Wastewater Energy

Management

Best Practices Handbook

March 2019

2

Table of Contents

1 Introduction ...............................................................................................................................5

1.1 Background ................................................................................................................................... 5

1.2 Description of New York State’s Wastewater Sector.................................................................... 6

1.3 Overview of New York State’s Clean Energy Goals ....................................................................... 7

1.4 Current Trends Affecting Energy Use in Wastewater Sector ........................................................ 7

Resource Recovery and Emerging Technologies .................................................................. 8

1.5 Purpose ......................................................................................................................................... 9

2 Energy Management Program Development ............................................................................. 10

2.1 Understanding Energy Management Opportunities .................................................................. 10

Improving Energy Efficiency and Managing Total Energy Consumption ............................ 10

Controlling Peak Demand for Energy .................................................................................. 11

Managing Energy Cost Volatility ......................................................................................... 12

Improving Energy Reliability ............................................................................................... 12

Opportunities for Renewable Energy ................................................................................. 12

Energy from Biogas ......................................................................................................................... 13

Energy from Photovoltaic Systems ................................................................................................. 13

Energy from Wind ........................................................................................................................... 13

2.2 Basic Steps Involved in Building an Energy Program .................................................................. 14

Step 1: Establish Organizational Commitment via Strategic Energy Management (SEM) . 14

Step 2: Develop Baseline Energy Use .................................................................................. 15

Step 3: Evaluate the System and Collect Data .................................................................... 16

Step 4: Identify Energy Efficiency Opportunities ................................................................ 16

Step 5: Implement No- and Low-Cost Opportunities.......................................................... 17

Step 6: Prioritize Remaining Opportunities for Implementation ........................................ 17

Step 7: Develop an Integrated Capital/Energy Plan ............................................................ 18

Step 8: Track and Report Success ....................................................................................... 18

2.3 Constraints to Implementing an Energy Program ...................................................................... 19

3 Energy Management Best Practices ........................................................................................... 20

3.1 Renewable Distributed Generation Best Practices ..................................................................... 21

R1—Generate Energy from Biosolids ............................................................................................. 21

R2—Increase Energy Generation with Co-Digestion of Source-separated Organics ...................... 22

R 3—Install Wind Generation System ............................................................................................. 23

R 4—Install Solar Photovoltaic Generation System ........................................................................ 24

3.2 Organizational Energy Management Best Practices ................................................................... 25

Cover Image: Getty Images

3

O 1—Facility Energy Assessments .................................................................................................. 25

O 2—Real Time Energy Monitoring ................................................................................................ 26

O 3—Energy Education for Facility Personnel ................................................................................ 27

O 4—Comprehensive Planning Before Design ................................................................................ 28

O 5—Design Flexibility for Today and Tomorrow ........................................................................... 29

O 6—Electric Peak Reduction ......................................................................................................... 30

O 7—Manage Electric Rate Structure ............................................................................................. 31

O 8—Certification Programs—LEED, Envision, BREEAM ................................................................ 32

3.3 Treatment Process Energy Management Best Practices ............................................................ 33

WW 1—Operational Flexibility ....................................................................................................... 33

WW 2—Staging of Treatment Capacity .......................................................................................... 34

WW 3—Manage for Seasonal/Tourist Peaks .................................................................................. 35

WW 4—Flexible Sequencing of Basin Use ...................................................................................... 36

WW 5—Idle or Turn off Equipment ................................................................................................ 37

WW 6—Electric Motors: Install High-Efficiency Motors ................................................................. 38

WW 7—Electric Motors: Automate to Monitor and Control ......................................................... 39

WW 8—Supervisory Control and Data Acquisition (SCADA) .......................................................... 40

WW 9—Electric Motors: Variable Frequency Drives Applications ................................................. 41

WW 10—Electric Motors: Correctly Size Motors ........................................................................... 42

WW 11—Electric Motors: Properly Maintain Motors .................................................................... 43

WW 12—Electric Motors: Improve Power Factor .......................................................................... 44

WW 13—Pumps: Optimize Pump System Efficiency

...................................................................... 45

W

W 14—Pumps: Reduce Pumping Flow ........................................................................................ 46

WW 15—Pumps: Reduce Pumping Head ....................................................................................... 47

WW 16—Pumps: Avoid Pump Discharge Throttling ....................................................................... 48

WW 17—Optimize Grit Removal System ........................................................................................ 49

WW 18—Chemically Enhanced Primary Settling ............................................................................ 50

WW 19—Optimize Aeration System ............................................................................................... 51

WW 20—Fine-Bubble Aeration....................................................................................................... 52

WW 21—Variable Blower Airflow Rate .......................................................................................... 53

WW 22—Dissolved Oxygen Control ............................................................................................... 54

WW 23—Filtration: Sequence Backwash Cycles............................................................................. 55

WW 24—Post-Aeration: Cascade Aeration .................................................................................... 56

WW 25—Ultraviolet (UV) Disinfection Options .............................................................................. 57

WW 26—UV Disinfection: Install Dose Pacing ................................................................................ 58

WW 27—Sludge: Improve Solids Capture in DAF System .............................................................. 59

WW 28—Sludge: Replace Centrifuge with Screw Press ................................................................. 60

WW 29—Sludge: Replace Centrifuge with Gravity Belt Thickener ................................................. 61

WW 30—Biosolids Digestion Options ............................................................................................. 62

WW 31—Aerobic Digestion Options ............................................................................................... 63

WW 32—Biosolids Mixing Options in Aerobic Digesters ................................................................ 64

4

WW 33—Biosolids Mixing Options in Anaerobic Digesters ............................................................ 65

WW 34—Optimize Anaerobic Digester Performance..................................................................... 66

WW 35—Cover Basins for Heat Reduction ..................................................................................... 67

WW 36—Recover Excess Heat from Wastewater .......................................................................... 68

WW 37—Reduce Fresh Water Consumption/Final Effluent Recycling........................................... 69

3.4 Building Systems Energy Management Best Practices ............................................................... 70

B 1—Annual Compressed Air Leakage Survey ................................................................................ 70

B 2—Optimize Compressed Air System Pressure ........................................................................... 71

B 3—Install VFD Control on Air Compressors ................................................................................. 72

B 4—Boiler and Furnace Maintenance ........................................................................................... 73

B 5—Boiler and Furnace System Maintenance .............................................................................. 74

B 6—Implement Burner Management System ............................................................................... 75

B 7—Implement Boiler Stack Economizers ..................................................................................... 76

B 8—Ventilation Damper and Fan Maintenance ............................................................................ 77

B 9—Replace Ventilation Air Filters ................................................................................................ 78

B 10—Optimize Ventilation System Control Strategies .................................................................. 79

B 11—Clean Lamps and Fixtures ..................................................................................................... 80

B 12—Replace Inefficient Lighting with High-Efficiency Lighting ................................................... 81

B 13—Implement Lighting Control ................................................................................................. 82

4 References ............................................................................................................................... 83

Appendix A. Understanding the Electric Bill .................................................................................... A-1

Appendix B. Example Spreadsheet Showing Baseline of Energy Use ................................................ B-1

Appendix C. Economic Evaluation Methods .................................................................................... C-1

5

1 Introduction

The New York State Energy Research and Development Authority (NYSERDA) promotes energy efficiency

and the use of renewable energy sources. These efforts are key to developing a less polluting and more

reliable and affordable energy system for all New Yorkers. Collectively, NYSERDA’s efforts aim to reduce

greenhouse gas emissions, accelerate economic growth, and reduce customer energy bills. Governed by

a 13-member board, NYSERDA has provided objective information and analysis, technical expertise, and

support in New York State since 1975. The stated mission and vision of NYSERDA are as follows:

Advance innovative energy solutions in ways that improve New York State's economy and

environment.

