and management of AF-operated

operational ranges.

1.6.8.2. Ensures applicable environmental, safety and operation health programs and

requirements are incorporated within operational range AFPDs, AFIs, and AFMANs.

1.6.9. The Air Force Chief of Safety (AF/SE):

1.6.9.1. Is the OPR for Air Force safety programs.

1.6.9.2. Directs implementation of Public Law, Executive Orders, and DoD Directives and

Instructions on safety.

1.6.9.3. Directs implementation of the Air Force Mishap Prevention Program.

1.6.9.4. Emphasizes safety management strategies to drive mishap prevention program

and safety management system requirements.

1.6.9.5. Provides direct liaison with MAJCOM/DRU/FOA Directors of Safety on mishap

prevention program and safety management system implementation by providing training,

SMEs and incorporating safety management system principles into existing training

courses.

1.6.9.6. Serves as the lead agent for the overall cross-functional integration and

sustainment effort of Air Force safety risk management processes and procedures IAW

AFI 90-802 requirements.

1.6.9.7. Attends or delegates attendance to the Joint Service Safety Council.

1.6.9.8. Establishes and chairs or delegates chairmanship of the Air Force Senior Safety

Advisory Council.

1.6.9.9. Assigns the Chief of Occupational Safety as the USAF OSHA Process Manager.

1.6.9.10. Ensures SAF/AQ program offices are included in system-related Class A and

Class B mishap investigations to analyze hazards that contributed to the accident, and

provides recommendations for materiel risk mitigation measures, especially those that

minimize potential human errors.

1.6.10. The Air Force Safety Center, under the command of the AF/SE:

1.6.10.1. Develops, implements, oversees and funds, as appropriate, Air Force Mishap

Prevention Programs within the framework of the Air Force safety management system.

1.6.10.2. Develops safety programs, policies, goals and objectives, and establishes

guidelines to support and assess effectiveness of the mishap prevention program.

1.6.10.3. Acts as liaison for safety matters with DoD components, federal agencies and

private sector groups.

1.6.10.4. Prepares and publishes Air Force Instructions covering Air Force-unique

operations and provides implementation guidance for applicable standards.

1.6.10.5. In conjunction with AF/SG and AFCEC, develops special guidance for Air Force

operations where federal regulations, AFI and AFOSH guidance is not available or is

inadequate.

DAFI91-202 20 MARCH 2020 17

1.6.10.6. Serves as the approving authority and repository for all safety-related variances

and exemptions within the Air Force.

1.6.10.7. Coordinates testing to ensure Air Force compliance with DoD Explosives Safety

standards.

1.6.10.8. Develops procedural rules to ensure compliance with DoD and Department of

Energy (DoE) rules related to nuclear systems.

1.6.10.9. Coordinates, facilitates, develops and provides safety education and training

where appropriate.

1.6.10.10. In coordination with MAJCOMs-FLDCOMs/DRUs/FOAs, ensures identified

safety hazards and deficiencies are managed within the hazard abatement program

(Chapter 4, Hazard Identification, Reporting and Abatement).

1.6.10.11. Performs safety evaluations of MAJCOMs, FLDCOMs, DRUs, and FOAs with

a safety staff at least every 48 months.

1.6.10.12. Collects annual OSHA 300, Log of Work-Related Injuries and Illness, and

OSHA Form 300A, Summary of Work-Related Injuries and Illness, for submission to the

Bureau of Labor and Statistics by 30 May each year.

1.6.10.13. Manages the Air Force Combined Mishap Reduction System (AFCMRS)

survey process and conducts Organizational Safety Assessments (OSA) of organizations

or wings, as requested by commanders.

1.6.10.14. Reviews records disposition for functional records IAW AFMAN 33-363,

Management of Records, and 29 CFR Part 1904, Recording and Reporting Occupational

Injuries and Illnesses.

1.6.10.15. Provides and maintains a centralized suite of mishap reporting, data collection

and analytical tools or resources for use at all levels of the Air Force Safety enterprise.

