S.C. Department of Health and

Environmental Control

RETAIL FOOD ESTABLISHMENTS

PLANNING RESOURCE

Planning, Designing, Constructing and Equipping a Retail Food Establishment

March 2021

Table of Contents

Retail Food Establishments

Introduction ..............................................................................................................................1

Planning ....................................................................................................................................2

List of Foods to be Served (Menu) ....................................................................................................... 2

Food Handling Procedures and Processes .......................................................................................... 2

Design and Construction .........................................................................................................6

Location: Living and Sleeping Quarters ................................................................................................ 6

Plumbing .............................................................................................................................................. 6

Finishes (Indoor) ................................................................................................................................ 13

Finishes: Outdoor (Premises) ............................................................................................................. 17

Storage .............................................................................................................................................. 17

Pest Control ....................................................................................................................................... 19

Lighting .............................................................................................................................................. 20

Toilet Rooms, Employee Designated Areas ....................................................................................... 20

Equipment ............................................................................................................................... 22

Design and Construction .................................................................................................................... 22

Installation .......................................................................................................................................... 23

Protection for Foods on Display ......................................................................................................... 28

Warewashing Equipment ................................................................................................................... 30

Sinks .................................................................................................................................................. 32

Refrigeration ...................................................................................................................................... 34

Additional Retail Food Establishment Operations .............................................................. 37

Mobile Food Establishment .................................................................................................................. 37

Commissary ....................................................................................................................................... 37

Mobile Food Unit and Mobile Food Pushcart ...................................................................................... 38

Immediate Outdoor Cooking ................................................................................................................ 45

Design and Construction .................................................................................................................... 46

Barbecue Pit and Pit Cooking Room .................................................................................................... 49

Design and Construction .................................................................................................................... 49

Equipment .......................................................................................................................................... 51

General Guidance................................................................................................................... 52

1

Retail Food Establishments

Introduction

This Retail Food Establishment Planning Resource is intended to aid the owner, equipment dealers,

architects, engineers, consultants and others in the food industry with good manufacturing practices for

planning, constructing and equipping a retail food establishment to meet Regulation 61-25 requirements.

The goal of this guide is to promote uniform design and construction of retail food establishments that are

conducive to safe food handling. Properly designed and equipped retail food establishments promote good

cleaning and maintenance practices. While all types of equipment and conditions are not covered, the

fundamental concepts conveyed may be applied in all installations.

For minimum requirements please refer to South Carolina Department of Health and Environmental Control,

Regulation 61-25, Retail Food Establishments. Minimum requirements may not ensure the best possible

conditions for your facility.

This planning resource designed is to assist in the development of retail food establishments;

it is not an official part of Regulation 61-25.

The submission of plans and specifications may be required by other agencies depending upon the type of

facility being constructed, remodeled or renovated. It is recommended that the Fire, Mechanical, Plumbing

and Building Code officials are contacted regarding local requirements related to the retail food

establishment.

2

Planning

List of Foods to be Served (Menu)

Having an idea of the types of foods that are to be prepared and served will help in determining the types of

equipment needed. Identifying the main ingredients used to prepare each food will also help determine the

amount of space needed in the retail food establishment for storage and preparation.

Food Handling Procedures and Processes

Once the types of foods to be prepared and served are determined, the next step is to decide how each food

item will be handled to include preparation, storage, cooking, refrigerating, displaying, etc.

Descriptions, including specific areas of the food service establishment where foods are handled, will provide

a guide to planning the layout of food equipment for an effective workflow. It is also easier to determine the

types and quantities of food equipment needed when the processes used to prepare foods are known.

Following are workspaces that may be used in laying out handling procedures and processes needed for

foods prepared in the retail food establishment. Description of the process from receiving to ready-to-eat

should include:

•

How the food will arrive (frozen, fresh, packaged, etc.).

•

Where the food will be stored (cooler, freezer, dry storage).

•

Where the food will be handled (prep table, sink, counter, etc.).

•

How the food will be handled (washed, cut, marinated, breaded, cooked, etc.).

•

When food will be handled (time of day and frequency/day).

Ready-to-Eat Food Handling

Examples: salads, cold sandwiches, raw oysters, raw clams, cut fruit, etc.

Poultry Handling

3

Meat Handling

Seafood Handling

_

Sushi Preparation

Produce Handling

Dry Storage

A retail food establishment whose operation involves a special food process or procedure such as smoking,

curing, sushi rice, reduced oxygen packaging (ROP), sous vide, or cook/chill must submit in writing a request

for modification or waiver to the Department for review and approval.

Anticipated Volume of Food

Estimating the number of meals to be served/sold will help with determining the types and quantities of

cooking and refrigeration equipment needed and, the size of the dry storage area and/or frequency of supply

deliveries needed. It will also help in determining the size of the food preparation area(s) needed.

4

Sections below are provided as workspaces for thawing, cooling and reheating procedures.

Reheating for Hot Holding

Identify time/temperature control for safety (TCS) foods reheated to at least 165

o

F (74

o

C) within 2 hours.

Ready-to-eat (RTE) commercially processed foods may be heated to at least 135

o

F (57

o

C).

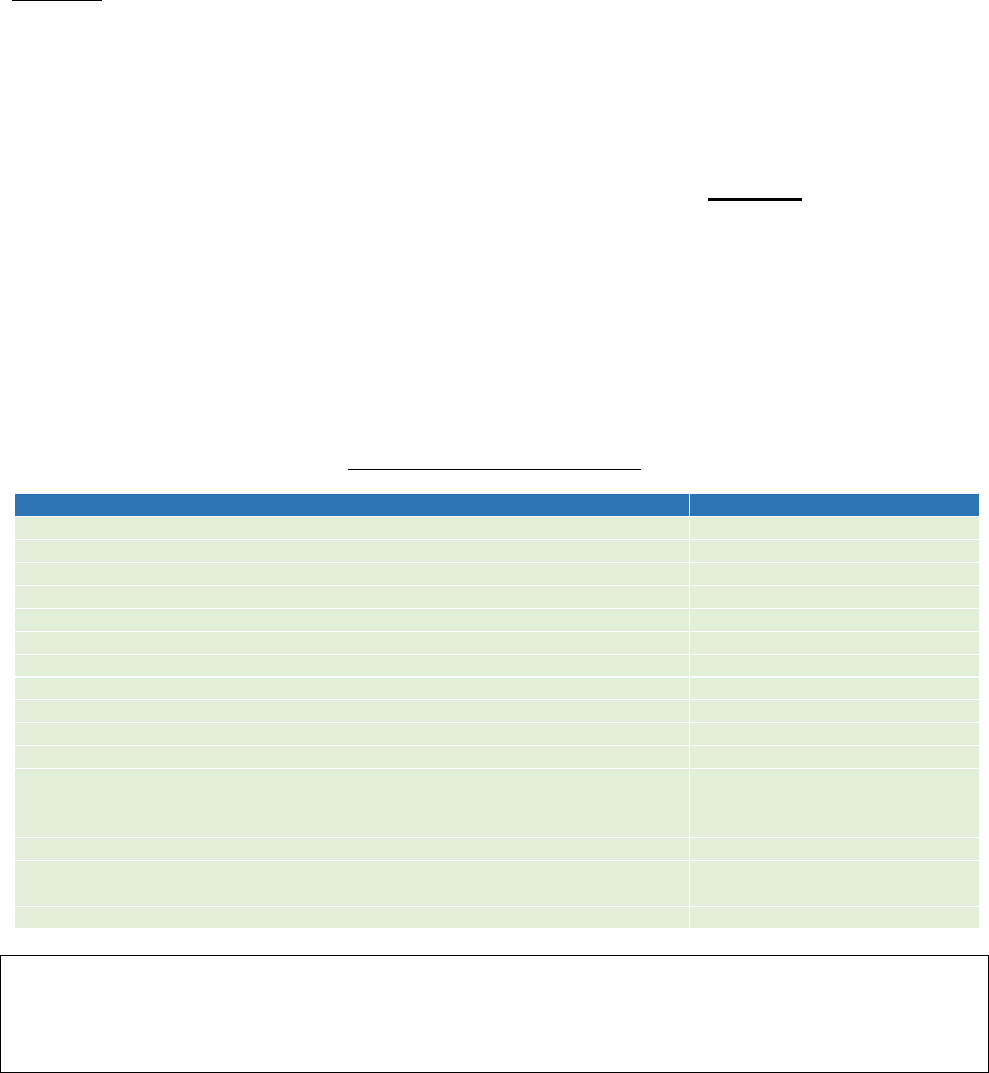

Food Item

Method of Reheating

RTE?