Serve as a catalyst—advancing energy innovation, technology, and investment;

transforming the State’s economy; and empowering people to choose clean and efficient

energy as part of their everyday lives.

With this charge, NYSERDA identified the municipal wastewater sector as a target to strategically reduce

energy consumption in New York State.

1.1 Background

The primary goal of the wastewater sector has been to meet regulatory requirements for the protection

of human health and the environment. The sector has focused on maintaining compliance with

discharge requirements regulated by the New York State Department of Environmental Conservation

(DEC) through the New York State Pollutant Discharge Elimination System (SPDES) program. Historically,

to ensure achievement of this primary objective, many facilities within the wastewater sector were not

designed to operate with a goal of reducing or optimizing energy use.

A secondary goal of the wastewater sector is to provide services for reasonable and fair user fees or

rates. These fees are typically developed based on the debt service for capital improvements, operating

expenses (labor, energy, chemical, etc.) and reserve accounts. Many wastewater utilities treat energy

costs simply as a cost of doing business, without significant effort to effectively mitigate cost increases.

As a result, capital reserves are often depleted to offset rising operating expenses in an effort to

maintain stable user fees. Funding operations in this manner leaves the utility vulnerable to unforeseen

capital expenditures and may result in inadequate investment in the upkeep, maintenance, and upgrade

of process equipment and facilities, or cause utilities to base all equipment purchases solely on initial

capital cost, rather than considering the life-cycle cost of owning and operating the equipment.

6

1.2 Description of New York State’s Wastewater Sector

In New York State, municipal wastewater utilities provide services to nearly 95% of the State’s

population. The municipal wastewater sector includes 702 water resource recovery facilities (WRRFs)

with a combined design treatment capacity of 3.7 billion gallons per day (DEC 2004).

NYSERDA conducted statewide assessments of energy use by New York State’s wastewater sector in

both 2003/2004 (Yonkin, 2008) and 2012/2013 (ENER7C13a, Andrews, 2015). On an aggregate basis,

statewide energy use (total kilowatt-hours per year; kWh/year) and normalized energy use (kWh per

million gallons; kWh/mg) have increased over the almost decade between studies, despite lower flows

and nearly level biochemical oxygen demand (BOD) loads. The increase is due to more stringent nutrient

removal standards, which have triggered modifications at several large plants, and double-digit

percentage declines in flow at more than 100 of the 189 plants with average design flow greater than

one million gallons per day. A summary of pertinent results from both studies are presented in Table 1.

Table 1. Energy Used by Wastewater Treatment Sector in New York State

Plant Size

Category

(Based on

Design Flow)

Number of

WRRFs

a

2003/2004

2012/2013

Energy Use

(kWh/mg)

% of

Treatment

Capacity

% of Electric

Energy Use

Energy Use

(kWh/mg)

% of

Treatment

Capacity

% of Electric

Energy Use

Statewide

average

---------- 1,755

c

---------- ---------- 1,800 ---------- ----------

< 1 mgd 520 4,620

b

4 11 ---------- 5 12

1 - 5 mgd 106 2,200

c

7 8 2,300 6 8

5 - 20 mgd 43 1,740

b

13 14 1,970 12 12

20 - 75 mgd 19 1,700

b

24 27 1,370 22 19

> 75 mgd 14 1,100

b

52 40 1,280 55 49

a Source: DEC 2004 Descriptive Data

b Source: Yonkin, M; 2008.

c Source: Andrews, N, Willis, J, Nascimento, D; 2015

7

1.3 Overview of New York State’s Clean Energy Goals

New York State’s Clean Energy Standard (CES) is the most comprehensive and ambitious clean energy

goal in the State's history. The CES is designed to fight climate change, reduce harmful air pollution, and

ensure a diverse and reliable low-carbon energy supply. Reforming the Energy Vision (REV) is New York

State’s strategy to develop a clean, resilient, and affordable energy system for all New Yorkers. This

comprehensive effort sets the State on a realistic path to achieving its long-term environmental and

economic development goals, including the Clean Energy Standard commitment that will require 50% of

electricity to be sourced from renewable energy sources by 2030. Other components of REV include

groundbreaking regulatory reform and leading by example through public investment in energy

efficiency and renewable energy.

The Clean Energy Fund (CEF) supports the CES commitment by reducing the cost of clean energy and

accelerating the adoption of energy efficiency to reduce load while increasing renewable energy to meet

demand. Among other solutions, the CEF offers to reduce greenhouse gas emissions through increased

efficiency and use of renewable energy. NYSERDA continues to collaborate with all sectors, including

wastewater, to collectively identify and address critical barriers to energy efficiency and clean energy.

1.4 Current Trends Affecting Energy Use in Wastewater Sector

Recent updates have been implemented to SPDES permits for WRRFs across the State that require

disinfection, have more stringent limits for nitrogen forms, or enforce the reduction of combined or

separate sewer overflows (CSO/SSO). While these stringent limits are being enforced by the DEC to

protect the waters of New York State, WRRFs that need to maintain compliance with their newly issued

permits may see an increase of energy use with the installation of ultraviolet (UV) disinfection systems,

larger blower power consumption for nitrification, additional flow being treated that was previously

discharged during wet weather events, or installation of solids and floatable materials control

equipment that had not previously existed.

WRRFs are encouraged to seek the most energy-efficient system when installing new equipment; for

example, by following the recommended best practices provided in this handbook and considering the

life-cycle cost of new projects (see Appendix C: Economic Evaluation Methods). Proposed projects

applying for funding through the New York State Environmental Facilities Corporation (EFC) are required

to identify energy efficiency measures, energy costs and payback, and comply with EFC’s endorsement

of energy reduction in the wastewater sector.

Climate change and extreme weather events are causing municipalities to implement resiliency plans

through the protection of equipment and relocation of key process components. Additional pumping to

higher ground surface elevations might be introduced to avoid the risk of flooding but introduces

additional use of energy. Another component of resiliency plans is typically a strategy for reduction of

greenhouse gases (GHG), either direct (e.g., fuel use) or indirect (e.g., electricity use), which ties back

into New York State’s clean energy goals and REV.

8

Resource Recovery and Emerging Technologies

WRRFs no longer just treat water and generate waste as a by-product, but recover resources that are

embedded in wastewater, such as energy, renewable natural gas (biogas), nutrients, and clean water.

Added benefits of energy and biogas recovery are the reduction in quantity of solids disposed of in

landfills, pathogen reduction in biosolids, and reduction in fossil fuel extraction. Nutrients recovery

offsets the manufacture and application of synthetic fertilizers, while reducing nutrients discharged

to waterways.

