Energy Storage

at Duke Energy

Tom Fenimore, PE

Emerging Technology Office

September 18

th

, 2014

ETO Technology Screening Funnel

Initial

Testing

Technology

Screening

Technology

Development

Field

Testing

Deployment into

Business unit

Energy Storage Current State

Initial

Testing

Technology

Screening

Technology

Development

Field

Testing

Deployment and

Implementation

Simple function

applications (frequency

regulation) have started

to be deployed in

certain markets (ie. PJM,

ERCOT, CAISO) – Duke

Energy’s Notrees’

Project

Integration of Energy Storage into

the vertically integrated utility ecosystem

to maximize value

is still under development

Energy Storage Benefits

Generation

T & D

End User

Frequency Regulation

Defer System Upgrades

Provide Back Up Power

Renewable Smoothing

Improve Reliability

Utilize lower retail rates

Energy Shifting

Renewable Smoothing

Spinning and Non-

spinning Reserves

Improve Power Quality

(Volt / VAR management)

Limit Peaker Plant Builds

Through pilots we

understand…

Capital Costs

O & M Costs

Installation Hurdles

Operational Issues

Value Streams

…to develop

Business models

Regulatory models

Understand benefits

4

How did

Duke Energy

get here?

Over 25

6

Five differe

locatio

>25

6

Six unique

demonstration projects

installed

functions

Six different

battery chemistries

tested

5

nt

ns

How did

Duke Energy

get here?

Benefit:

Connected on:

• Transmission

• Distribution

• Customer

• With renewables

Diverse chemistries in different capacities

kW

kWh

200 400 600

800

200

400

600

800

25kW/25kWh

Lithium Ion

250kW/750kWh

Lithium Polymer

36MW/24MWh

Advanced Lead Acid

200kW/500kWh

Li Iron Phosphate

200kW/500kWh

Sodium Nickel

75kW/42kWh

Lithium Titanate

How do

SIZE LOCATION

CHEMISTRY FUNCTION

enable value?

on the grid

demonstrated

Notrees Wind Farm Project

Notrees, TX

Major system components:

• 36 MW / 24 MWh

• Xtreme Power Advanced Lead Acid Technology

• Co-located at site of 156 MW Wind Farm in Notrees,

Texas

• Began commercial operation in December 2012

• 50:50 Cost share with DOE

Applications being tested

1 – Ancillary Services: participating in a series of ERCOT

(Texas ISO) market tests to learn how to structure an

efficient market that enables energy storage to provide

ancillary services to the grid.

2 – Energy Shifting: Charging and discharging to maximize

the value of energy delivered to the grid based on timing.

3-Avoiding Wind Curtailment : Using storage to store wind

energy in order to avoid orders to cease providing power to

the grid.

Example: Texas and ERCOT (Electric Reliability Council

of Texas)

• Texas has seen a large amount of wind growth over the

past 10 years.

• This has the created the need for fast responding

resources such as energy storage to help stabilize the

grid

Texas alone has more

wind than France.