Yes No

Yes No

Yes No

Yes No

Thawing Process

Check appropriate boxes to indicate how food in each category will be thawed.

Cooling Process

Check appropriate boxes (TCS) foods are to be cooled to 70

o

F (21

o

C) within 2 hours and to 41

o

F (5

o

C)

within another 4 hours.

Meat

Seafood

Poultry

Other

(describe food type)

Shallow Pans in

Refrigeration

Ice baths

Rapid Chill

Other Method

5

Possible Food Process Step Needs

No Cook Step

X

X

X

X

X

X

Cook and Serve

X

X

X

X

X

X

X

Complex Processes

X

X

X

X

X

X

X

X

X

Receive

Store

Prepare

Cook

Cool

Reheat

Thawing

Hold

Service

Anticipated Equipment,

Utensil, Supply Needs

Thermometer

●

●

●

●

●

●

●

Dry Storage

●

Refrigerated Storage (Walk-in)

●

●

●

●

Frozen Storage ** (Walk-in)

●

●

Tables (Prep)

●

●

Cutting Board(s)

●

●

Utensils

●

●

●

●

Sink (Prep)

●

●

Coolers (Prep, Reach-in, etc.) *

●

●

●

●

●

Freezers **

●

●

●

●

Fryer

●

●

Oven

●

●

●

Charbroiler

●

●

Griddle

●

●

Cook Top/Burner

●

●

●

Ice Bath

●

Blast Chiller

●

Pans (Shallow)

●

●

●

●

Ice Paddle

●

Cold Holding/Service

●

●

Hot Holding/Service

ᴓ

●

Food Warmer

ᴓ

Microwave

●

●

●

Other:

Other:

* Preparation coolers (including low boys) are not designed for long-term storage. Reach-in coolers (and

similar equipment) are not designed for quick chilling of foods.

** Frozen storage units and freezers can promote cooling of foods but are not designed for quick chilling

of foods.

ᴓ Would not apply to “No Cook Step”.

6

Design and Construction

Location: Living and Sleeping Quarters

When the location of the retail food establishment is being considered, the following areas may not be used

to conduct retail food establishment operations:

•

A private home kitchen.

•

A room used or directly opening into a room used as living or sleeping quarters.

On premises living and sleeping quarters provided for lodging registration clerks or resident managers must

be separated from rooms and areas used for retail food establishment operations.

Plumbing

Drinking Water Supply

When constructing a retail food establishment or considering an existing structure, it is important to ensure

that the drinking water supply at the site is from an approved source that is:

•

A public water system of a city, town or other municipality.

•

A public water system (e.g. well) constructed for use by the retail food establishment.

•

Of sufficient capacity to meet peak water demands.

The city, town or other municipality, where the retail food establishment will be located should be contacted

to determine availability and other information on the public water system.

For information and requirements on a public water system, such as a well, constructed for use by the retail

food establishment, contact the local Environmental Affairs (EA) office for the Bureau of Water.

Backflow Prevention (Water)

To protect the drinking water supply from contamination by questionable water, chemicals or other source of

pollution, a method of backflow prevention must be provided at each point of use at the retail food

establishment. It is important that the backflow prevention method or device chosen meets the protection

needs at each point of use.

Air Gap

An air gap is a non-mechanical means of backflow prevention. It is a clear vertical separation between the

drinking water supply inlet and the flood level rim of the plumbing fixture.

NOTE:

The main backflow prevention device that may be required by the drinking water supplier protects the main

water supply only. In other words, it protects others from potential contamination that may occur inside your

facility. It does not provide protection from possible contamination within your facility.

7

Backflow Prevention Devices

An air gap between the drinking water supply inlet and

the flood level rim of the plumbing fixture, equipment

or non-food equipment must be at least twice (2x) the

diameter (D) of the water supply inlet and may not be

less than 1 inch (25mm).

It is recommended that the water supply inlet is rigidly

mounted to ensure the appropriate air gap is

maintained. A hose that extends below the flood level

rim of the plumbing fixture or reduces the minimum

required air gap distance should not be installed on

the water supply inlet.

An air gap may not be suitable for all applications.

Backflow prevention devices must meet American Society of Sanitary Engineering (ASSE) standards

specified for the application. When installed the device must meet the specific application and type of

device, and be easily accessible for inspection and servicing.

Although some backflow prevention devices may look similar on the outside, inside components determine

whether the device is designed for continuous or non-continuous pressure applications.

Following are examples of some commonly used backflow prevention devices in retail food establishments.

The descriptions are a general summary of how the devices work. For additional information on the

performance and installation of any of the devices, a plumber should be consulted.

Atmospheric Vacuum Breaker (AVB)

An atmospheric vacuum breaker (dome shaped) is not designed for

constant pressure. If subjected to long periods of continuous pressure, the

device may malfunction.

The AVB must be installed downstream of the

shutoff valve and at least 6 inches above the

highest outlet and/or overflow rim of the potential

source of contamination. When an AVB is

installed for a disposal or similar equipment, it

should extend through the backsplash of the

drainboard or soiled dish table.

Because the AVB is not designed for continuous pressure:

•

Valves should not be installed downstream of the AVB.

•

If used, the spray nozzle should be removed from the hose after each use so that the AVB cannot be

left under continuous pressure.

•

A hose equipped with a spray nozzle that is to remain connected must be turned off at the faucet and

the hose drained (bled) after each use.

NOTE:

A simple untested check valve is not very reliable and is not considered an acceptable method of backflow

prevention.

8

Examples of equipment where atmospheric vacuum breakers are often installed:

•

Mop sink spigots.

•

Mechanical warewashers.

•

Disposals.

•

Chemical dispensers.

•

Garbage can washers (usually installed in the drain of mop sinks or can wash basins).

Hose Bibb Vacuum Breaker

A hose bibb vacuum breaker is another type of

atmospheric vacuum breaker. It is usually installed at

the hose bib of a mop sink, can wash or other location

where a hose may be attached. Because a hose bib

vacuum breaker is not designed for continuous

pressure, a pressure spray nozzle should not remain

attached at the end of a hose when not in use.

Pressure Vacuum Breaker (PVB)

The pressure vacuum breaker looks almost like the AVB in that it

also has a dome shaped top. However, a pressure vacuum

breaker is designed for use in a continuous pressure application. It

is also equipped with test cocks that allow the device to be

performance tested.

The PVB must be installed at least 12 inches above the highest

outlet and/or overflow rim of the potential source of

contamination.

Pressure vacuum breakers are often installed on hose reel assemblies.

9

Dual-Check Valve Backflow Preventer

The dual-check valve backflow preventer is designed for continuous pressure applications. It operates

efficiently when installed vertically or horizontally.

Examples of equipment where dual-check valve backflow preventers are often installed:

•

Mop sink spigots (Used where a spray nozzle is attached at the end of a hose).

•

Water connections to food service equipment (e.g. steamers, combi-therm ovens, rack ovens,

beverage dispensers, coffee brewers, specialty coffee makers, tea brewers, ice machines, rotisserie

ovens, water chillers).

•

Submerged water inlets on food service equipment (e.g. pasta cookers, rethermalizers, woks,

scrapping troughs, steam tables).

•

Waste pulpers (drinking water supply line).

•

Disposals (drinking water supply line).

•

Chemical dispensers.

•

Hose reel assemblies.

Dual-Check Valve Backflow Preventer with Intermediate Atmospheric Vent

The dual-check valve backflow preventer with intermediate atmospheric vent is designed for continuous

pressure applications. If a backpressure event should occur and if the second check valve is unable to close

tightly, leakage will drain through the vent port.

The dual-check valve backflow preventer with intermediate atmospheric vent is often installed at a

carbonator. For additional installation information when this device is used at a carbonator, see R.61-25, 5-

203.15.

NOTE:

Installing two (2) hose bib vacuum breakers in-line is not equivalent to a dual-check valve backflow preventer

and does not create a continuous pressure device.

10

Sewage Disposal

When constructing a retail food establishment or considering an existing structure, it is important to ensure

that liquid waste containing animal or vegetable matter (sewage), that may also include chemicals, is

disposed through one of the following approved facilities:

•

A public sewage treatment plant.

•

An individual sewage disposal system.

The city, town, other municipality or individual sewer purveyor that provides the public sewage system,

where the retail food establishment will be located, should be contacted for availability and other information

on the sewage disposal system.

For information and requirements on an individual sewage disposal system, such as a septic tank,

constructed for use by the retail food establishment, contact the local Environmental Affairs (EA) office for

Onsite Wastewater.

Backflow Prevention (Sewage)

A direct connection may not exist between the sewerage system and any drains connected to equipment in

which food, portable equipment or utensils are placed.