There are a few proprietary technologies that can be used to recover dissolved phosphorus from

digested sludge and digester supernatant to produce a marketable mineral fertilizer. The first step of

these processes is biological or chemical phosphorus removal from wastewater to transfer phosphorus

to the sludge. Next, chemical treatment is used to form a phosphorus mineral, such as struvite, that can

be sold to generate revenue.

Biogas generated by anaerobic digesters contains approximately 60% methane. The remaining

components are carbon dioxide, water, and other impurities such as hydrogen sulfide and siloxanes.

Biogas can be treated to separate methane from the other constituents. The resulting product is

relatively pure methane that meets quality standards of pipeline natural gas, also called renewable

natural gas (RNG), which qualifies under the Renewable Identification Number (RIN) program when used

for vehicle fueling. Petroleum producers are obligated to meet a certain quota of RINs, so there is a

trading market for them, from which the WRRF can have an economic benefit. Economic incentives can

also be associated with recovering renewable energy from the WRRF, in the form of Renewable Energy

Certificates (RECs), which can be sold to create a supplemental revenue stream in addition to the

avoided cost for purchasing electricity that is generated with the recovered biogas.

Some promising new technologies are being researched to reduce energy use in systems that are

currently energy intensive. For example, shortcut nitrogen removal uses anaerobic ammonium oxidizing

(anammox) bacteria that convert ammonia to nitrogen gas without the requirement of additional air or

carbon. This system has application in sidestreams such as nitrogen-loaded anaerobic digester

supernatant and dewatering waste, as well as mainstream systems.

Post Aerobic Digestion (PAD) is the addition of an aerobic digester following the anaerobic digestion

process. PAD provides additional destruction of volatile solids, improving dewatering performance and

reducing the volume of disposed biosolids. It also can remove ammonia and organic sulphur compounds

(a source of odors). The PAD process increases annual aeration costs but eliminates the need for a

separate sidestream treatment process to manage nitrogen and can reduce some ortho-phosphorus by

forming struvite as the reactor pH increases.

Another emerging technology in digester enhancement is waste activated sludge (WAS) hydrolysis,

which is a process where the cell walls of the bacteria contained in WAS are ruptured (lysed). The

process can be accomplished by mechanical, thermal, chemical, or pressure-based means or a

combination of several of these methods. The process offers many advantages, such as increased solids

retention time (SRT) and reduced digester heating loads; improved digestibility, resulting in enhanced

biogas production; and improved dewaterability resulting in reduced volumes of disposed biosolids.

9

Aerobic granular sludge is a proprietary innovative biological wastewater treatment technology that

provides simultaneous BOD, nitrogen, and phosphorus removal in a reduced-volume footprint. Low

energy requirements are associated with increased tank depth that increases aeration efficiency,

elimination of return sludge, and nitrate recycle streams and elimination of mixing. The process is still in

its relative infancy but has been tested in a sequencing batch reactor process with success.

An emerging technology that is at the forefront of the dynamic changes occurring in New York State’s

energy sector is energy storage. Water utilities, which operate using energy day and night to move and

treat water, can install batteries to store energy overnight, when energy is cheaper, and tap into that

power during the daytime, when power is more expensive. This also helps the electric grid meet

demand during peak hours by enabling the WRRF to use battery storage to offset a portion of its

daytime energy use.

1.5 Purpose

The wastewater sector’s primary objectives remain unchanged—meeting regulatory requirements and

protecting public health. However, with rising energy costs, a greater financial burden placed on local

governments, and a public sentiment toward sustainability and resiliency, improving energy efficiency

and optimizing energy management at WRRFs (one of the larger energy users under the control of a

typical municipality) are paramount.

Energy efficiency and the protection of public health and the environment are not mutually exclusive.

Often, energy conservation programs not only reduce the amount of energy utilized at a facility, but also

provide improved control and operation of unit treatment processes—satisfying both the wastewater

sector’s primary and secondary objectives.

The purpose of this Wastewater Energy Management Best Practices Handbook is to provide the

wastewater sector with guidance on the development of an energy conservation program,

implementation of capital and operational improvements to reduce energy consumption, and methods

to track performance and assess program effectiveness.

10

2 Energy Management Program Development

2.1 Understanding Energy Management Opportunities

Wastewater utilities are tasked with the mission of minimizing the costs associated with protecting

water resources while maintaining a high degree of reliability. In part, these can be addressed by

the following:

Improving energy efficiency and managing total energy consumption

Controlling peak demand for energy

Managing energy cost volatility

Improving energy reliability

Good energy management practices avoid unanticipated costs, maximize all possible energy and

cost savings opportunities, and often overlap with other utility best management practices. For

example, an effective preventive maintenance program improves motor efficiency and also increases

system reliability. Similarly, improvements to the overall efficiency of wastewater treatment enhance

energy performance as measured by some energy benchmarks or key performance indicators, such

as gallons of water treated per kilowatt-hour of electricity consumed. Good energy management

practices can also have ancillary benefits, such as enhanced staff communications and morale,

increased public perception, and a more comprehensive understanding of the treatment process.

Ancillary benefits should always be taken into consideration when evaluating prospective energy

management opportunities.

Conventional wastewater treatment is intrinsically energy intensive, due in part to the need to deliver

large volumes of oxygen via high-horsepower blowers to support the secondary treatment process.

Pumping, which is also core to the treatment process of most WRRFs, is also an inherently energy

intensive process. One of the biggest drivers for improving energy efficiency is often cost, which is based

on two main components, the quantity of electricity used and the demand for electricity. The next

sections provide greater detail on both components.

Improving Energy Efficiency and Managing Total Energy Consumption

The quantity of electricity is measured in kilowatt-hours and reflects the amount of physical “work” that

can be performed by the electricity. Electric utility rates typically include an energy consumption charge

that is based on the number of kilowatt-hours consumed per billing cycle, and often the charge is

further subdivided by “on-peak” versus “off-peak” consumption, where on-peak rates are higher than

off-peak rates. Understanding the electric utility’s pricing policies, or rate structures, is critically

important to planning energy management programs that provide the greatest financial benefit. A

detailed discussion of electric utility rates, bills, and kilowatt-hours is provided in Appendix A.

11

WRRFs can, and should, set energy reduction goals, whether it be a small goal to partially reduce electric

consumption and costs or a more aggressive goal to become a net zero energy or carbon neutral facility.

The amount of energy used by a utility for wastewater treatment is a function of various factors,

including topography of the service area, system size, treatment process, type and condition of

equipment, regulatory requirements, and operation and management (O&M) practices. Since no

treatment system operates at 100% efficiency, opportunities exist at all WRRFs to improve energy

efficiency and reduce the total consumption of kilowatt-hours.