1.6.10.16. Conducts specialized analyses and studies at the request of the Congress, Chief

of Staff of the Air Force, Air Force Chief of Safety, Headquarters Air Force, and

MAJCOM-FLDCOM/DRU/FOA Commanders.

1.6.10.17. Provides discipline specific subject matter experts in safety.

1.6.10.18. Coordinates with applicable agencies to ensure safety requirements and issues

(e.g., safety related FAR clauses) are addressed in guidance and directives.

1.6.10.19. Serves as consultants on assessments, evaluations and mitigation of human

factors and human performance hazards.

1.6.10.20. Performs Air Force-level trend analysis of mishaps, incidents, risk, hazards and

errors, and publishes results.

1.6.10.21. Serves as safety consultants for safety related investigations.

1.6.10.22. Maintains and upgrades the Air Force Safety Automated System (AFSAS)

program, database and all associated information technology tools necessary for AFSAS

operation and maintenance.

18 DAFI91-202 20 MARCH 2020

1.6.10.23. Serves as the lead agent for the overall cross-functional integration and

sustainment effort of Air Force Risk Management processes and procedures IAW AFI 90-

802.

1.6.10.24. Conducts the Air Force Senior Safety Advisory Council.

1.6.10.25. Conducts the Air Force Occupational Safety Corporate Committee.

1.6.10.26. Conducts the Air Force Space Safety Council.

1.6.10.27. Conducts the Air Force Aviation Safety Council.

1.6.10.28. Develops, implements and oversees the Air Force OSHA Process Management

system for the cross-functional integration and execution of occupational safety and health

events and procedures for Federal or State programs. Coordinates on installation- level

proposed responses related to occupational safety and health events.

1.6.10.29. Develops and publishes yearly high-interest spot inspection areas

(Occupational Safety Emphasis items), using five years of on-duty ground mishap data

analysis as part of the Occupational Safety Annual Program Management Review.

1.6.10.30. Publishes OSHA Cross-tells for each notice of violation received by an

installation to share data across the Air Force and DoD to support mishap prevention and

reduction efforts. (T-1) Cross-tells may be published to reinforce effective safety programs

identified during occupational safety and health events.

1.6.10.31. Develops and coordinates System Safety policy and guidance.

1.6.10.32. Evaluates safety risk assessment portions of High-Risk and Serious-Risk

acceptance packages for systems safety analysis. Reviews and coordinates on the High-

Risk acceptance packages before submission to SAF/AQ.

1.6.10.33. Provides independent assessments and advice on overall Acquisition and

Sustainment Program safety (residual hazards and associated risks) to Headquarters Air

Force senior leadership, as appropriate.

1.6.10.34. Participates in Headquarters Air Force (HAF)-level reviews for Acquisition and

Sustainment Programs. These reviews are one of the key opportunities to influence System

Safety in Acquisition and Sustainment Programs.

1.6.10.35. Represents the Air Force in system safety policy and guidance matters with

other DoD components and other government and non-government agencies.

1.6.10.36. Develops and implements System Safety training programs.

1.6.10.37. Provides advisors and consultants to System Safety Groups.

1.6.10.38. Reviews Air Force technical and management documents (capabilities

management documents, program management directives, System Safety Group charters)

for inclusion of appropriate safety requirements.

1.6.10.39. Reviews and comments on mishap reports for technical content and lessons

learned.

1.6.10.40. Provides members, advisors and consultants to the Non-nuclear Munitions

Safety Boards, Laser System Safety Review Board and safety study groups for terrestrial

DAFI91-202 20 MARCH 2020 19

nuclear reactors. Provides a senior advisor to the chair of the US Air Force Nuclear

Weapons System Safety Group. Refer to AFI 91-205, Nonnuclear Munitions Safety Board,

and AFI 91-102, Nuclear Weapon System Safety Studies, Operational Safety Reviews, and

Safety Rules.

1.6.10.41. Evaluates the System Safety of Directed Energy Weapons needed for Air Force

operations via the Directed Energy Weapons Safety Board. This safety consideration is a

System Safety effort which considers the Directed Energy Weapons hazard posed to

Airmen and all pertinent Air Force equipment. Safety of a Directed Energy Weapon device

shall be considered before purchase or during design, using AFI 91-401, Directed Energy

System Safety, for safety design criteria.