Drains

Indirect drainage may be accomplished by using floor sinks, hub drains, floor drains or floor troughs. The

drain(s) chosen should be sized and positioned to effectively prevent or minimize liquid waste from

splashing or running across the floor. For assistance in determining the type of drain(s) needed, a plumber

should be consulted.

Drains for food equipment should be positioned so that they are accessible for maintenance.

Floor drains should be provided when floors are to be water-flushed for cleaning and/or where clean-in-place

equipment is to be installed.

NOTES:

o

Liquid waste drain lines must not pass through an ice machine or ice storage bin.

o

A warewashing or food preparation (culinary) sink may have a direct connection, unless otherwise

required by law. A mechanical warewasher may have a direct connection between its waste outlet

and a floor drain when the warewasher is located within 5 feet of a trapped floor drain and the

warewasher outlet is connected to the inlet side of a properly vented floor drain trap.

11

Floor drains, floor sinks and troughs should be installed so that they are even (flush) with the finished floor.

A raised drain may result in the pooling of water or the collection of debris around the rim of the drain. When

the floor slopes to the drain the transition should be consistent and smooth. An uneven transition may result

in water and food collecting in crevices between the floor and the drain.

Examples of equipment where indirect drainage is used:

•

Steam tables (hot wells), cold wells (ice).

•

Steamers, rotisserie ovens, pasta cookers,

rethermalizers.

•

Rack ovens, combi-therm ovens, wok stoves,

proofers.

•

Beverage dispensers, ice machines, ice bins,

dipper wells, water chillers.

•

Mechanical warewashers.

Condensate from walk-in refrigeration units should be drained using one of the following methods:

•

Indirectly drained to a floor drain or hub drain that is accessible for cleaning and maintenance.

•

Drained to an exterior dry well.

•

Drained using another disposal method that does not create a nuisance.

Grease Trap/Grease Interceptor

The purpose of a grease trap or a grease interceptor is to reduce the amount of fat, oil and grease (FOG)

that enters a sewage disposal system. Whether a grease trap or grease interceptor is required is determined

by the city, town, other municipality or individual sewer purveyor that provides services to the retail food

establishment. The service provider should be contacted for grease trap/grease interceptor sizing

information and other requirements.

For information on an individual sewage disposal system and grease traps or grease interceptors, refer to

South Carolina Department of Health & Environmental Control, Regulation 61-56, Onsite Wastewater

Systems.

Grease Trap

When installed, a grease trap must be located outside so that it is easily accessible for cleaning and

maintenance. However, when the building is the property line, a grease trap may be installed inside the

retail food establishment provided it meets the following installation requirements.

A grease trap located inside a retail food establishment must not be installed in:

•

Food preparation, dispensing or storage areas.

•

Food equipment storage areas.

•

Equipment and utensil washing areas.

•

Single-service articles storage areas.

Location of a grease trap inside must not result in servicing hoses and pumps having to run through the

following areas to reach it:

•

Food preparation, dispensing or storage areas.

•

Food equipment storage areas.

•

Equipment and utensil washing areas.

•

Single-service articles storage areas.

12

Grease Interceptor

When installed, a grease interceptor:

•

May be installed in:

o

Food preparation areas.

o

Food storage areas.

o

Equipment and utensil washing areas.

•

When installed on the floor:

o

Must have a minimum unobstructed

access clearance of 24 inches above

the interceptor.

o

Must be spaced at least 6 inches away

from walls, stationary equipment or

other adjacent surfaces.

•

When recessed to floor level:

o

Must have a minimum unobstructed

access clearance of 24 inches

above the interceptor. Clearance

allows removal of baffles and

access for cleaning.

o

Equipment must not be placed on top

of the interceptor.

Exception: Floor-mounted

equipment that is mobile or

portable may be located on the

unit.

•

Grease interceptors are to be serviced manually.

Utility Lines

Utility service lines and pipes should not be unnecessarily exposed. As much as possible utility service lines

and pipes should be installed between the roof and the ceiling, behind walls and underneath the finished

floor.

When installed, exposed utility service lines and pipes must not obstruct or prevent cleaning of floors, walls

and ceilings.

Exposed horizontal utility service lines and pipes may not be installed on the floor.

Hot Water

Hot water supply must be sufficient to meet peak demands of the retail food establishment.

Handwashing - At each sink, water of at least 100

o

F (38

o

C) must be provided.

NOTE (for indoor installation):

Some grease traps may be available with a suction line that runs from the grease trap to an outside capped

port. When a grease trap must be installed inside a facility, this system design eliminates the need for hoses

to run through the retail food establishment to service the grease trap. A system designer may be able to

evaluate if this type of installation is suitable for your retail food establishment.

13

Manual warewashing - The wash solution in the sink must be maintained at a temperature of at least 110

o

F

(43

o

C) or the temperature specified on the cleaning agent manufacturer’s label. When hot water sanitization

is used at a manual warewashing sink, the sanitizing compartment must be provided with a system that will

maintain a temperature of at least 171

o

F (77

o

C).

Mechanical warewashing machines (including glass washers) - Hot water provided must meet minimum

temperature(s) specified on the warewashing machine’s data plate. Washing and sanitizing temperatures

specified on the data plate usually range from 120

o

F (49

o

C) to180

o

F (82

o

C). The wash temperature for a

chemical sanitizing mechanical warewasher may not be less than 120

o

F (49

o

C).

Hot water sanitizing temperatures entering the mechanical warewasher’s manifold may not exceed 194

o

F

(90

o

C). A booster heater may be needed to ensure the minimum hot water temperature specified on the data

plate is reached for the final rinse on a hot water sanitizing mechanical warewasher.