An example of an energy conservation measure that focuses on improving energy efficiency would be

more closely matching blower and motor size to oxygen demand in the WRRF’s secondary treatment

system. Blowers are often sized based on the maximum capacity required at peak conditions and have

limited turndown capability to match the more frequently occurring average or minimum air

requirements, which may vary based on hourly influent loading and temperature conditions. Overall

design parameters might have changed since the original WRRF design due to unrealized growth

projections, decreases in local population, or changes in industrial contributions. If the existing blower

has sufficient turndown capability, automated controls that adjust the blowers’ airflow based on actual

oxygen demand can help provide the right amount of air (and energy) from the blowers. However, if

blowers are limited in their turndown, then a new blower solution may be warranted. Similarly, in some

situations the diffusers, either due to fouling or a less efficient design, are the greatest source of

inefficiency in an aeration system, requiring significantly greater air to deliver the same amount of

useable oxygen. In those situations, replacement of the diffusers may be a more appropriate first step.

Controlling Peak Demand for Energy

Electric utilities typically include a “demand charge” in their rate structure that can account for

anywhere from 30 to 60% of the overall cost of electricity for a typical WRRF. The demand charge is

based on the customer’s maximum demand for electricity (kilowatts) measured during a billing period

and allows the electric utility to recover the capacity costs required to meet each customer’s maximum

energy needs.

From the electric utility’s perspective, a high degree of variability in customer demand is the most

difficult situation to plan for and requires a large investment in capital. Consequently, electric utilities

will reward customers that can demonstrate a low variability in electric demand over time, or

“flattened” demand curve. This includes two separate but related goals:

Minimizing changes in peak demand throughout the course of a billing period.

Shifting loads from peak periods, typically during daylight hours, to “off-peak” periods.

Wastewater utilities can realize significant savings in electric costs by minimizing demand charges.

Sometimes this can be done indirectly by reducing the variability in demand placed on their own

systems, through measures such as addressing infiltration and inflow, or providing equalization for

industrial loadings and feeding them to the aeration tanks over a longer period of time to flatten

aeration demands during peak periods. Other strategies focus on shifting loads to off-peak periods or

12

flattening demand by minimizing the overlap between treatment processes. Conducting intermittent

dewatering operations during off-shifts is an example of this.

Managing Energy Cost Volatility

The price of energy, including electricity, natural gas, and fuel, can vary significantly from day to day, or

year to year. However, wastewater utility revenues are less variable by nature, and therefore dramatic

changes in energy costs can severely stress utility budgets and disrupt other programs.

From a utility management perspective, protecting against volatility in costs is an important goal

that should not be overlooked or undervalued in the energy planning process. Wastewater utilities

have a variety of strategies available to protect against volatile energy prices. Examples include the

long-term procurement of energy, and provisions for alternative energy sources and/or on-site

generation of energy.

Improving Energy Reliability

As many local and system-wide power outages have proven in the past, energy, like money, water,

or air, becomes noticeably more important when it is unavailable. Good design practices, as well as

State statutes require wastewater utilities to provide critical systems with adequate backup power.

The energy planning process should also identify opportunities to improve energy reliability

whenever possible.

Reliability improvements can include protection against complete loss of power, as well as identifying

changes in power quality (e.g., under voltage, power harmonics, or power surges) that can damage

equipment, or instituting operating procedures to address changes in power availability. On-site

distributed generation systems are an obvious opportunity to enhance reliability.

In recent years, the New York Independent System Operator (NYISO), the organization responsible for

coordinating electrical demand throughout the State, has also offered various opportunities for large

customers of power to participate in demand management programs. Customers are generally required

to have generators rated 100 kilowatts (kW) or higher, or to be capable of reducing at least 100 kW of

load. These programs are designed to heighten regional power reliability, while offering participating

customers a revenue source in exchange for curtailing their energy use during high-demand periods by

transferring load to on-site electricity generating resources.

Opportunities for Renewable Energy

WRRFs with a permitted flow rate larger than 5 million gallons per day (mgd) have a significant potential

to generate electricity and heat from biosolids. WRRFs with lower permitted flow rates also have the

potential to generate electricity and heat from biosolids if they combine these with high-strength

organics from outside generators or consolidate solids handling operations with other small utilities.

13

WRRFs treating sludge in anaerobic digesters can set a goal of using biogas in a combined heat and

power (CHP) system to generate electricity that can be used to offset the on-site power demand and

heat to offset the digester heating requirement. WRRFs already recovering energy from biogas can

explore accepting high-strength waste in co-digestion to boost biogas production to maximize utilization

of existing resources and capacity or to help drive expansion of on-site recovery activities.

Energy generation from renewable resources such as wind and sun can be an additional distributed

energy generation opportunity for those who have on-site biogas-fired CHP, or a new opportunity for

WRRFs that do not have anaerobic digesters or where installation of a CHP is not cost-effective.

Energy from Biogas

Biogas, or anaerobic digester gas, is a byproduct of anaerobic digestion and contains 60 to 65%

methane. Biogas can be recovered to generate electricity and heat for on-site use. Typical CHP

technologies are internal combustion engines, microturbines, gas turbines, and fuel cells. Alternatively,

the biogas can be used directly as boiler fuel for the production of heat. Specific digesters and biogas

parameters as well as the impact of CHP on other treatment systems, cost of electricity, and the

potential for air regulations should be considered to assess the feasibility of installing a CHP system. This

practice is widely accepted and has been employed for years by WRRFs throughout New York State, the

United States, and the world.

More recent applications of biogas recovery include scrubbing the biogas of contaminants and CO

2

to

obtain a gas that is relatively pure methane and meets the quality standards of pipeline natural gas that

can be accepted by the gas utility. This renewable natural gas could also be used for vehicle fuel.

Energy from Photovoltaic Systems

Solar or photovoltaic (PV) systems are seeing widespread installation throughout New York State’s

residential, commercial, industrial, institutional and municipal sectors. Modest growth has been seen in

the installation of PV systems at WRRFs, but greater opportunity remains. PV can be particularly

attractive because it does not rely upon or interfere with the WRRFs processes, but rather, takes

advantage of large unused spaces such as building roofs, tank covers, or relatively flat, sun-exposed land

in between structures or within buffer lands surround utility assets. Costs for PV systems have

decreased through the years, making this renewable energy option more cost-effective. The use of

alternative ownership structures (e.g., land leases with power purchase agreements) can be used to

help capitalize upon available tax credits and other exemptions that may have little to no value to a tax

exempt entity like a wastewater utility, but provide value to private developers who can potentially pass

along a portion of the savings to the utility in the form of lower power purchase rates. It is important to

recognize that power purchase agreements often last 15 years or longer. So, thoughtful location of PV

resources is needed to avoid encroaching upon existing infrastructure or limiting additional expansion

that may be needed to meet treatment requirements over the duration of the PV system’s useful life.

Energy from Wind

Wind turbines can be installed at WRRFs to generate power from wind, operating up to 24 hours per day

in areas with naturally occurring consistent winds. The location for a wind turbine needs to be

14

unobstructed and away from human or vehicle traffic and outside of any flight paths. While the

footprint of wind turbines is substantially less than that for the same capacity of PV, most wind turbines

have substantial visual effects because of their height. Accordingly, if a wind turbine is considered, it is

important that stakeholders within the surrounding area are engaged in the siting of the project. Like

PV, the use of a power purchase agreement with a third-party private developer may allow a utility to

more effectively realize tax benefits offered by distributed renewable generation. Also, like PV, siting

requires thoughtful planning and long-term needs should be considered.