15

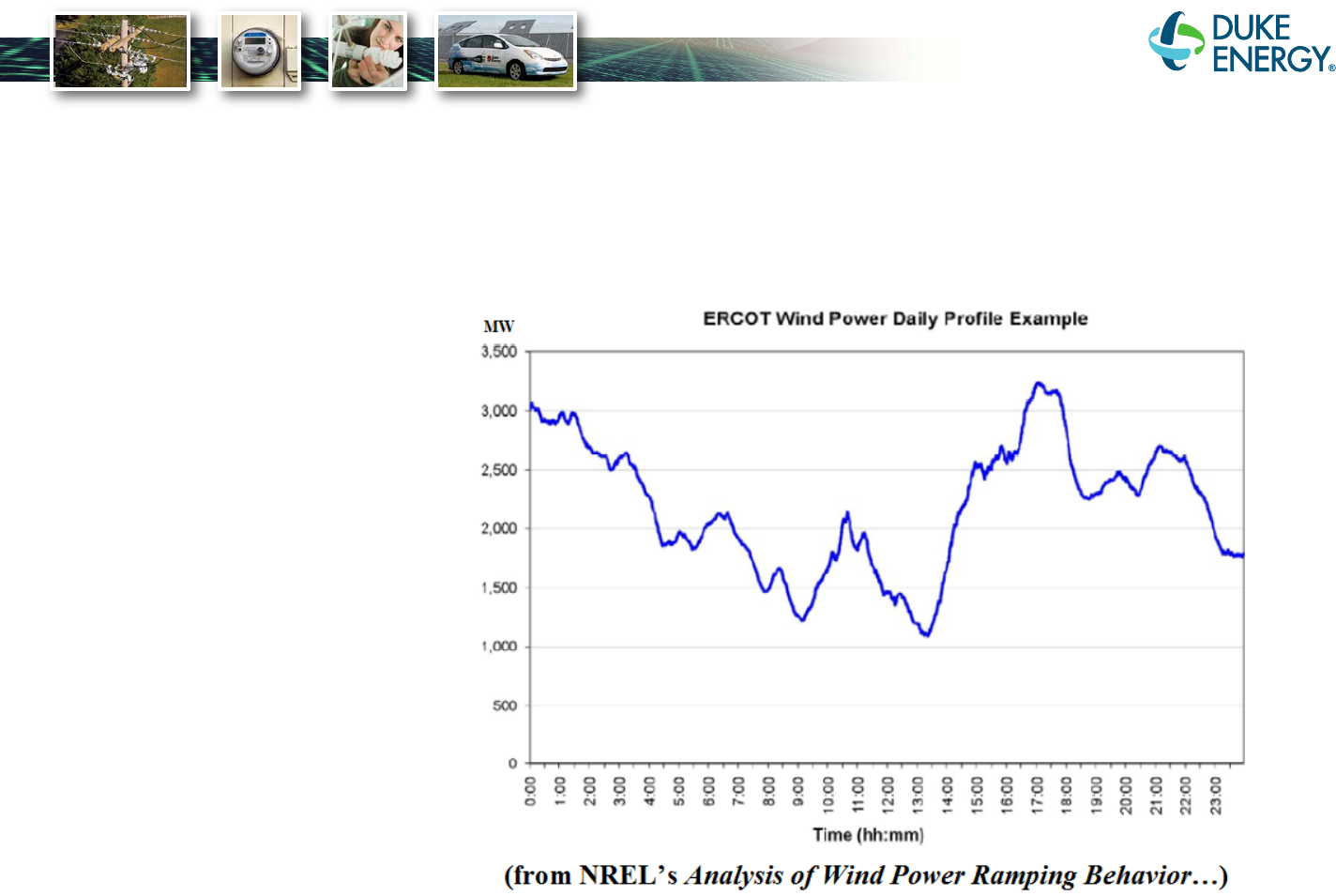

Example of Daily Wind Output in ERCOT

Wind is highly variable

(the graph to the right

shows a daily wind

profile in Texas)

which makes balancing

supply and demand very

difficult. Fast

responding resources

such as battery

energy storage can help

solve this problem.

16

Example of Battery’s Output and Response Time

Duke Energy’s 36 MW / 24 MWh battery charging and discharging based off market signals to

help with grid stability

17

Discharging

Charging

McAlpine Energy Storage System

McAlpine Creek Retail Substation, Charlotte, NC

Major system components:

• 200 kW / 500 kWh system capacity

• BYD battery and inverter system

• All components integrated within on container

• Lithium-iron-phosphate battery (BYD)

Interconnection:

• Located on a 24 kV distribution circuit

• Interconnected immediately outside of the substation

• Adjacent to 50 kW solar facility on McAlpine test circuit

BYD battery

200 kW/500 kWh LiFePO4

Inverter/Controls

Integrated within one container

System attributes

• In service 4Q 2012

x

• Interconnected next to a 50 kW

solar facility in a planned

islandable micro-grid scheme

that will use the battery for grid

frequency/voltage regulation.

Applications being tested

1 – consolidated inverter/battery construction at a low price

2 – energy shifting applications

a) dispatched based on schedule, local load peaks, etc

3 – integration with solar in a microgrid

a) will be configured with switches, solar, and load to create

an autonomous microgrid that disconnects from the circuit

4 – solar output smoothing/firming

Solar

Islandable Microgrid Schematic

SS

McAlpine Crk.

Retail

Sola

r

Battery

120/208 V

480/277 V

24 kV

24 kV

Ckt 2414

Electronic switch w/

DG protective settings:

“DG Switch”

Normally Closed

75 kVA

(3 x 25 kVA)

Fire

Station

200 kVA

500 kWh

50 kW

Electronic switch to

disconnect from grid:

“Islanding Switch”

Normally Closed

500 kVA

Equipment

Legend

Microgrid

Controller

Manual

Disconnect

Point of common

coupling

Existing

New

Sense

& Control

AC

DC

AC

DC

Inverter

Inverter

19

Microgrid Controller HMI

Rankin Energy Storage System

Rankin Ave. Retail Substation, Mount Holly, NC

Major system components:

• 402 kW / 282 kWh system capacity

• FIAMM sodium nickel chloride battery

• 12 Zebra bus batteries connected in parallel

• 1.25 MVA S&C Electric Company Inverter (SMS)

Interconnection:

• Located on a 12.47 kV distribution circuit

• Interconnected immediately outside of the substation

• Circuit contains a 1.2 MW solar facility ~3 miles away

System attributes

• Installed Dec 2011, in service Mar 2012

• Remotely operable

• ZEBRA bus batteries by FIAMM

for stationary application

development

• Contains fiber connection to

substation relaying; no

connection to the solar facility

on the circuit

1000 kVA transformer

Auxiliary power load center

Steps up 480 V inverter

120V/240V service

output to 12.47 kV

Battery container

Inverter/Controls

402 kW/282 kWh NaNiCl

Storage Management System (SMS)

batteries (12 cells)

1.25 MVA capacity/1.0 MVAR capacity

Applications being tested

1 – centralized solar-induced power swing mitigation

a) senses substation real power loading and uses battery to

“smooth” rapid ramp rates caused by cloud-induced solar

intermittency

b) no direct connection to the solar – designed to smooth

power swings from multiple dispersed solar sites on a circuit

2 – active VAR/power factor management

3 – combined watt/VAR voltage control

a) compensation for rapid solar-induced voltage changes

kW (circuit loading)

(Battery Output)

2550

2500

800

2450

2400

600

2350

discharge

charge

2300

400

2250

2200

200

kW

2150

2100

0

2050

2000

-200

08:00 08:07 08:14 08:21 08:28 08:36 08:43 08:50 08:57 09:04 09:12

Original Circuit Load - Before Smoothing

Target Circuit Load

Measured Circuit Load - After Smoothing

Target Battery Output

Actual Battery Output

Marshall Energy Storage System

Marshall Steam Station, Sherrills Ford, NC

Major system components:

• 750 kWh / 250 kW system capacity

• Kokam Superior Lithium Polymer Batteries

• 1.25 MVA S&C Electric Company Inverter

(SMS)

Interconnection:

• Located on a 12.47 kV distribution circuit

• Separate but adjacent medium-voltage interconnection

from 1.0 MW solar facility

• Located at the end of a distribution feeder

System attributes

• Installed May 2012, in service July 2012

• Remotely operable

• Battery and inverter independently

sourced (both vendors to Duke)

• Located at the Marshall solar test site

where multiple solar technologies are

being field tested on a sealed coal-ash

landfill

1000 kVA transformer

Inverter/Controls

Steps up 480 V inverter

Storage Management System (SMS)