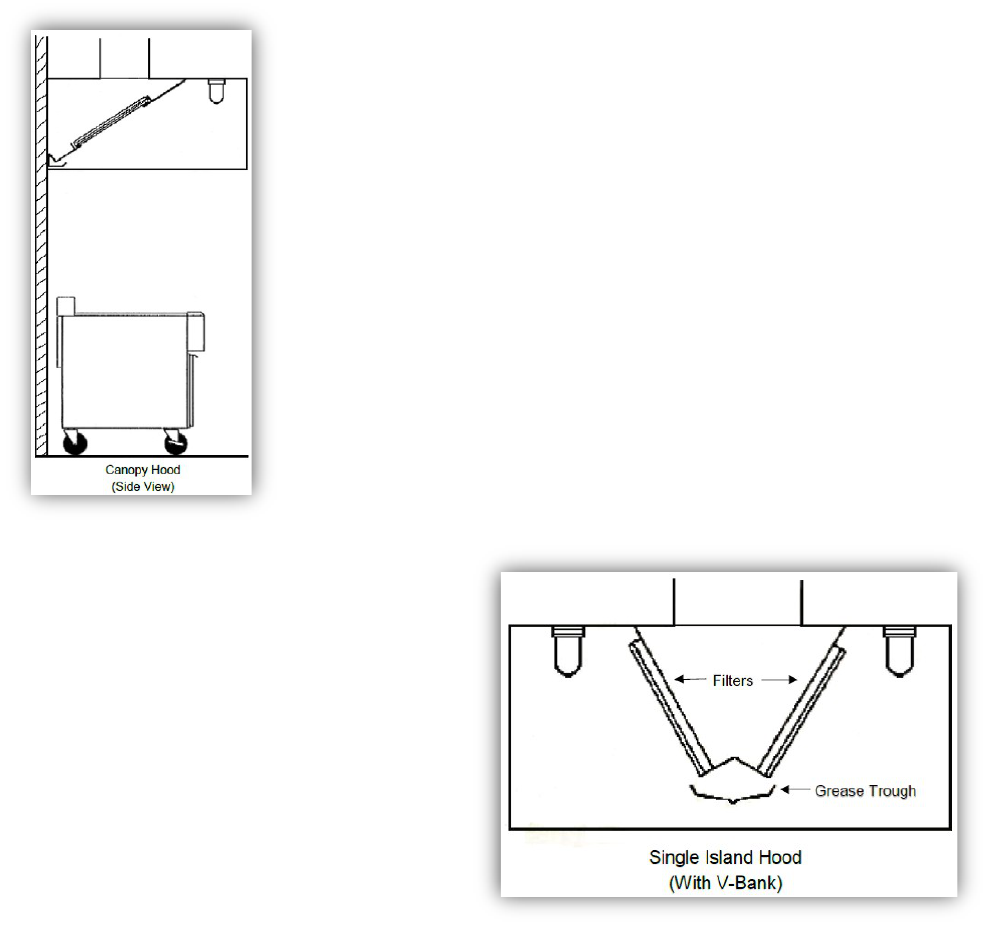

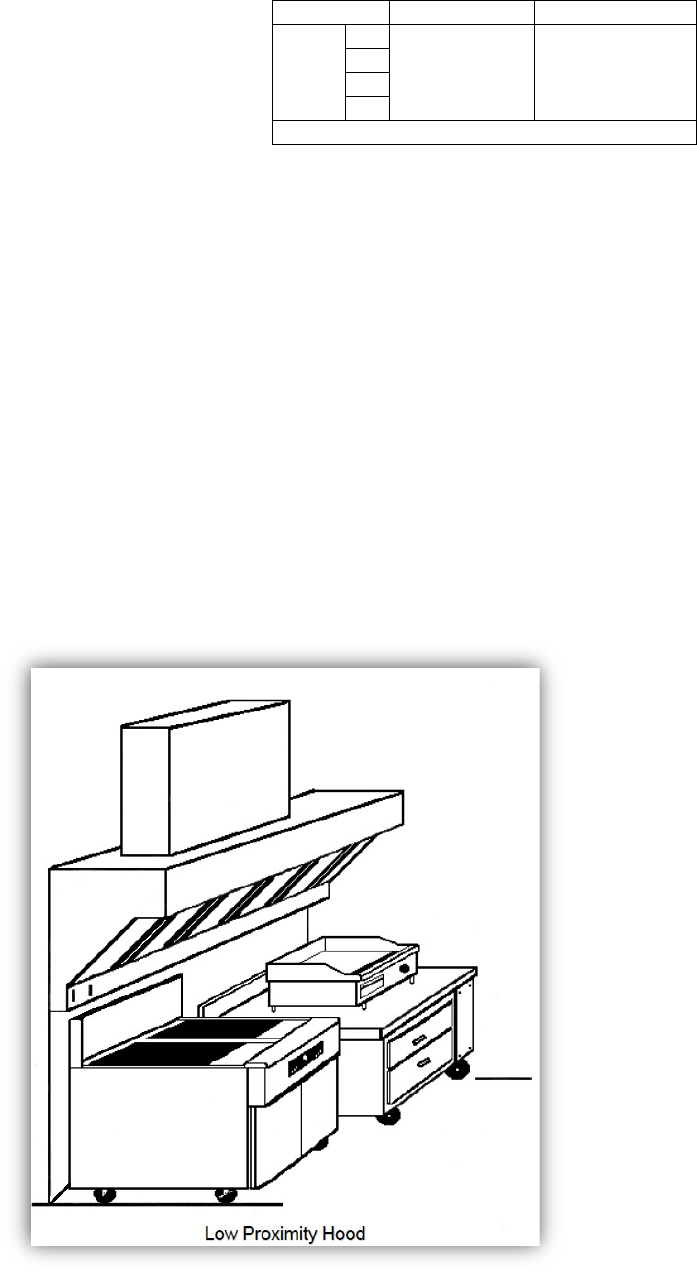

Ventilation

When necessary, ventilation of sufficient capacity should be provided to keep the facility free of excessive

heat, steam, condensation, vapors, obnoxious odors, smoke and fumes.

When ventilation hood systems are installed in food preparation and warewashing areas, they should be

designed to prevent grease or condensation from dripping or draining onto food, equipment or utensils.

Finishes (Indoor)

Indoor material finishes for floors, walls and ceilings must meet all requirements of Regulation 61-25, Retail

Food Establishments; however, some construction materials require special considerations.

When deciding on the materials and finishes to install, consideration should be given to the amount of

physical effort that may be required to clean and maintain the finish.

Finishes should be installed or applied according to manufacturer’s instructions.

Floors

Exposed concrete floors must be effectively sealed so that the surface is nonabsorbent.

In mechanical warewashing machine areas, floors such as terrazzo, quarry tile, epoxy, and sealed concrete

are recommended due to proven durability. Vinyl composition tile (VCT) is not recommended underneath a

mechanical warewashing machine because the moisture and heat generated by the equipment may affect

the durability of the tile. High heat equipment such as fryers may also affect the durability of VCT.

There are ceramic tiles available that imitate natural stones such as slate and limestone. Like natural

stones, some of the ceramic tiles are porous and absorbent. When installed in food preparation areas,

warewashing areas, storage areas, other areas that support food service or toilet rooms, the tile should be

sealed so that the surface is nonabsorbent and easily cleanable.

Porous and absorbent natural stone floors installed in food service, warewashing or storage areas should be

sealed so that the surface is smooth, easily cleanable and nonabsorbent. In toilet rooms, floors must be

cleanable and nonabsorbent. Some natural stones are soft and may not be durable when installed

underneath heavy food equipment.

Rubber flooring is a durable material for food service operations provided the right flooring is chosen for the

application. For example, rubber flooring designed for some sports surfaces tend to be light and spongy to

14

absorb impact. Impact absorbing sports flooring is not designed to support the heavy weight or withstand the

heat of some food service equipment.

Vinyl sheet flooring (commercial) installed using weld rods to heat-weld seams, create a durable, unbroken,

one-piece finish. Many textured designs provide slip resistance while having the ability to be easily cleaned

and maintained.

Sealed wood flooring is acceptable when maintained in good repair. Polyurethane, urethane, epoxy or

similar coatings may be applied to wood flooring to meet Chapter 6 criteria.

Anti-slip floor coverings, coatings or treatments may be used on floors. However, the application of abrasive,

anti-slip coatings or treatments should be limited to traffic areas.

When provided, to effectively capture liquids and facilitate cleaning, floor drains and floor sinks should be

installed so that they are flush (even) with the floor surface.

Cove Base

Junctures between the floor and walls must

be coved. The cove base helps to make

cleaning of the floor near walls easier and

provides protection to walls at junctures. It is

recommended that the cove has a minimum

height of 4 inches and a radius of at least 1/4

inch.

The cove base should be smooth, durable, non-absorbent and easily cleanable. When water flush cleaning

is used in a retail food establishment the transition between the flooring and the cove base should be smooth

and cove junctures must be sealed.

Rubber and vinyl cove base, usually supplied in rolls or coils, that are often used in offices, school

classrooms and other similar facilities are not recommended when floors are to be water flushed.

15

Walls

The area subject to moisture is considered the highest level that may be reached by splash or spray. The

level of splash or spray is generally considered 4 to 5 feet above the finished floor. However, when large

pieces of equipment such as mechanical warewashers or floor-mounted mixers are installed, the area of

splash or spray may be as high as 8 feet above the finished floor.

Rooms used only for the storage of unopened packages or containers are exempt from wall finish

requirements.

Brick and concrete block walls (CMU – Concrete Masonry Unit) in food preparation areas, equipment and

utensil washing areas, and garbage storage rooms must have smooth, nonabsorbent and easily cleanable

surfaces in areas subject to moisture.

Walls constructed of masonry products should be skim coated or provided with sufficient block filler to

provide a smooth surface prior to applying a washable paint. The degree of smoothness desired on the filled

masonry product should be thought of as “smooth as sheetrock.”

Block (Concrete Masonry Unit - CMU)

The following is offered as a solution to assist in meeting the minimum cleanability standards of block walls.

It is recommended that a high solids block filler (greater than 50%) is applied to the block.

The following factors may affect the number of applications needed to render the block face smooth (like

sheetrock) prior to painting:

•

Density of the CMU – Less dense CMU tend to have more voids.

•

Surface of CMU – CMU may have a smooth or textured surface.

•

Method(s) used to apply block filler – e.g. trowel, paint sprayer, brush or roller.

Brick

When brick is chosen for “atmosphere” in areas where retail food operations occur, a clear coat finish appropriate

for brick may be used; provided sufficient coats are applied to render a smooth, easily cleanable, nonabsorbent

surface up to the highest level that may be reached by splash or spray.

Ovens with a brick finish should also have smooth, nonabsorbent and cleanable surfaces.

Wall Panels

Fiberglass Reinforced Polyester (FRP) panels, plastic laminated panels and similar wall panel materials

should be installed using the appropriate molding or other means that will provide smooth, cleanable

junctures.

Ceilings

Suspended ceilings with acoustical tile or other similar lay-in products may be installed in all areas, provided

the lay-in products are easily removable for replacement or cleaning.

Rooms used only for the storage of unopened packages or containers are exempt from ceiling finish

requirements.

16

SUGGESTIONS:

To test a material under consideration in areas where finishes should be smooth, nonabsorbent and easily

cleanable, spread mustard or ketchup on a sample and allow it to set for a least 30 minutes. Wipe and

review the surface keeping in mind the following:

•

Was a stain left on the surface?