2.2 Basic Steps Involved in Building an Energy Program

This section outlines an eight-step approach to developing an effective energy management program.

Step 1: Establish Organizational Commitment via Strategic Energy Management (SEM)

Strategic Energy Management (SEM) applies the principles of continuous improvement to create a long-

term holistic approach to managing energy that fosters substantial long-term savings. SEM is a process

of evaluating existing energy management practices and implementing opportunities to optimize energy

use at a WRRF.

SEM begins with identifying an energy champion, an individual who’s passionate about reducing energy

consumption and will lead the implementation of SEM at the WRRF. The energy champion will develop

an energy team, a cross-functional group of WRRF management, technical, and operations staff who

have diverse knowledge of WRRF processes and practices and are authorized to make operational and

procedural changes. A strategically-selected and enthusiastic team is critical to the success of SEM, as is

utility management support. The basic components of SEM are as follows:

Measuring and tracking energy use to help inform strategic business decisions

Driving managerial and corporate behavioral changes around energy

Developing mechanisms to track and evaluate energy optimization efforts

Visit NYSERDA’s website at nyserda.ny.gov/All-Programs/Programs/Strategic-Energy-Management for

additional information on Strategic Energy Management. In addition, visit www.aceee.org for

information on Strategic Energy Management via the website for the American Council for an Energy-

Efficient Economy.

15

Step 2: Develop Baseline Energy Use

Understanding where, why, and when energy is used is a critical component of sound energy

management. Studies have shown that the process of investigating energy use and improving energy

awareness among staff, may result in measurable energy efficiency gains (~ 3–5%). The following list

summarizes the actions required to develop an energy use baseline:

Gather basic information. One year of data should be analyzed at a minimum to identify

any seasonal patterns, but three or more years of data is ideal so that any trends or

anomalies can be identified. Data sources can include utility billing records, supervisory

control and data acquisition (SCADA) system records, O&M records, submetering or data

logging records, and equipment/motor lists with horsepower and load information.

Organize treatment processes by functional area. Identifying logical functional groups

makes performance measurement and benchmarking easier and will also facilitate planning

for separating energy loads to manage demand. Additionally, maintaining a treatment

process or system approach may also help to identify opportunities or potential conflicts

that are missed if equipment is considered on a standalone basis.

Evaluate energy bills and understand the energy rate structure. Many energy

management strategies are directly linked to the pricing of energy, and it is critical to

understand how the “energy rate structure” impacts energy costs, as well as what other

options are available. It can be helpful to reach out to the power utility (most larger

accounts are assigned a representative) or a consultant for this step.

Assess the connection between changes in hydraulic loading and energy use. Hydraulic

data (i.e., flow) should also be assembled to understand patterns of demand and

correlations between flow and energy use. Analyze data at several time frames to identify

diurnal patterns, seasonal patterns, and correlations between wet weather flows and

energy demand. Where available, energy use per pound of organics treated (e.g., BOD or

Total Kjeldahl Nitrogen (TKN)) can also be a very effective metric to assess performance and

identify trends.

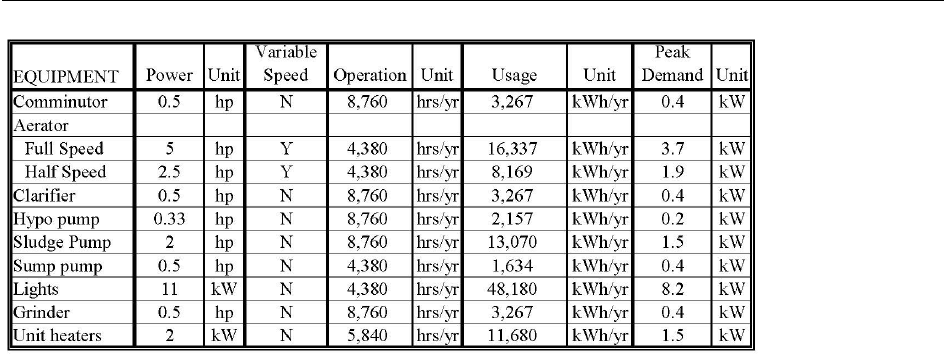

Build a basic model to organize data and capture energy use patterns. Typical models

used in this stage of the process can be created using a generic spreadsheet, or for larger

utilities it may be helpful to purchase specific software for organizing energy data. An

example of a basic spreadsheet model is provided in Appendix B. The level of modeling

sophistication can range from a basic motor list relating horsepower to energy demand to a

time-varying (dynamic) model that combines flow, process, and rate structure information

that predicts hourly demand and energy costs under various scenarios. The process of

modeling can help to identify what types of information are most helpful, the limitations on

currently available information, and what data needs to be gathered in the field. In

addition, an energy use model can be a valuable tool for testing theories, validating the

owner/manager’s understanding of energy use, calculating performance metrics, and

visualizing and communicating energy use patterns.

16

Create basic graphics and reports to communicate initial findings. Although this is an early

step in the process, it can produce some valuable insights that should be shared with a

wider audience than the energy management team.

Step 3: Evaluate the System and Collect Data

Whereas an energy use baseline is developed primarily from historical records, this step relies on

real-time data and input from operations/maintenance staff. The following list summarizes the actions

required to perform this step:

System walk-through. Verify equipment lists, operating status, and motor sizes for major

utility systems; begin with equipment/processes that have been identified as most energy

intensive during the baselining process.

Staff interviews. Build understanding of operating practices, maintenance practices and

history, regulatory and engineering limitations, operational priorities, and collect

suggestions for energy conservation opportunities.

Gather energy performance data. Fill gaps in the energy model with field data, which may

include direct measurements using a current meter, tracking average equipment run times

of motors throughout the day, or utilizing a more sophisticated sub-metering system or

temporary data logging to gather energy use data.

Benchmark energy performance. Identify useful performance measures and calculate

energy use in comparison with utility performance data. Examples include: kilowatt-hours

per million gallons treated, comparison of peak demand (kilowatts; kW) with peak pumping

rates (gallons per minute; gpm), or energy use measures based on contaminant removal

(kilowatt-hours per pound of BOD removed). Performance metrics can be compared

internally to historical data or engineering design criteria or can be used for external

benchmarking in comparison to similar facilities.

Update the energy use model. Make any improvements and/or corrections in the energy

use model using newly gathered field data and observations. This may include refining

assumptions about the load, set points, or time of use for various motors.

Step 4: Identify Energy Efficiency Opportunities

Energy efficiency opportunities can be any system change that helps achieve a stated energy

management goal. The initial goal is to identify as many opportunities as possible. Ideas for energy

efficiency opportunities can come from a variety of sources, including reference materials, success

stories from similar utilities, interviews with staff, consultant recommendations, or discussions with

energy providers.

17

Categorizing energy efficiency opportunities can help to organize a large amount of information into a

manageable format. For example, energy efficiency opportunities can be grouped by process area or by

the implementation approach used, such as the following:

Capital program or equipment replacement

Process change

Operational change

Automation or controls

Maintenance improvements

Business measures

Step 5: Implement No- and Low-Cost Opportunities

Some of the energy efficiency opportunities identified require no or a low-level of capital investment.