1.6.10.42. For system-related mishaps, determines whether the Program Manager

previously identified the hazards that played a role in the mishap sequence and had

included those hazards in its Systems Engineering ESOH Risk Management efforts.

1.6.11. Program Executive Officers (PEOs) ensure that programs within their portfolios are

integrating ESOH concerns into the overall systems engineering process using the system

safety methodology in Military Standard (MIL-STD)-882E, DoD Standard Practice for

System Safety, as required by DoDI 5000.02, Operation of the Defense Acquisition System, and

AFI 63-101/20-101, Integrated Life Cycle Management. They perform periodic program and

technical reviews of programs within their portfolios. These required reviews include the

results of each program’s System Safety and safety Risk Management efforts. This ensures

that System Safety is overseen alongside other cost, schedule and performance issues. PEOs

are the acceptance authorities for “Serious” program safety risks and coordinate on “High”

program safety risks.

1.6.12. MAJCOM/DRU/FOA/Numbered Air Force (NAF)/Center Commanders/Directors:

1.6.12.1. Direct implementation and provide resources for the mishap prevention program.

1.6.12.2. Establish and maintain a safety program that provides a safe and healthful

workplace. Ensure command guidelines meet or exceed applicable safety program

requirements.

1.6.12.3. Ensure subordinate commanders enforce compliance with occupational safety

and health requirements.

1.6.12.4. Ensure a process is in place for new commanders to receive training on their

safety responsibilities.

1.6.12.5. Ensure procedures are developed to identify command mishap trends and direct

actions and resources in order to establish goals and objectives to reverse identified adverse

mishap or safety program trends.

1.6.12.6. Ensure safety program performance is included in rating of subordinate

commanders, and senior civilian supervisory personnel’s performance using guidance

provided by AF/A1 as called for in paragraph 1.6.6.2.

1.6.12.7. Advocate with applicable organizations for funding priorities for hazard

abatement projects during the MAJCOM corporate planning, programming and budgeting

process.

20 DAFI91-202 20 MARCH 2020

1.6.12.8. Coordinate safety directives, instructions and supplements with the AF Safety

Center. Subordinate unit supplements will be approved by their parent command.

MAJCOM-FLDCOM programming plans, safety annexes, Concept of Operations, etc.,

should be shared with the Safety Center and MAJCOM-FLDCOM safety staffs as cross-

feed items. When such documents impact other commands, coordination with the Safety

Center is required.

1.6.12.9. Ensure command personnel are aware of commander’s goals and related

expectations for safety.

1.6.12.10. Ensure contracts include provisions requiring contractors to maintain an

effective safety and health program on Air Force-owned sites that complies with applicable

DoL, DoD, and Air Force safety standards.

1.6.12.11. Ensure all personnel are provided requisite formal and informal training

courses, educational programs and other activities to enable them to meet their respective

mishap prevention responsibilities.

1.6.12.12. Ensure conduct of the MAJCOM Environment, Safety and Occupational Health

Council adhere to requirements of AFI 90-801.

1.6.12.13. Support and ensure installations execute cooperative efforts to reduce injuries

and illnesses across the Air Force by implementing safety and occupational health

management systems throughout their command.

1.6.12.14. Convene Safety Investigation Boards and receive out briefs IAW AFI 91-204,

Safety Investigations and Hazard Reporting.

1.6.13. MAJCOM/DRU/FOA/NAF/Center Safety Staffs:

1.6.13.1. Oversee implementation of the mishap prevention program within their

organization.

1.6.13.2. Evaluate management, implementation and effectiveness of the Air Force

Mishap Prevention Program within the command IAW this instruction.

1.6.13.2.1. Ensure the evaluation criteria includes a qualitative rating system with

written criteria, to measure compliance, adequacy and effectiveness of the safety

program and safety management system.

1.6.13.2.2. Report results directly to MAJCOM-FLDCOM/DRU/FOA/NAF/Center

Commander/Directors. Based on assessment/evaluation results, identify opportunities

for continuous improvement.