•

Did the ketchup or mustard collect in grooves, crevices or divots?

•

Were chemicals and heavy scrubbing needed to clean the surface?

To test a material under consideration in areas where finishes should be nonabsorbent, place a few drops of

water on a sample. Does the water bead on top of the surface or does the water soak into the surface?

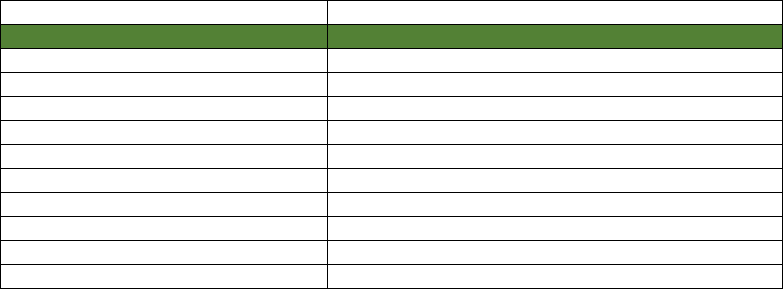

Below is a workspace that may be used to chart the finishes to be used in each area.

Location

Floors

Walls

Ceilings

Food Preparation (Kitchen)

Display Cooking/Preparation

Warewashing

Dry Storage

Walk-in Coolers/Freezers

Employee Toilet Room(s)

Customer Toilet Room(s)

Other:

Other:

Other:

Other:

Other:

Below are some commonly used abbreviations that may be helpful in using the workspace above.

ACT – Acoustical Ceiling Tile

GWB or Gyp. – Gypsum Wall Board

RF – Resinous Flooring

Conc. – Concrete

Mfr. or Mfg. – Manufacturer

SS – Stainless Steel

CMU – Concrete Masonry Unit (Block)

PT – Porcelain Tile

VCT – Vinyl Composition Tile

CT – Ceramic Tile

pnt – Paint

VLT – Vinyl Lay-in Ceiling Tile

Exp. – Exposed

QT – Quarry Tile

VWC – Vinyl Wallcovering

FRP – Fiberglass Reinforced Panels

17

Finishes: Outdoor (Premises)

Outdoor walking and driving surfaces of the premises must be concrete, asphalt, gravel or other similar

material. These types of materials minimize dusty and muddy conditions inside and outside the facility, as

well as facilitate surface maintenance. The surface must also be graded to drain to prevent standing water.

Outdoor refuse, recyclables and returnables surfaces on the premises must be constructed of smooth,

durable and nonabsorbent materials such as concrete or asphalt. The surfaces must also be graded to drain

for the sanitary disposal of liquid waste (sewage) generated from cleaning the surfaces and equipment

located in these areas. An enclosure, if provided for outdoor refuse, recyclables and returnables must be

constructed of durable and cleanable materials.

Servicing area for a mobile food unit or mobile food pushcart must be constructed of smooth materials, such

as concrete or asphalt, and must be properly drained. The servicing area must also be provided with

overhead protection unless the area is used only for the loading of drinking water or the discharge of sewage

and other liquid waste through a closed system of hoses.

Storage

The amount of storage equipment and area(s) needed may depend upon several of the following factors:

•

Foods to be served (menu).

•

Number of meals served between deliveries.

•

Amount and type of single-service items to be stored.

•

Amount of TCS foods to be served/stored.

•

Amount of non-TCS foods and ingredients to be served/stored.

•

Amount and type of equipment and utensils to be stored.

•

Frequency of deliveries.

Food, food equipment and utensils may not be stored in the following locations

:

•

Locker rooms, toilet rooms, garbage rooms or mechanical rooms.

•

Underneath unshielded sewer lines, waters lines, leaking fire sprinkler

heads, lines on which water has condensed or open stairwells.

Laundered linens and single-service and single-use articles that are packaged or are stored in a cabinet may

be stored in a locker room. However, these items may not be stored in the following locations:

•

Toilet rooms, garbage rooms or mechanical rooms.

•

Underneath unshielded sewer lines, waters lines, leaking fire sprinkler heads, lines on which water

has condensed or open stairwells.

Equipment

Shelving, dollies, racks, etc. should be finished so that they are nonabsorbent, corrosion-resistant, durable

and smooth. Peg boards are not recommended for use in food preparation and operations areas.

NOTE:

Equipment and supplies (e.g. lawn mowers, weed trimmers, blowers, gasoline containers, pesticides and

motor oils) used to maintain the exterior of the retail food establishment that are stored on the premises,

must be stored to prevent contamination of food, food equipment, utensils and single service and single-use

articles. Whenever possible a separate room or area should be provided for these items.

18

The lowest shelf must be at least 6 inches above the floor. This allows access for cleaning the floor

underneath as well as provides some protection to food and equipment from splash during cleanup and from

spills that may occur. It also discourages pest harborage areas underneath shelving.

When storing bulk foods such as flour, sugar, rice, grits and similar foods, food containers with tight-fitting

covers should be used. Bulk food containers installed on casters or mounted on dollies allow the containers

to be easily moved for cleaning.

Pallets should not be used for permanent storage and should be removed once they are emptied of the

delivered content. Because of their design, pallets do not allow easy cleaning of the floor underneath and

can become ideal pest harborage areas.

Milk crates should not be used as shelving. Once the delivered content of the milk crates has been emptied,

they should be removed.

Refrigeration storage needs for the retail food establishment may include various reach-in coolers, freezers

and walk-in refrigeration units. Reviewing the foods to be served for ingredients that require refrigeration, as

well as the frequency of deliveries of TCS foods, should help in determining types and quantities of

refrigeration needed. For additional guidance on refrigeration see Retail Food Establishments,

Equipment, Refrigeration.

Area(s)

The dry storage area or room should be adjacent to the food preparation area and convenient to receiving.

STORAGE PLANNING EXAMPLE:

Restaurant B plans to cook BBQ on a 5-ft. grill for buffet style dining. In addition, a range/oven, convection

oven, steamer and a fryer will be installed to prepare vegetables, rice, mashed potatoes, breads, fries,

chicken, fish and desserts. A small closet and two wall shelves will provide storage for single-service

articles (to-go containers, forks, cups, napkins, etc.) and shelf-stable food ingredients. Because of limited

space there is only room for a 2-door under-counter cooler; no walk-in cooler or freezer is installed.

In planning the retail food establishment, answering the following questions may have helped the owner

better evaluate the facility’s storage needs:

•

What TCS foods and ingredients require refrigeration upon delivery?

o

Which of those delivered TCS foods and ingredients will be:

Stored in a cooler(s)?

Stored in a freezer(s)?

o

What are the delivery quantities of each TCS food or ingredient?

•

How many days are between deliveries of TCS foods and ingredients?

•

Are there TCS foods that are to be prepared and stored under refrigeration for service at a later

date? In what quantities?

•

How many meals will be served between deliveries?

•

Will refrigeration space be needed for leftovers? How much?

•

How many to-go meals will the facility serve between deliveries?

•

What types and quantities of single service articles (cups, plates, utensils, etc.) will be stored for to-

go meals?

•

What non-TCS foods and ingredients require storage space?

CFP Plan Review for Food Establishments manual provides resources for sizing storage areas and refrigeration.

19

Pest Control

A retail food establishment must be designed and constructed to restrict the entrance of insects, rodents and

other pests.

•

Holes and other gaps along floors, walls and ceilings must be sealed.

•

Openings around pipes, conduit or wiring must be sealed.

•

Solid doors opening to the outside must be tight-fitting. Gaps may be closed by installing door

sweeps and/or weather-stripping made of rodent proof materials.

•

Solid doors opening to the outside should be self-closing or provided with interlocked air curtains (fly

fans).

•

Windows must be tight-fitting. Gaps may be closed by installing weather-stripping.

•

Service windows must be self-closing or provided with interlocked air curtains (fly fans).

•

When installed, screen doors should be tight-fitting and self-closing.

•

When installed, screening at service windows should be tight-fitting and self-closing. Service

windows, whether screened or solid, that are not self-closing should be provided with interlocked air

curtains (fly fans).

•

Screening material must not be less than 16 mesh to the inch.

Pest Control Devices

If used, traps, electrocutors and automatic dispensers should be installed per manufacturer’s instructions.

When choosing the type and location of devices, the following criteria should be considered.

Light Traps and Low Voltage Fly Traps

Light traps and low voltage fly traps should not be installed on or above food, food contact surfaces, clean

equipment, utensils, linens, unwrapped single-service articles and single-use articles.