These opportunities are primarily oriented towards operational or cultural changes. Such opportunities

should be implemented first; and information about these strategies should be shared broadly.

Typically, no- and low-cost opportunities are found through the following suggestions:

Identify operations that are performed for no reason except because it’s always been

done that way and determine whether the routine performance still produces beneficial

outcomes.

Assess current treatment flows/loads to identify those that are much smaller than their

designed values and determine whether redundant/larger equipment/process tanks can be

taken offline.

Identify equipment that operates continually and ascertain whether it should be operated

intermittently.

Evaluate set points for automated controls and confirm they are still appropriate for actual

operating conditions or if daily or seasonal adjustment might provide energy savings.

Step 6: Prioritize Remaining Opportunities for Implementation

Once no- and low-cost opportunities have been identified, the remaining opportunities should be

prioritized based on meeting the WRRF’s energy management goals, economic viability, and ability to

implement without creating a high-level of risk or conflict. The prioritization process typically involves

some type of economic evaluation method such as payback period or life-cycle costs. Examples of

various economic evaluation methods are provided in Appendix C. The prioritization process may also

require site-specific evaluation criteria to evaluate benefits such as reduced risk of process failure or

improved operator safety.

18

Step 7: Develop an Integrated Capital/Energy Plan

Once energy efficiency opportunities are identified, the next step is planning for implementation. Similar

to a business plan, the implementation plan should clearly communicate the actions to be performed,

resources required, and outcomes anticipated from the projects. The following list summarizes the

actions required to complete the step:

List the candidate energy efficiency opportunities chosen for implementation and describe

the goals and objectives of the improvement.

Explain the resources needed, including a budget and financing plan.

Develop any specifications needed, including design criteria and procurement-related

documents.

Provide any changes in standard operating procedures and/or process control strategies.

Set the schedule for implementation, including milestones and gaining the necessary

regulatory approvals (if applicable). To the extent practicable, integrate larger energy

advancement measures as incremental add-ons to already planned capital projects rather

than creating multiple, smaller standalone capital projects. For smaller advancement

measures, consider using reserve funding or incorporating energy efficiency considerations

into traditional maintenance or procurement processes.

Step 8: Track and Report Success

Project success should be measured and documented at each phase of implementation with specific

performance metrics identified in advance of implementation. Documentation should include

information on impacts to process performance, operations and maintenance, and staff. Project success

must be communicated, especially to anyone involved in allocating funding for future projects and the

staff responsible for implementing the project. Communication of project success is often overlooked,

but it is critical to continuous improvement for the following reasons:

Encourages continuous adjustments until a process is optimized

Provides rationale for future decision making

Provides impetus to engage staff in continuous improvement

19

2.3 Constraints to Implementing an Energy Program

Most engineering decisions are made within the context of trade-offs or counterbalancing

constraints. Awareness and understanding of constraints are required for good energy planning

and decision-making.

Typical constraints on energy enhancements include the following:

Organizational constraints

Capital costs

Process reliability

Regulatory requirements and limits

O&M capabilities and non-energy O&M costs

Engineering constraints

Space availability

20

3 Energy Management Best Practices

The Energy Management Best Practices section of this guidebook is divided into four categories:

Renewable Distributed Generation

Organizational Energy Management

Treatment Process Energy Management

Building Systems Energy Management

Renewable Distributed Generation Best Practices describe practices for generating on-site energy to

reduce a WRRF’s reliance on grid-supplied power. In addition to generation of on-site power from

photovoltaic or wind systems, one unique aspect of the wastewater sector is the potential for on-site

electrical and thermal energy generation using anaerobic digester gas, a by-product of the anaerobic

sludge digestion process. Additionally, for some WRRFs the deployment of hydroelectric generation may

also be feasible.

Organizational Energy Management Best Practices describe management/planning practices applicable

to the overall facility. General approaches to develop an energy plan, educate facility personnel, and

manage electric bills are included in this section.

Treatment Process Energy Management Best Practices describe design and/or operations practices

applicable to wastewater treatment and collection systems. Best practices for optimizing pumps,

aeration systems, and solids handling processes are included in this section.

Building Systems Energy Management Best Practices describe design and/or operations practices

applicable to managing building system energy use. HVAC and lighting systems generally provide the

most opportunities for building-related energy efficiency improvements.

Each Best Practice can be used as a stand-alone document. Best Practices applicable to similar

processes are referenced under the “Additional Information” sections in the following tables.

As a supplemental NYSERDA resource, visit

nyserda.ny.gov/About/Publications/Research-and-

Development-Technical-Reports/Water-and-Wastewater-Technical-Reports for technical reports

on wastewater.

21

3.1 Renewable Distributed Generation Best Practices

R1—Generate Energy from Biosolids

Best Practice

Biogas produced by anaerobic digesters (AD) can be used as a fuel to generate

electricity via combined heat and power (CHP) systems (e.g., reciprocating engines,

microturbines, combustion turbines, fuel cells). The thermal energy generated by

CHP systems can often be recovered and used to meet digester heat loads and/or

for space heating. Alternatively, biogas can be used directly as boiler fuel; or

processed and injected into the natural gas pipeline; or used to fuel fleet vehicles.

Additional Information

WW 34—Optimize Anaerobic Digester Performance, R2—Increase Energy

Generation with Co-Digestion of Source-separated Organics.

Primary Area/Process

Anaerobic sludge digestion.

Productivity Impact

For existing AD systems, gas piping should also exist; therefore, relatively minimal

impact is expected during installation of a CHP system. If construction of new AD

system is required, impacts to operations could be significant.

Economic Benefit

Biogas-to-electricity systems are typically cost-effective options for WRRFs having an

average influent flow greater than 5 mgd with, or planning to install, AD systems.

Biogas-to-electricity systems may also be feasible for smaller WRRFs, if import of

feedstocks or consolidation of solids handling operations with other WRRFs is

possible (see R2). For smaller WRRFs with existing AD systems, processed biogas

may also be injected into the pipeline or used to fuel fleet vehicles.

Energy Savings

A common assumption made for AD systems is that for each 4.4 mgd of typical

strength municipal influent treated, the quantity of biogas produced will generate

approximately 100 kW of electricity and 12.5 MMBtu of thermal energy. When used

in boilers, biogas typically provides 550 to 650 Btu per scfm.

Applications and Limitations

The moisture content and concentration of hydrogen sulfide (H

2

S) in digester gas

influences both the economic and technical feasibility of a CHP system. High H

2

S

concentrations result in engine corrosion; in which case it may be necessary to

install gas scrubbers. Most CHP system suppliers claim that concentrations higher

than 1000 ppm would necessitate the installation of a gas scrubber. Other trace

compounds, such as siloxanes, can also cause deleterious effects to combustion

devices and should also be removed through gas treatment.

Practical Notes

Reciprocating engines are appropriate for most WRRFs. Microturbines and fuel cells

are typically smaller capacity; multiple units can be installed to increase capacity.