1.6.13.2.3. Track program evaluation deficiencies and monitor corrective actions until

closure.

1.6.13.2.4. Review and analyze applicable mishap reports from other organizations for

lessons learned. Distribute mishap prevention data and other safety related

communications to subordinate units. Note: Lessons learned can be viewed via the

AFSEC SharePoint®.

1.6.13.3. Assist and advise commanders and supervisors at all levels to understand their

responsibility to ensure plans, procedures, facilities, equipment modifications/acquisitions,

DAFI91-202 20 MARCH 2020 21

hardware, software, and operations receive a safety review and incorporate effective risk

management, hazard elimination/mitigation and mishap reduction features.

1.6.13.4. Represent the cross-functional interest of their command during applicable

councils, committees, and meetings, e.g., Senior Safety Advisory Council, Occupational

Safety Corporate Committee, Non-Nuclear Munitions Safety Board, Explosives Safety

Committee, Flight Safety Corporate Committee, and Space Safety Council.

1.6.13.5. Coordinate with appropriate staff agencies to ensure explosives site plans comply

with explosives and other safety criteria.

1.6.13.6. Advocate for funding of safety training for command safety personnel. Maintain

a current list of safety training courses required/completed by each career safety

professional, as defined by paragraph 2.1.2, to include name of course(s), date courses

completed and courses required. MAJCOMs-FLDCOMs/FOAs/DRUs can delegate

tracking of training.

1.6.13.7. Coordinate, facilitate, develop and provide safety education and training and

required funding to assist command safety personnel in meeting their continuing education

unit (CEU) requirements through various funding sources available, i.e., civilian personnel,

base level civilian training, Air Force Personnel Center (AFPC), Federal Safety and Health

councils, as well as organizational funding.

1.6.13.8. Evaluate local On-the-Job Training (OJT) and continuation training of safety

personnel during safety program evaluations.

1.6.13.9. Review all Class A and B mishap investigation reports for thoroughness and

accuracy. (T-1) Class C and below reports may be released at the convening authority level

without MAJCOM-FLDCOM review. Ensure the findings, causes and recommendations

of reports comply with the direction in AFI 91-204 and the applicable manuals: AFMAN

91-221, Weapons Safety Investigations and Reports, AFMAN 91-222, Space Safety

Investigations and Reports, AFMAN 91-223, Aviation Safety Investigations and Reports,

and AFMAN 91-224, Ground Safety Investigations and Reports.

1.6.13.10. Ensure a process is in place to identify, train and track training of potential

safety investigation board members within the MAJCOM staff.

1.6.13.11. Ensure all personnel with access to privileged safety information receive annual

training on the proper handling procedures and document the training. Note: For those

with AFSAS accounts, training may be recorded in their AFSAS Training Module.

1.6.13.12. Assist commanders and functional managers on implementation and integration

of risk management language into command operations and instructions to include risk

assessment processes.

1.6.13.13. Develop and submit supplements for organization unique AFI and AFOSH

guidance to AFSEC for approval prior to publication. Supplements must delineate methods

for accomplishing safety program management responsibilities and should consider

guidance on:

1.6.13.13.1. The process for scheduling and conducting commander-requested Staff

Assistance Visits (SAVs) for subordinate units.

22 DAFI91-202 20 MARCH 2020

1.6.13.13.2. Conduct analysis at the installation level and below. Safety staffs should

use available resources to identify and analyze mishap trends and guidance and present

to subordinate units and commanders for mishap prevention.

1.6.13.13.3. Command mishap tracking and recommendation procedures IAW AFI

91-204.

1.6.13.13.4. Review of safety alert messages (which could come from a number of

sources, e.g., manufacturers, users, Program Managers) and verify subordinate units

take appropriate actions.

1.6.13.13.5. Coordinating and processing annual and recurring safety awards in

accordance with AFMAN 36-2806, Awards and Memorialization Program. Air Force

Safety Award Guide functional community awards criteria can be located online at

https://www.safety.af.mil/Home/Safety-Awards/. The eligibility criteria and

submission procedures for Air Force level awards, functional community awards, and

awards sponsored by other Federal agencies and non-Federal entities are provided

online at https://access.afpc.af.mil/.