Insect Electrocutors

Electrocutors should be installed no closer than 5 feet from exposed food, food contact surfaces or

clean equipment, utensils, linens, single-service and single-use articles.

Only wall mounted units should be used.

Automatic Dispensers

Automatic metered devices used to dispense pyrethrin sprays should be installed and operated per the

pesticide’s EPA (Environmental Protection Agency) registered label. If not specified, the devices should not

be installed over or within 8 feet of exposed food, utensils, equipment, or food handling or preparation areas.

NOTE:

If the retail food establishment opens into a larger, completely enclosed structure such as a mall, airport,

office building or arena, where outer openings of the larger structure are protected against insects and

rodents, installation of solid, tight-fitting doors or air curtains (fly fans) may not apply.

20

Lighting

Intensity

At least 50 foot-candles (540 lux) must be provided at surfaces where:

•

Employees will be working (chopping, slicing, grinding, mixing, cutting, cooking, etc.) with foods.

•

Employee safety is a factor.

At least 20 foot-candles (215 lux) must be provided:

•

At the surface of customer self-service buffet and salad bars.

•

Where fresh produce or packaged foods are sold or offered for consumption.

•

At the entrance to reach-in and under-counter coolers and similar equipment.

•

At 30 inches above the floor in:

o

Areas used for handwashing, warewashing and equipment and utensil storage.

o

Toilet rooms.

At least 10 foot-candles (108 lux) of light measured at 30 inches above the floor provided in:

•

Walk-in refrigeration units.

•

Dry storage areas.

•

Other rooms and areas not specified above, during cleaning.

Protection

Light bulbs must be shielded, coated or shatter-resistant in areas where there is exposed food; clean

equipment, utensils and linens; or unwrapped single-service and single-use articles.

Protection may be achieved by using plastic shields, plastic sleeves with end caps or shatter-resistant bulbs.

Infrared or other heat lamps should be protected against breakage by a shield surrounding and extending

beyond the bulb so that only the face of the bulb is exposed.

Bulbs in areas used only for storing food in unopened packages are not required to be shatter resistant,

provided:

• Packages will not be affected by broken glass falling onto them, and

• They are capable of being cleaned of all glass debris.

Toilet Rooms, Employee Designated Areas

Toilet Rooms

Toilet rooms must be conveniently located and accessible to employees during all hours of operation. When

toilet rooms open directly into food operations areas, they must be completely enclosed and provided with

tight-fitting, self-closing doors. Handwashing sinks must be located inside or immediately adjacent to toilet

rooms.

The path to toilet rooms provided for customer use must not travel through food preparation, food storage or

warewashing areas.

21

Lockers

Lockers or other suitable facilities for the storage of employee personal items (e.g. sweaters, jackets, bags),

must be provided and located in a designated area or room where contamination of food, equipment,

utensils, linens, single-service articles and single-use articles cannot occur.

Examples of other suitable facilities are shelving, coat racks, hooks or cabinets.

Break and Dressing Areas

If employees are not allowed to take breaks in the dining area, a room or area designated for employee

breaks (for eating or drinking) must be provided. The room or area must be in a location that protects food,

equipment, utensils, linens, single-service and single use articles from contamination.

If employees will routinely change their clothes in the establishment, dressing rooms or areas must be

designated for that purpose.

22

Equipment

Design and Construction

All food service equipment, including any used equipment must meet NSF International (NSF – formerly

National Sanitation Foundation), Baking Industry Sanitation Standards Committee (BISSC), or other

authorized American National Standards Institute (ANSI) Commercial Food Equipment Standards sanitation

certification program recognized by the department, unless otherwise specified in R.61-25.

Food equipment used in the retail food establishment must bear the certification mark of the ANSI authorized

organization that tested and certified the equipment (e.g. NSF, UL, ETL, CSA, BISSC) to commercial food

equipment or baking industry standards.

Used equipment that is certified to ANSI/NSF or ANSI/BISSC standards may be acceptable, provided the

equipment has been properly maintained and has not been modified.

Some organizations, such as UL, ETL and CSA, also test and certify electrical and gas components attached

to equipment. Therefore, more than one certification mark may be affixed to an item of equipment. Different

mark designs are used by these organizations to help identify the type(s) of testing performed on the

equipment. Below are some examples of commercial food equipment and baking industry standards marks.

ANSI Accredited Certification Program

Sanitation Mark

NSF International (NSF)*

Underwriter’s Laboratories (UL)*

Intertek (ETL)*

CSA Group (CSA)*

Baking Industry Sanitation Standards Committee (BISSC)

* Mark may also include one of the following:

“Conforms to ANSI/NSF STD #” or “Certified to ANSI/NSF STD #.”

23

Food equipment used in the facility that are exempt from certification must be:

•

Made of materials that are corrosion resistant, smooth and nonabsorbent.

•

Designed and constructed to allow all parts that require cleaning to be easily accessed. The

equipment should also be designed to minimize places that could harbor insects, rodents and other

pests.

•

Designed to meet all other criteria that apply as outlined in 4-1 and 4-2 of Chapter 4.

It is recommended that shelves and racks are constructed of aluminum, stainless steel, plastic or epoxy/vinyl

coated metal. Wooden shelves and racks should be properly sealed.

Installation

This section provides guidance to help ensure effective food equipment installations that will allow adequate

and easy cleaning of equipment, and areas around and underneath the equipment.

Location

Equipment including ice machines and ice storage equipment may not be located under exposed or

unprotected sewer lines, open stairwells or other sources of contamination.

Ice machines with ice storage equipment should be installed inside the retail food establishment. This does

not apply to bagged ice merchandise freezers.

Floor-mounted Equipment

Casters

Whenever possible floor-mounted equipment should be

installed on casters. Casters make it easier to move

equipment for cleaning of surrounding surfaces and the

floor underneath; as well as allow easy access for

servicing of equipment. Equipment spacing requirements

for cleaning is reduced or eliminated when equipment is

installed on casters. Having equipment on casters also

allows maximum use of food service space.

Casters should be made of materials that are designed to withstand the

conditions in a retail food establishment and should also be sized for

the equipment served. For equipment that needs to remain stationary

during normal operations, at least two locking casters should be

installed.

Skids may be an acceptable alternative to casters when designed for the food service equipment served.

24

Utility service lines (gas, electrical, etc.) for food equipment on casters

should be flexible or equipped with easily accessible quick-disconnect

couplings. An equipment restraining cable may be used to limit

movement of food equipment and protect gas hoses and/or electrical

connections from damage or disconnection. The attached restraining

cable should be shorter than the flexible line but should be long enough to

allow enough space for cleaning. Local fire safety, plumbing and building

codes should be checked when considering the use of flexible service

lines and quick disconnect couplings.

Legs

Equipment installed directly on the floor, such as proofers, rack ovens and retarders, should be sealed

around the entire perimeter of the equipment. The sealant used should provide a water and pest-tight seal.

Ramps or kick plates, installed at roll-in proofers and similar equipment, that are easily removable for

cleaning should not be sealed to the floor.

Equipment installed on a masonry base reduces the total floor area that must

be cleaned. The masonry base should be at least 4 inches in height with a

cove of at least 3- inch radius at the juncture of the base and the floor.

Equipment should overhang the base at least 2 inches, but not more than the

height of the base. Overhang of equipment on the base prevents grease

and/or other liquids that may spill or run down the sides from running

underneath. The juncture between the base of the equipment and the

masonry base should be sealed to prevent pest harborage.

When equipment is installed on the floor or on a masonry base, enough

spacing from walls and/or other equipment for cleaning access must be

considered. See Spacing and Sealing in this section for additional guidance.

NOTE:

Furniture skids, movers and slides are designed to facilitate moving of home and office furniture.

Equipment installed on legs must provide at least 6 inches of clearance between the floor

and equipment.

If no part of the floor under the equipment is more than 6 inches from the cleaning

access point, the clearance space may be 4 inches.

NOTE:

Floor clearance space of 4 inches does not apply to shelving used to store food, linens, equipment,

utensils, single

-service articles and single-use articles.

Legs of food equipment should be made of materials that are smoo

th, durable,

nonabsorbent and easily cleanable. Legs should also be free of openings or

crevices that would allow pest harborage. For leveling of food equipment, legs

should be adjustable.

When floor

-mounted equipment is installed on legs, enough spacing from walls and

other equipment for cleaning access must be considered. See

Spacing and Sealing

in this section for additional guidance.

Other Fixed Equipment (not installed on legs)

25

Spacing and Sealing

Fixed equipment that cannot be easily moved should either be spaced to allow cleaning between and behind

the equipment or sealed to adjacent walls and other fixed equipment.