Microturbines are particularly relevant where emissions are a concern. Combustion

turbines can be used for larger capacity systems (greater than 1 MW. For larger

WRRFs with existing incinerators or biogas-fired steam systems, steam turbines are

a viable technology. Organic Rankine Cycle systems can be also be used to generate

electricity via waste heat from treatment process or primary generating systems.

Other Benefits

Beneficial use of biogas eliminates venting/flaring, which emit greenhouse gases.

Stage of Acceptance

Combined heat and power systems are gaining popularity in the wastewater sector.

22

R2—Increase Energy Generation with Co-Digestion of Source-Separated Organics

Best Practice

Co-digestion of sludge with other high-strength organic wastes (e.g., restaurant

grease, vegetable/fruit processing waste, municipally-derived food scraps) can

significantly increase biogas production. Co-digestion also maximizes use of AD

system capacity and may create a revenue stream for the WRRF.

Additional Information

R1—Generate Energy from Biosolids

Primary Area/Process

Anaerobic sludge digestion.

Productivity Impact

High-strength organic wastes are high in volatile fatty acids, which rapidly convert to

biogas. Co-digestion with high-strength wastes results in increased biogas

production. Increased sludge viscosity, due to increased concentration of total

solids, may impact the efficiency of mixing and pumping operations. Co-digestion of

FOG may result in the formation of a scum layer if not effectively mixed. Foaming or

other process upsets could result, depending on the characteristics of the added

feedstock. Waste receiving facilities may need to be to be built. Thickening,

dewatering, and disposal will also be needed to manage the increase in solids.

Economic Benefit

Receipt of high-strength wastes may generate revenue via collection of tipping fees

and additional power generation due to increased biogas production. Diversion of

FOG from collection systems may reduce maintenance costs.

Energy Savings

By diverting high-strength wastes directly to an AD system, secondary system

energy use should not be impacted. Depending on available digester capacity and

volume of high-strength waste added, increased biogas production can support

transition of the WRRF to net zero energy. Larger volume of solids may create

economies of scale that make upgrade to more energy efficient technologies viable.

Applications and Limitations

Construction of additional facilities, such as a waste receiving station, mixed

equalization tank, pretreatment or pre-processing facilities, or pumping, may be

require. If improperly stored, grease or dairy waste may generate odors.

Operational changes may be needed to handle additional solids (i.e., increased

duration of intermittent dewatering operations). Digester mixing capacity should be

evaluated before embarking on a co-digestion project.

Practical Notes

Source-separated wastes may be contaminated by inert debris (e.g., rocks,

silverware, plastic wrappers). Pre-consumer waste often has less debris and

unanticipated contamination. High-strength waste should be introduced slowly to a

healthy AD system to avoid process upset. New wastes should be fully characterized

before added to an AD system. Pilot testing may be warranted to avoid unforeseen

operational problems. Impacts to downstream solids handling processes, existing

solids disposal methods, and wet stream processes needed to treat side streams

associated with the digestion and dewatering processes should be fully understood.

Other Benefits

Diversion of source-separated wastes and FOG from landfills and collection systems.

Increased production of biogas that can be used for electrical generation, as a fuel

for thermal systems or vehicles, or injected into the natural gas pipeline.

Stage of Acceptance

Co-digestion has been successfully proven at full-scale.

23

R 3—Install Wind Generation System

Best Practice

Sited correctly, the installation of one or more wind turbines can provide a reliable,

albeit intermittent, source of renewable electricity generation. Coupled with

electricity storage, wind generation can be relied upon to provide a stable source of

renewable electricity that is independent of the other treatment operations

occurring at a WRRF.

Additional Information

None

Primary Area/Process

Wind generation is not directly associated with a given process or area. Typically

wind generation is most applicable when installed in large open areas on the WRRF

property or satellite properties that are owned by the wastewater utility or

municipality.

Productivity Impact

No impact on treatment processes when sited correctly. Some disturbance of plant

operations may occur during construction. Maintenance and upkeep of wind

turbines is likely outside of the normal skill set of WRRF operations and

maintenance staff.

Economic Benefit

Electricity generated by one or more wind turbines would be more cost-effective

than grid-supplied electricity, reducing a WRRF’s electricity costs.

Energy Savings

Electricity generated by the wind turbine(s) can be used to offset grid-supplied

electricity with a source of renewable distributed generation.

Applications and Limitations

The opportunity for wind generation varies significantly dependent upon electric

utility and State. A number of options are available to acquire renewable electricity

ranging from on-bill purchase of renewable energy through a WRRF’s existing

electric utility to on-site generation to entering into a direct third-party power

purchase agreement with or without an equity stake in the wind generation assets.

Practical Notes

Construction for large-scale wind generation requires substantial land space to

maintain setbacks from adjacent properties and, because of visual effects and

technical aspects of wind generation (noise and vibration, height, potential wildlife

impacts, and shadow flicker) may require significant public engagement and

permitting prior to construction. Tax credits and depreciation approaches that can

enhance the financial viability of a wind generation project may not be available to

tax-exempt entities, making Power Purchase Agreements with a third-party taxable

entity potentially more financially attractive for either on-site or off-site wind

generation facilities. For WRRFs that own substantial off-site land to support land

application activities, wind generation may offer a means to provide additional

benefit with the same property. Wind turbines and farming activities are able to

effectively co-exist.

Other Benefits

Electricity generation using a renewable resource like wind reduces greenhouse gas

emissions associated with electricity usage at a WRRF.

Stage of Acceptance

A number of WRRFs utilize wind generation (on and off site) to meet a portion of

their electricity needs. Wind generation as a technology is widely accepted and has

a proven track-record of successful operation.

24

R 4—Install Solar Photovoltaic Generation System

Best Practice

The installation of a solar photovoltaic (PV) electricity system can provide a reliable,

albeit intermittent, source of renewable electricity generation. Coupled with

electricity storage, PV generation can be relied upon to provide a stable source of

renewable electricity that is independent of the other treatment operations

occurring at a WRRF.

Additional Information

None

Primary Area/Process

PV generation is not directly associated with a given process or area. Large-scale

solar systems will typically be installed in large open areas on the WRRF property or

satellite properties that are owned by the wastewater utility or municipality. Smaller

scale solar systems can be constructed on existing roofs, as canopies over tanks or

parking, or as small, rack-mounted arrays throughout a WRRF site.

Productivity Impact

No impact on treatment processes when sited correctly. Some disturbance of plant

operations may occur during construction. Maintenance and upkeep of solar arrays

is likely outside of the normal skill set of WRRF operations and maintenance staff.

Economic Benefit

Electricity generated by one or more solar arrays would be more cost-effective than

grid-supplied electricity, reducing a WRRF’s electricity costs.

Energy Savings

Electricity generated by the solar array(s) can be used to offset grid-supplied

electricity with a source of renewable distributed generation.

Applications and Limitations

The opportunity for PV generation varies significantly dependent upon electric

utility and State. A number of options are available to acquire renewable electricity

ranging from on-bill purchase of renewable energy through a WRRF’s existing

electric utility to on-site generation to entering into a direct third-party power

purchase agreement with or without an equity stake in the PV generation assets.

Practical Notes

Construction of large-scale PV generation requires substantial land space to

accommodate the solar array and to maintain setbacks from adjacent properties.