1.6.13.13.6. Providing command unique training to subordinate units’ safety staff.

1.6.13.13.7. Responsibilities and/or expectations of the NAFs in regards to the

management and implementation of the Air Force Mishap Prevention Program.

1.6.13.14. Providing MAJCOM-unique requirements to subordinate units for

implementation into local Air Force Supervisor Safety Training (SST) classes.

1.6.13.15. Coordinates the cross-functional integration and execution of occupational

safety and health events, responses and procedures as prescribed within this instruction.

1.6.13.16. Consider designating high interest areas for spot inspections using their

MAJCOM-specific mishap trends and the AFSEC Occupational Safety Emphasis Items.

1.6.13.17. Provide direction and guidance identifying documentation, by discipline, which

must be uploaded in the unit’s Management Internal Control Toolset (MICT). Refer to AFI

90-201, The Air Force Inspection System, and AFI 33-360 for additional guidance.

1.6.13.18. Review and supplement, as needed, the Occupational Safety Emphasis Items

based on MAJCOM-specific mishap trends. Prescribe these emphasis items to subordinate

installations for inclusion in their High Interest Spot Inspection program.

1.6.13.19. Each MAJCOM with acquisitions not accomplished by SAF/AQ programs

must appoint a trained System Safety Manager to act as the point of contact to facilitate

System Safety matters.

1.6.13.19.1. Specify any requirements for safety features that could reduce risk,

hazards or their effects. Safety personnel must identify particular safety constraints as

early as possible to the Program Office, preferably as a part of a formal requirements

document, endorsed by the Lead Command’s proponent office for the system. These

System Safety constraints could affect the command mission, base locations, unique

operational use, support concepts or meteorological operating environments dealing

with the weapons system.

DAFI91-202 20 MARCH 2020 23

1.6.13.19.2. Participate as System Safety Group (SSG) members and System Safety

Working Group (SSWG) members, as appropriate. Ensure the Programmatic

Environment, Safety and Occupational Health Evaluation (PESHE) includes adequate

operational safety criteria and meets the DoDI 5000.02 requirements. Ensure material

mishap recommendations are included in the Lead MAJCOM cycle and efforts/results

are addressed by program offices.

1.6.13.19.3. Designate a trained focal point in the MAJCOM Safety Office responsible

for System Safety advocacy for the Command. Provide AFSEC Flight Safety Division

(AFSEC/SEF), AFSEC/SEG, AFMC System Safety Branch (AFMC/SES) and Air

Force Space Command System Safety Branch (AFSPC/SEK) (space programs only)

with the name of the focal point. Note: Trained focal point is someone who has

completed a formal System Safety course.

1.6.13.19.4. Work closely with non-SAF/AQ program managers to facilitate the Lead

Command’s coordination role in the System Safety risk acceptance process. Jointly

determine the overall level of risk and document the acceptance of this risk level with

the appropriate authorities.

1.6.13.19.5. Use the principles of system safety to discover previously unidentified

hazards and/or changes in the level of risks in fielded systems. Provide relevant

information to the program manager for risk mitigation efforts.

1.6.13.20. Lead Commands will consolidate Using Command’s requirements and

represent these needs to program offices.

1.6.14. Air Force Materiel Command (AFMC) and United States Space Force (USSF):

1.6.14.1. Develop policy and provide guidance on applying System Safety management

and engineering.

1.6.14.2. Identify and correct product safety deficiencies, give technical assistance to

mishap investigation boards, and implement corrective action involving materiel safety

aspects of mishap reports as required by AFI 91-204. Manage budgets provided for mishap

investigation support.

1.6.14.3. Ensure system, aviation, space, occupational, directed energy, and

weapons/explosives safety experts are consulted early in the life cycle of acquisition

programs.

1.6.14.4. Maintain a master hazard abatement program for centrally procured systems and

equipment applied to end products.

1.6.14.5. Ensure design criteria complies with commercial standards, military

requirements and joint standards, as well as applicable AFOSH and/or OSHA

requirements.

