AESTHETIC ASSEMBLY - THE ART TO ATTRACTIVE BONDING

By Miranda Marcus

Dukane Intelligent Assembly Solutions

Abstract

After carefully molding a beautiful product, nothing is

worse than seeing it destroyed during assembly. Every

joining process is capable of causing marking, flash,

particulate, damage to appendages, or other aesthetic

defects. However, with proper part design and processing,

a finished weld can be imperceptible or even a cosmetic

asset. The art to attractive bonding is specific to each

process or type of product. Whether processing parts

through ultrasonic, spin, vibration, hot plate, laser welding

or thermal staking, methods do exist to improve the

appearance of the overall product after bonding.

Introduction

Welding is a common necessity for a wide variety of

industries, including automotive, medical, electronics, and

consumer products. Whether there are components that

must be securely enclosed or the part geometry is too

complex to be processed in one piece, a secondary joining

step is often required.

A wide variety of products must have aesthetic welds,

or bonds. Packaging, especially clamshells, are probably

the most prominent example. Some other demanding

cosmetic applications are vehicle headlamps and taillights,

spoilers, battery enclosures, medical devices, toys,

dishware and utensils, electronics housings, facemasks,

fencing, furniture, and filters. For these products, and

many others, melt flow must be contained, flash or

particulate eliminated, tool marks prevented, and any other

part damage eradicated.

The methods for preserving cosmetics are as varied as

the welding processes available. Each assembly process

can produce its' own variety of decorative debacle.

Fortunately, for each potential aesthetic issue, there is a

solution.

Ultrasonic Welding

Ultrasonic welding uses piezo-electric ceramics that

convert electrical current into mechanical motion. High

frequency (15 kHz up to 90 kHz) vibrations are transmitted

through the plastic part to the joint where intermolecular

stress and strain cause melting of the surface of both parts,

and welding. Ultrasonic welding is used for a wide variety

of applications including clamshells, electronics housings,

medical applications, and fabric welding.

Joint Design

One of the most common cosmetic defects that result

from ultrasonic welding is flash; melted material that is

pushed out of the joint at the weld interface. In addition to

being unsightly, this flash can also be a functional defect in

certain applications. For example, air or water filter

housings usually cannot have flash internally.

Fortunately, flash can be easily avoided through

proper joint design. Generally, in production, there is

balance between weld strength and amount of flash. In

order to get greater strength, more collapse of the joint is

required, and more flash is produced. Simply adding a

flash trap to the part design, however, can allow sufficient

strength with no flash. Figure 1 shows some common

ultrasonic joints that can effectively hide flash and produce

a strong weld.

Figure 1: Ultrasonic Joints that Hide Flash

De-Gating

A second common defect with ultrasonic welding is

de-gating of small features in the assembly during the

weld. Because ultrasonics depends on high frequency

vibration of the parts, there is a chance for cracks to form

in areas with sharp corners or small cross-sectional areas.

Sometimes these cracks are so severe that small features

can be complete sheared off, or de-gated.

There are two main ways to prevent this type of

damage. Either increase the radii or cross-section of the

troubled area, or decrease the amplitude of the process.

However, reducing amplitude often has a negative impact

on the weld, as it essentially reduces the energy available

to weld the parts. Therefore, whenever possible, it is best

to eliminate small or fragile features when ultrasonic

welding will be used.

\

Surface Marking

When welding textured parts, there is a strong

possibility that the ultrasonic horn will mar the contact

surface. On textured surfaces, there may be shiny places

where the texture has been removed during welding. To

prevent this occurrence, simply put a layer of thin film

between the part and the horn. Figure 2 shows an example

of this type of cosmetic flaw.

Figure 2: Ultrasonic Welding can cause damage to the

parts texture.

Marking can also occur when the horn leaves a residue

on the part, see Figure 3. This is most often seen with

aluminum horns or with titanium horns that are welding

white parts. Using chrome plated aluminum horns is the

best way to prevent this type of problem.

Figure 3: Ultrasonic welding with an aluminum horn can

leave residue on the part.