Tax credits and depreciation approaches that can improve the financial viability of a

PV generation project may not be available to tax-exempt entities, making Power

Purchase Agreements with a third-party taxable entity potentially more financially

attractive for either on-site or off-site solar generation facilities. For WRRFs that

own substantial off-site land to support land application activities, PV generation

may offer a means to provide additional benefit with the same property by

constructing solar arrays on the less useable portions of the property. If solar arrays

are constructed on rooftops, be sure to consider the structural integrity and

longevity of the roof system. When PV systems are constructed over tanks or near

building exhausts, consider potential impacts of gases and vapors that may be

present.

Other Benefits

Electricity generation using a renewable resource like solar reduces greenhouse gas

emissions associated with electricity usage at a WRRF.

Stage of Acceptance

A number of WRRFs utilize PV generation (on and off site) to meet a portion of their

electricity needs. Solar generation as a technology is widely accepted and has a

proven track-record of successful operation.

25

3.2 Organizational Energy Management Best Practices

O 1—Facility Energy Assessments

Best Practice

An annual energy survey should be performed annually to assess opportunities for

energy efficiency. The survey should include all energy consuming processes.

Additional Information

None

Primary Area/Process

This practice should be completed for the entire facility, with emphasis on the

major energy using processes (i.e., pumping, aeration, solids management).

Productivity Impact

There may be short-term disturbances during implementation of opportunities.

Economic Benefit

Payback period varies depending on the complexity of the modifications and any

required capital investment.

Energy Savings

Energy savings vary depending on the existing equipment and the opportunities

identified. Savings typically range from 10 to 50% of the total system energy

consumption. Several projects have resulted in energy savings of as much as 65%.

Applications and Limitations

None

Practical Notes

Energy can be saved at every facility, regardless of treatment process, age, or size.

Other Benefits

May result in overall operational improvements as WRRF strives for additional

savings.

Stage of Acceptance

Acceptance of the value of energy assessments is growing. The acceptance varies

depending on opportunity (i.e., technology, practice).

Resources

The EPA offers the Portfolio Manager tool for benchmarking WRRFs, an interactive

web-based system that allows WRRFs to track and assess energy consumption and

carbon footprint. The tool is appropriate for primary, secondary, and advanced

treatment plants with or without nutrient removal.; and is applicable to WRRFs

having design flows of at least 0.6 mgd. After inputting the following information,

the tool produces an energy use score for the facility, which is relative to the scores

of a national population of WRRFs. The score is expressed on a scale of 1 to 100.

• 12 consecutive months of energy data

• Average influent flow rate

• Plant design flow rate

• Average influent biological oxygen demand (BOD5)

• Average effluent biological oxygen demand (BOD5)

• Presence of fixed film trickle filtration process

• Presence of nutrient removal process

The tool can be accessed through the following link:

http://www.energystar.gov/index.cfm?c=eligibility.bus_portfoliomanager_eligibility

26

O 2—Real Time Energy Monitoring

Best Practice

An accurate, real-time energy monitoring system permits the collection and analysis

of 15-minute energy data for each treatment process and pump installation. This

support tool enables utility staff and management to establish energy use reduction

goals and monitor/verify demand consumption.

Additional Information

None

Primary Area/Process

This technology can be applied to all process treatment units and is most beneficial

to high-energy users. High-energy users may include large facilities and/or facilities

that utilize an inordinate amount of energy or demand per unit of water conveyed

and treated.

Productivity Impact

No impact on a facility’s capability to meet treatment limits.

Economic Benefit

Payback depends on the cost of the monitoring system and on the system’s

adjustment capability.

Energy Savings

The achievable range of energy savings is typically 5 to 20% where energy efficiency

is viewed as a daily performance goal.

Applications and Limitations

Each site must be individually assessed to identify which processes can benefit the

most from monitoring.

Practical Notes

The most common barrier to implementation is acquiring management approval

and commitment for the capital expenditure. Be sure to include the potential

savings from energy management in payback calculations. This practice has been

suggested in benchmark studies.

Other Benefits

Monitoring also supports other functions, such as maintenance and the

identification of failing equipment.

Stage of Acceptance

This concept is well known but not widely practiced since it is usually not necessary

for meeting system performance goals (effluent limits).

27

O 3—Energy Education for Facility Personnel

Best Practice

All wastewater system personnel should understand the relationship between

energy efficiency and facility operations. Information can be found in various

publications, including this handbook and through training sessions offered through

organizations such as NYSERDA.

Additional Information

None

Primary Area/Process

This practice focuses on personnel, especially those who make both long- and

short-term decisions that affect energy use (including elected officials). All parties

involved in the operation of a wastewater conveyance and treatment facility can

benefit from understanding their system’s energy use.

Productivity Impact

None

Economic Benefit

There is no direct return on investment for this practice. The return will be a

function of actual process changes made in response to recommendations.

Energy Savings

The energy savings for this practice vary substantially depending on what measures

are implemented.

Applications and Limitations

None

Practical Notes

It is useful to establish an annual schedule for energy training to keep facility

management and personnel up to date on available technology and management

practices.

Other Benefits

Staff members and colleagues within the industry typically share and discuss the

information they gain from attending education classes and reading publications.

Stage of Acceptance

Education and training are common and widely accepted throughout the industry.

28

O 4—Comprehensive Planning Before Design

Best Practice

Clearly define utility goals and objectives and set the design criteria for system

improvements. Incorporate all appropriate energy efficiency best practices into

capital and operations enhancement plans. This helps the utility address the critical

needs of the future system and optimizes capital and operating budgets.

Additional Information

None

Primary Area/Process

All components of wastewater treatment systems.

Productivity Impact

None

Economic Benefit

Payback varies by facility and by project, depending on the energy benefits and

costs of alternative designs and operations. Payback may vary from a few months to

several years.

Energy Savings

Future energy savings are derived from the incorporation of energy efficiency

practices in the capital and operations improvement plans.

Applications and Limitations

There are no limitations on this practice because comprehensive planning should

occur prior to project development.

Practical Notes

Proactive and open communications promote the success of capital and operations

improvement planning, including energy management planning. Aggregating energy

efficiency measures into a capital enhancement project and justifying them in the

aggregate, helps avoid lost opportunities for future energy savings. Energy saving

improvements should be evaluated on a life-cycle cost basis.

Other Benefits

Well-conceived and planned projects result in the highest value to the utility.

Stage of Acceptance

Increasingly, utilities are seeing the value of energy management. Its acceptance is

growing, especially as a means to stretch limited budgets.

29

O 5—Design Flexibility for Today and Tomorrow

Best Practice

Operation, administration, and management personnel need to be involved with

the planning and design of any improvements and/or expansions to their system.

Take into account any significant anticipated changes when designing

enhancements or expansions that have the flexibility to serve both current and

future system needs.

Additional Information

None

Primary Area/Process

All components of wastewater systems.

Productivity Impact

Impact should be negligible.

Economic Benefit

The selected design of any improvements or expansions should reflect the best

quality for the most reasonable cost. The simple payback for installing smaller

operating units and storage that can follow current system demand—compared

with a larger, single unit operating at reduced capacity—is usually one to five years.