Spacing:

Equipment that is sealed to the floor or cannot otherwise be easily moved should be installed to provide

enough space for cleaning of the equipment and surrounding areas. The minimum spacing needed for

cleaning access may be affected by the depth and height of the equipment.

A fan that protrudes from the back of equipment, such as a convection oven or similar equipment, may affect

the minimum amount of spacing needed. Other obstructions to the access opening between and/or behind

equipment such as a chase or rigid utility connection may also result in the need for additional spacing.

Following is recommended guidance for minimum spacing of stationary floor mounted equipment:

•

Provided access is available from both ends of the equipment:

Total Length of Equipment (A) Minimum Space from Walls

and Other Stationary

Equipment (B)

4-feet or less

Over 4-feet but less than 8-feet

8-feet and over

6 inches

12 inches

18 inches

•

When fixed equipment having a total depth of 4 feet or less are installed side-by-side where there

are no wall barriers or other obstructions such as a chase or rigid utility connection, at least six

(6) inches of space should be provided between the equipment. This allows cleaning of the sides of

the equipment from the front and back access points.

NOTE:

The food equipment manufacturer’s installation instructions may also specify minimum spacing (usually 3” to

6”). This minimum spacing is to ensure the best performance of the equipment only. Fixed equipment may

need additional spacing beyond the manufacturer’s installation requirements to provide sufficient cleaning

access.

26

Equipment that is open underneath, such as a drainboard, dish table or open base table may be spaced

away from the wall (about 3” to 4”). This is due to the drainboard, dish table or immobile base table being

accessible underneath the countertop.

Sealing:

Equipment attached to walls, such as lavatories, preparation sinks,

warewashing sinks, dish tables, counters, cabinets or cooking equipment

must be effectively sealed to the wall to prevent splash, debris

accumulation and pest harborage.

When the space between the equipment (e.g. walk-in coolers and freezers,

retarders, proofers, large ovens) and the wall is too large for use of a

silicone sealant, metal or other approved flashing should be used. Some

installations may need a combination of flashing and silicone sealant.

Equipment (e.g. under-counter coolers and freezers, under-counter mechanical warewasher, back bar

refrigeration, food warmer) not installed on casters or skids, and located underneath a table, counter or

drainboard should be sealed to adjoining surfaces. It is recommended that the manufacture’s trim kit for the

equipment is used if one is available.

Equipment mounted on legs, such as prep tables and some equipment tables, which are placed against

walls but can be easily moved for cleaning do not have to be sealed to adjacent surfaces.

Counter-mounted Equipment

Size, weight, height and the use of rigid utility

connections should be considered when installing

food equipment on counters or tables. Below are

guidelines for installation.

Portable

Counter-mounted equipment is generally considered

portable if it is small and light enough to be easily

moved by one person.

Easily movable means that the

equipment can be lifted or slid across

a table or counter to allow cleaning

access underneath and behind the

equipment. Also, to be considered

portable, equipment may not have

fixed utility connections.

NOTE:

Any combination of bolts, screws, rivets, sealers or flashing that effectively closes the opening between the

equipment and the walls in a smooth and sanitary manner is acceptable.

27

Legs

Counter-mounted equipment elevated on legs should provide at least 4 inches of clearance between the

table and the equipment.

If the horizontal distance of the tabletop under the equipment is no more than 20 inches from the cleaning

access point, the clearance may be 3 inches.

If the horizontal distance of the tabletop under the equipment is no more than 3 inches from the cleaning

access point, the clearance may be 2 inches.

Fixed Equipment (not installed on legs)

Counter-mounted equipment not installed on legs and that are not portable should be sealed to the table or

counter. The sealant used should provide a water- and pest-tight seal.

Sealed

Equipment installed on shelving underneath a table or counter that is not portable should be sealed to

adjoining surfaces. If available, it is recommended that the manufacture’s trim kit for the equipment is used.

Aisle Spacing

This section is provided only as a guide.

Unobstructed and functional aisles and workspaces should be provided. Single-aisle width should be at

least 30 inches, but not less than what may be required by local building and fire codes. For a food

preparation area designed so that employees work back-to-back, a double-aisle width of at least 60 inches

is recommended.

In determining the width of aisles and workspaces the following should be considered:

•

Number of employees at the workstations during peak operations.

•

Type and layout of equipment in the workspace(s).

•

Clearance needed for effectively opening equipment doors (e.g. coolers, freezers, ovens).

Sufficient aisles and workspaces help facilitate access to handwashing sinks, and cleaning of equipment and

surrounding surfaces.

NOTE:

If the counter equipment is portable (e.g. toaster, blender, corer, waffle iron), clearance access criteria does

not have to be applied.

28

Protection for Foods on Display

Unwrapped foods on display at a counter, service line, display case, buffet or salad bar must be protected by

food guards (sneeze guards) or other effective means.

Self-Service

The counter height for adult self-service, including middle school and

high school students, should be 34 to 36 inches above the floor. For

sneeze guard installation, the vertical distance from the floor to the

average adult mouth height is considered 54 to 60 inches.

When elementary schools offer self-service to students in kindergarten

through fifth grade a counter height of 27 to 29 inches should be

provided. Effectiveness of the sneeze guard is based on its ability to

provide a barrier between the food and the height of students using the

serving line.

A self-service style food display should have food containers located to

accommodate the average reach of the customers normally being

served at the counter. Foods should not be displayed more than 30

inches from the serving side of the counter.

A tray slide added to the service counter, when installed, may impact

the effectiveness of the sneeze guard. Because the tray slide width

causes the customer to stand farther away from the food counter, the

direct line barrier provided by the sneeze guard, between the customer’s

mouth and the food on display, may be affected. When tray slides or

other factors may affect the sneeze guard installation, it is

recommended that the sneeze guard is designed so that it is adjustable

for height and angle alignments.

Sneeze guards should also be provided at the ends (sides) of a food

counter when foods are exposed.

Full-Service

Full-service counters including those used in elementary schools should

be 34 to 36 inches above the floor to accommodate adult food staff. An

effective food guard should be provided between the customer and the

foods on display.

Other than a hibachi style table where service is limited to customers

being served for a specific meal, a food barrier should be provided at

counters where customers are seated in view of food preparation or

cooking (e.g. sushi bar, deli counter).

29

Examples of Sneeze Guard Configurations

Self Service:

Full Service:

30

Warewashing Equipment

A mechanical or manual warewashing operation should be designed and sized to accommodate the cleaning

and sanitizing of the equipment and utensils that are to be used.

Warewashing equipment may not be used for cleaning of maintenance tools, preparation or holding of

maintenance materials or the disposal of mop water and similar liquid wastes.

Manual Warewashing

A sink consisting of no less than 3 compartments along with drainboards must meet ANSI/NSF Standard 2.

Washing, rinsing and sanitizing sink compartments should be large enough to immerse the largest

equipment or utensil to be washed (e.g. pot, lug, pan).

Drainboards provided on the manual warewashing sink should be sized to accommodate soiled equipment

and utensils prior to being washed and clean equipment and utensils after they have been sanitized to allow

air-drying. Each drainboard must be self-draining.

In addition to drainboards, utensil racks or tables large enough to accommodate all soiled and cleaned items

that may accumulate during hours of operation may be provided. Drainboards and tables being used for the

warewashing operation may not be used at the same time for food preparation.

When hot water sanitization is used, an integral heating device (sink heater) equipped with an integral

thermometer must be installed at the sanitizing compartment of the sink. A dish rack or basket for immersion

into the sink must be provided.

Warewashing sinks may not be used for handwashing.

Hot and cold water under pressure should be provided through a mixing faucet(s) that can service all

compartments of the sink. For hot water criteria, see Retail Food Establishments, Plumbing, Hot Water.

RECOMMENDATION:

Other than facilities having limited utensils to be washed, it is recommended that drainboards of at least

twenty-four (24) inches in length are provided.

31

Mechanical Warewashing

When installed, the mechanical warewashing machine must meet ANSI/NSF Standard 3 or equivalent

commercial warewashing equipment standard. The mechanical warewasher must be operated per the

manufacturer’s affixed data plate and other manufacturer’s instructions. The data plate must be positioned

so that it is accessible and readable.

Dish tables provided at the mechanical warewasher’s entrance and exit openings should be large enough to

accommodate all soiled and cleaned items that may accumulate during hours of operation. Each dish table

should be sized to accommodate at least one of the largest dish racks to be used. The lip of dish tables

should turn down inside the mechanical warewasher for seamless transfer of filled dish racks.

A pre-rinse sink should be provided in the

soiled dish table for removing gross food

particles and when necessary to soak

equipment and utensils. Some

mechanical warewashers have a pre-wash

cycle option available.