output to 12.47 kV

1.25 MVA capacity/1.0 MVAR capacity

Battery container

750 kWh/250 kW Lithium Polymer

Includes Batt. Mgt. System

1.2 MW solar facility

Applications being tested

1 – energy shifting

a) for system-level arbitrage

b) for local operational constraint management

c) based on forward-looking economic algorithm

2 – solar output smoothing and firming

a) for local feeder voltage management

b) solar-induced power swing mitigation

3 – active VAR/power factor management

4 – combined algorithms / optimization

a) combined energy shifting and smoothing algorithm

b) use of distributed logic with economic, substation, and

local input parameters

Battery

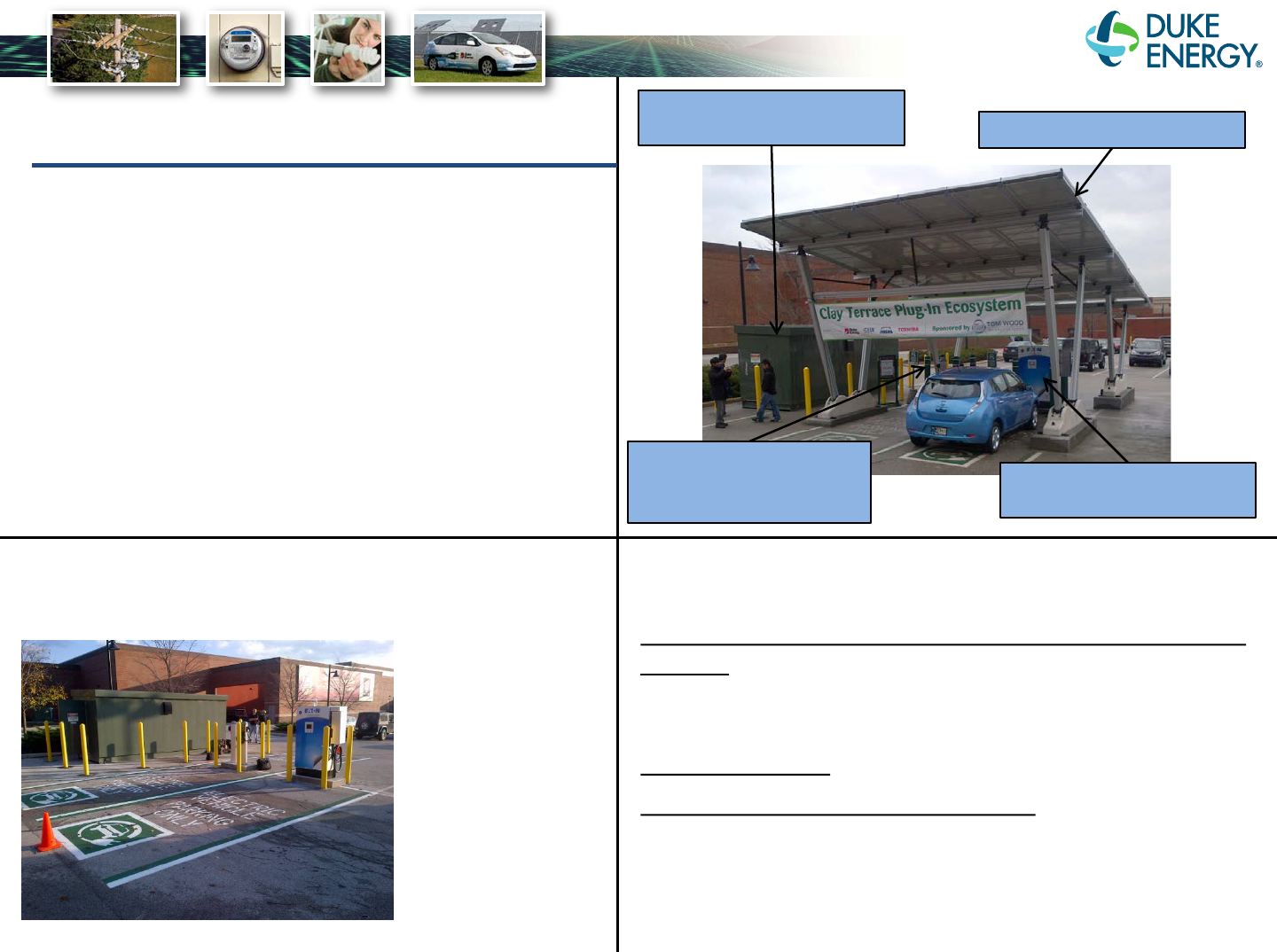

Clay Terrace Energy Storage System

Clay Terrace Mall, IN

Major system components:

• 75 kW / 42 kWh system capacity

• Toshiba lithium titanate battery

• 10 kW roof-mounted solar

• Eaton 50 kW, Siemens 3.3 kW PEV charging stations

Interconnection:

• Behind a commercial meter (customer sited)

• Interconnected at 480V, 3-phase transformer

• Located in the parking lot of a shopping mall

System attributes

• Installed 3Q 2012, in service 4Q 2012

• Designed to

manage and

optimize the

combined energy

profile of solar,

PEV charging, and

storage.

75 kW / 42 kWh Toshiba Li-Titinate

10 kW solar roof-top

PEV DC Fast charging station

50 kW Eaton unit

Level 2 PEV charging

station

J1772 up to 3.3 kW charging

Applications being tested

1 – active management of combined solar, storage and PEV

charging

a) testing energy management system and sizing of a

behind-the-meter system

2 – energy shifting

3 – customer-sited installation aspects

Battery Responding to DC Charge Event

Community Energy Storage Systems

Two units installed

McAlpine 24 kV circuits, Charlotte, NC

Major system components:

• 25 kVA inverter system – S&C Electric Company

• Kokam 25 kWh / 25 kW lithium ion battery

• Battery located in underground vault

Interconnection:

• Interconnected at 120V/240V split single phase

• Configured to serve up to five customers on 50 – 75 kVA

padmount transformers

• Initially connected to one customer each for testing

System attributes

• Installation: unit 1 - Oct 2011; unit 2 - Dec 2011

• Remotely operable and

monitored via DMS

• Demonstrating underground

battery vault configuration

Inverter/control unit

50 kVA secondary

25 kVA connected at 120V/240V

transformer

Battery vault

Battery (underground in vault)

4-feet deep, open bottom

25 kW / 25 kWh Kokam Li-ion battery

pack

Applications being tested

1 – automatic voltage managment

a) automatically injects/consumes VARs to maintain voltage

within a specified setpoint

2 – islanding/back-up power

a) automatic islanding during a grid outage

3 – distributed energy shifting

a) various energy shifting applications using a network of

distributed batteries

4 – control system for distributed storage

a) using distributed communications network to monitor

and dispatch the battery

Need to Consider

• Physical vs. Virtual Energy Storage

• How will energy storage compete / work

together with:

– Smart Invertors

– Demand Response

– Devices which perform autonomous frequency

regulation

Conclusions

• The electric grid is changing: Electric generation is

becoming more “de-centralized” – moving closer to

the end user

• Balancing supply and demand requires a highly

interconnected ecosystem with constant

communication between assets

• Understanding how energy storage can seamlessly be

integrated in this ecosystem is still under development