1.6.14.6. Periodically review design handbooks, TOs, military specifications, military

standards, and Allowance Standards (AS) to ensure safety and health criteria and

procedures in those documents comply with safety guidance. Ensure human factors and

reduction of human error potential are factored into the system design, through the use of

System Safety Groups, Human Factors review, etc., and based upon inputs from System

Safety and Human Systems Integration activities.

24 DAFI91-202 20 MARCH 2020

1.6.14.7. Monitor the Government Industry Data Exchange Program, distributes

information and corrective action to eliminate or reduce use of hazardous products.

1.6.14.8. Develop and encourage use of human factors standards in mishap prevention.

1.6.14.9. Ensure use of tools that address human error identification and reduction related

to fatigue, stress, and other emotional, psychological or physiological factors.

1.6.14.10. Establish and maintain the Air Force's capability to support system safety

efforts on major weapon system acquisitions.

1.6.14.10.1. Develop and coordinate MAJCOM centric guidance and policy for system

safety.

1.6.14.10.2. Ensure program offices and the lead and using commands coordinate

when modifications or changes in system use affect safety.

1.6.14.10.3. Evaluate mishaps and mishap trends to identify deficiencies that engineers

and managers may have overlooked or incorrectly analyzed during system

development.

1.6.14.10.4. Specifically, notify AFSEC of Program Lead System Safety Manager

assignment and location.

1.6.14.10.5. Ensure level of support, training and experience of System Safety staff is

appropriate for each Program.

1.6.14.10.6. Ensure all Center system safety managers annually report RM policies

conforming to paragraph 11.1.3, along with a current list of all Component

Acquisition Executive (CAE)- or Program Executive Officer (PEO)-accepted risks for

their programs. Provide a consolidated annual report for all programs to AF/SE and

SAF/AQ.

1.6.14.10.7. Appoint a trained System Safety manager to act as the point of contact to

facilitate system safety matters.

1.6.14.10.8. Air Force Materiel Command:

1.6.14.10.8.1. Ensures Centers document safety criteria and hazards identified

during their efforts throughout the program life cycle. Provides support as required

to ensure the responsible organizations include a safety hazard analysis with any

development or modification to be evaluated, assessed or tested within AFMC and

the using command.

1.6.14.10.8.2. Facilitates information exchange between AFMC Centers, HQ

AFSEC and the user to maintain operational safety of AFMC managed weapon

systems and end items.

1.6.14.10.8.3. Ensures AFMC/SES forwards to AFSEC/SEFE not later than 1

November in every even-numbered year, an update to the USAF Aviation Safety

Equipment Database in the format described in paragraph 13.4., USAF Aviation

Safety Equipment Database Reporting, reflecting fleet status on the last day of the

preceding fiscal year.

1.6.14.10.8.4. AFMC/SES is responsible for System Safety Engineering Analysis

DAFI91-202 20 MARCH 2020 25

efforts but may delegate these as required.

1.6.14.10.8.5. AFMC/SES shall ensure each Center has a designated Center

System Safety Manager (CSSM).

1.6.14.10.9. Air Force Space Command. Ensures launch and on-orbit hazards are

identified. Provides input to the acquisition framework to ensure system safety is

considered throughout the space system life cycle.

1.6.15. Air Education and Training Command (AETC):

1.6.15.1. Reviews new and revised technical training course specialty and job qualification

training objectives and outlines to ensure safety requirements are being met.

1.6.15.2. Ensures mishap prevention programs and risk management concepts are

embedded in technical training and Professional Military Education.

1.6.15.3. Incorporates AFOSH program orientation into training programs for officer and

enlisted accessions and new civilian employees.

1.6.15.4. Develops and oversees safety training guidance for the development and

management of formal technical training (non-flying), OJT, ancillary and additional duty

training, automated training record and learning management systems, and Mission

Readiness Training.

1.6.16. Program Managers organize their offices, based on system acquisition program size

and complexity, to execute the system safety requirements elaborated by the DoD and Air

Force in DoDI 5000.02, AFI 63-101/20-101, and MIL-STD-882E. Acquisition Category

(ACAT) I Acquisition and Sustainment Program Managers integrate system safety into their