Door-type mechanical warewasher’s are

equipped with handles that extend about 3

inches away from the warewasher. When

a door-type mechanical warewasher is

installed, the length of each dish table may

need to be extended to ensure that the

dish rack rests fully on the drainboard.

Dish tables must be self-draining.

When a mechanical warewasher is used for cleaning glasses and similar equipment and utensils only,

where no gross food particles are present, a pre-rinse sink is not necessary.

A hot water sanitizing, mechanical warewasher flow pressure on the final rinse must be in the range

specified by the manufacturer but may not be:

• Less than 5 psi (pounds per square inch), nor

• Greater than 30 psi.

32

To achieve the specified flow pressure, a pressure reducing valve designed to regulate water pressure

between 5-30 psi and a pressure gauge should be provided.

A mechanical warewasher having a pumped final rinse regulated by a pump preset to operate in the

required final rinse pressure range does not necessarily need a pressure regulating valve or pressure

gauge.

Wash and final rinse temperatures must meet the minimum requirements specified on the data plate. For

additional hot water criteria, see Retail Food Establishments, Plumbing, Hot Water.

Clean in Place Warewashing

Fixed equipment (e.g. band saw, slicer, mixer) that is too large to be cleaned using manual or mechanical

warewashing equipment must be washed, rinsed and sanitized in place. Removable parts of the equipment

such as blades or mixing arms should be cleaned using the appropriate warewashing equipment.

Clean in place (CIP) equipment, such as a frozen dessert machine, that is not designed to be disassembled

for cleaning must be designed with inspection access points to ensure that food-contact surfaces throughout

the fixed system are being effectively cleaned. Internal food-contact surfaces should be cleaned following

the manufacturer’s instructions.

For water connection and drainage criteria see Retail Food Establishments, Plumbing.

Sinks

Besides the manual warewashing sink which is used for cleaning food equipment and utensils, additional

sinks are needed for handwashing, maintaining the retail food establishment and possibly food preparation.

A warewashing sink, food preparation sink, or service sink may not be used for handwashing. Handwashing

sinks, food preparation sinks and warewashing equipment may not be used for the disposal of mop water

and similar liquid waste, the cleaning of maintenance tools, or preparation or holding of maintenance

materials.

Handwashing Sink(s)

Handwashing sinks must be conveniently located in food preparation, food dispensing and warewashing

areas. Barriers such as doors (any type), curtains, speed rails, trash receptacles or equipment must not

obstruct or prevent easy access to employee handwashing stations.

Examples of inaccessible handwashing sink installation:

•

Deeply recessed under counters.

•

Located between pieces of equipment that protrude beyond the handwashing sink so that access is

inhibited.

RECOMMENDATION:

Handwashing sink placement will ultimately depend upon the layout, aisle spacing and maximum number of

employees that will work within workstations.

When planning a handwashing sink location(s), a walking distance no greater than 25 feet between the

farthest point of the workstation and the handwashing sink is suggested. In retail market prep areas, such as

meat cutting rooms, produce preparation areas and seafood preparation areas where equipment and

preparation is limited, it is recommended that the walking distance is no greater than 30 feet.

33

Handwashing sinks should be installed at a distance to

prevent splash from handwashing contamination to food,

food contact surfaces or food storage containers. When

this is not possible, a barrier such as a splash guard,

should be installed to prevent possible contamination.

When a handwashing sink is dropped (recessed) into a

food preparation table or counter, a barrier(s) should be

installed to prevent potential contamination of the counter

workspace.

Soap (hand cleanser) and disposable towels or other

hand-drying device should be installed at the handwashing

sink. To prevent potential contamination, dispensers and

devices should not be installed above or on food

preparation surfaces, food storage areas, food equipment,

or single-service and single-use articles.

Handwashing sinks are to be used for handwashing only.

Water must be provided through a mixing valve or combination faucet. For water temperature criteria, see

Retail Food Establishments, Plumbing, Hot Water.

Food Preparation Sink(s)

A food preparation sink is recommended, to minimize the potential for cross-contamination between ready-

to-eat (finished) and raw foods when a sink is routinely used for thawing, washing and/or any other food

preparation.

More than one food preparation sink may be a consideration, to prevent potential contamination of ready-to-

eat foods (e.g. fruits, vegetables, cooked proteins) by raw proteins (meats, poultry, fish), when the facility

routinely uses a sink for preparation of both food categories.

When food preparation is infrequent, or the volume is low, a dedicated preparation sink may not be

necessary.

Food preparation sinks may not be used for:

•

Handwashing,

•

Cleaning of maintenance tools,

•

Preparation or holding of maintenance materials.

•

Disposal of mop water and similar liquid wastes.

RECOMMENDATIONS:

To minimize the potential for cross-contamination due to splash, it is recommended that handwashing sinks

are installed at least 12 inches away from food and food contact surfaces.

When a barrier such as a splash guard is used, a height of 12 inches should provide effective splash control

for a standard gooseneck faucet. A splash guard height of less than 12 inches may provide effective splash

control for handwashing sinks when residential-type lavatory faucets are installed.

34

Service Sink (mop sink, can wash)

At least one conveniently located mop sink, can wash or other

curbed cleaning facility must be provided for the disposal of

mop water and similar liquid waste. The service sink should be

used for the cleaning of mops and similar wet floor cleaning

tools as well as the location used to fill mop buckets.

The basin of the service sink should be constructed of

materials that provide a smooth, nonabsorbent and easily

cleanable surface. Walls at a service sink must be smooth,

nonabsorbent and easily cleanable up to the highest level of

splash.

A toilet or urinal may not be used as a service sink. A service

sink may not be used for handwashing.

Refrigeration

Coolers (refrigerators) used to store TCS foods in areas where retail food establishment operations are

conducted must meet ANSI/NSF Standard 7. Standard 7 covers a wide range of refrigeration units (e.g.

prep coolers, walk-in coolers, reach-in coolers, beverage coolers, rapid pull-down coolers, etc.) that are

designed for specific tasks. Some sections of the standard apply to specific classes or types of coolers.

NOTES & RECOMMENDATIONS:

The installation of a floor-mounted service sink minimizes the height of splash and potential damage to the

service sink basin from the lifting of a heavy mop bucket to dispose of mop water. To restrict the flow of

sewage from traffic areas and workspaces, floor-mounted service sinks constructed on-site should be either

curbed or recessed.

A service sink(s) used for cleaning food preparation and warewashing areas should be installed in a location

that does not require traveling though customer traffic areas for mops and buckets.

It is recommended that if a service sink is installed on one floor of a food service establishment with multi-

level food preparation areas, direct access to the service sink is provided by a service elevator or service

ramp without traveling through customer traffic areas. If an elevator or service ramp is not a viable option, it

is recommended that a service basin is provided in or adjacent to each floor’s food preparation area.

35

Ambient air temperatures within a food preparation area may affect the optimal performance of some

refrigeration units.

Coolers for TCS foods must be capable of maintaining temperatures of 41

o

F (5

o

C) or below.

Beverage Cooler

Designed only for the storage/display of bottled, canned or otherwise packaged non-TCS food (e.g. soft

drinks, beer, and wine). Because beverage coolers are not designed for the storage of TCS foods,

certification is not required.

Prep Cooler

Designed with a refrigerated open top or open condiment rail (e.g. sandwich prep cooler, salad prep cooler,

pizza prep cooler, etc.) to allow easy access for assembling foods. Prep coolers are designed to maintain

cold foods cold but are not for long-term storage.

Storage Cooler (reach-in cooler)

Designed for the storage of cold, non-frozen foods between the periods of preparation, service, display or

sale. Not designed for quick chilling foods.

Walk-in Cooler/Freezers

Walk-in coolers and freezers are designed for long-term storage of TCS and perishable foods. They are

enclosed, mechanically refrigerated, storage rooms consisting of floor, walls and ceiling used to maintain

specified cold holding temperatures for food.

Floor inside the walk-in cooler or walk-in freezer may meet 6-101.11 and 6-201 in lieu of installing the

manufacturer’s flooring. Flooring material should be durable under the specified temperature conditions.

See Retail Food Establishments, Finishes (Indoor), Floor, for additional flooring guidance.

Walk-in coolers should not be confused with refrigerated food preparation/processing rooms (e.g. meat

cutting rooms, seafood preparation rooms).

Blast Chiller

Designed specifically for cooling foods to a lower temperature within a shortened time, blast chillers are often

used when a facility must cool large quantities of foods or when cooling space is limited in other refrigeration.

It is an efficient appliance for any amount of food that needs to be quickly chilled.

Service Display Cooler