Film & Fabric

As mentioned in the introduction, clamshell packaging

is one of the biggest areas where cosmetic assembly is

required. Ultrasonic welding is one of the processes most

often used for such applications. A wide range of weld

patterns have been developed to improve the appearance of

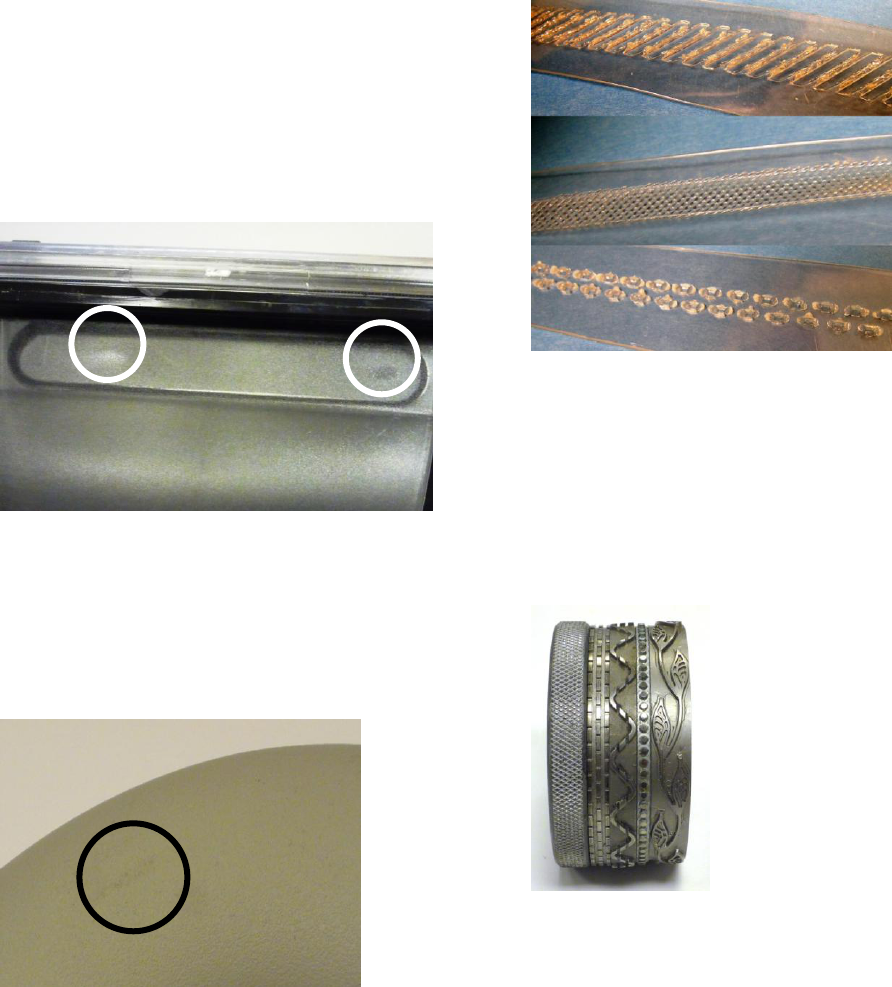

such welds. Figure 4 shows some common welding

patterns used for clamshells.

Figure 4: Examples of patterns used to weld clamshells

These same patterns can also be used for welding of

fabrics, as is often done for shower curtains, plastic bed

sheets, or even clothing. In fact, fabrics can be welded

using ultrasonics, very similarly to how they can be sewn,

using a rotating anvil under a stationary horn that is

operated by a foot pedal. An even wider range of attractive

patterns can be used for fabric welding; some are shown in

Figure 5 below.

Figure 5: Patterns used to weld film or fabric

Spin Welding

Another common welding process is spin welding. In

this process, one of the parts is held stationary, and the

other is spun at high revolutions per minute to generate

frictional heat at the circular joint. While spinning, the

parts are pressed together to form a weld. Spin welding is

often used to join pipes, insulated cups or bowls, and filter

housings, among others.

Joint Design

The biggest drawback, cosmetically, to spin welding is

that it generates a significant amount of flash. Unlike

ultrasonic welding, the parts are moving during the weld

process, meaning that the melt layer is also in motion.

Subsequently, more melt must be generated to ensure good

contact between the parts and a strong weld. Figure 6

shows an example of the type of flash generated during

spin welding.

Figure 6: Spin weld flash

Therefore, for every application where aesthetics is a

concern, the part should be designed to hide that melted

material, some weld joints that can hide flash are shown in

Figure 7. With out-of-round parts, however, it is often not

possible to contain the flash simply by using a different

joint design. In these instances, a secondary flash removal

step is required.

Figure 7: Spin weld joint designs that can hide flash

while providing a strong weld.

Particulate

In addition to solid pieces of displaced material, spin

welding tends to generate particulate (tiny particles of

plastic dust). Most times, this can be blown out after

welding, but sometimes it cannot be present at all (as with

medical or food industry applications). Reducing the

rotational spin welding speed reduces the generation of

particulate. Additionally, soft materials like polypropylene

tend to produce much more particulate during welding, as

shown in Figure 8.

Figure 8: Spin welding particulate

Tooling Marks

Like most other welding processes, there is the

possibility of leaving tooling marks on the parts.

Typically, this occurs on the upper part when it is not

securely held in place using designed driving features.

Tooling marks occur when the upper part slips in the tool.

When the fixture is made of urethane, this can cause black

marks on the parts. When it is made from stainless steel or

aluminum, it can leave gouges in the parts, see Figure 9.

Figure 9: Spin welding tooling marks

To avoid this type of marking, it is essential to provide

driving features on the part itself. A "driving feature" is

simply some type of protrusion or depression on the upper

part upon which the upper tool can apply rotational force.

In addition, the parts should have relatively consistent

external dimensions.

Vibration Welding

Vibration welding is one of the most often used

welding processes for large parts, such as vehicle

headlamps and taillights, glove boxes, intake manifolds,

fencing, and even furniture. In this process, one part is

held stationary while the other is vibrated horizontally on

top of it at low frequency (120 Hz - 240 Hz) and high

amplitude. During this vibration, the upper part is also

pressed down on to the lower part to create the weld.

Joint Design

Vibration welding depends on the movement of large

amounts of melted material to generate a weld. Therefore,

for this process as well, the joint design is critical for flash

containment. With the proper design, a strong flash free

weld can be achieved consistently. Figure 10 diagrams

some joint designs that can produce a strong weld with no

flash.

Figure 10: Vibration joint design diagrams

De-Gating

As with ultrasonic welding, the movement of the parts

during vibration weld can cause de-gating of small

features. The high amplitude used in vibration welding

causes excess stress on large projecting features. De-

gating is especially likely to occur when the base of the

feature has a small cross-sectional area or sharp corners.

Tooling Marks

Vibration welding is similar to spin welding in that

driving features on the part are required to prevent tooling

marks. In the absence of such features, a knurl pattern may

be used to grip the part. The use of a knurl, however, will

cause abrasions on the part, as shown in Figure 11.

Figure 11: Vibration welding tools often use knurling to

grip the parts.

If such marking is not acceptable a urethane upper

tool combined can sometimes be used to prevent scratches

on the part. Often, a vacuum must be used with urethane

tooling to provide sufficient holding force. Whatever

tooling material is used, the parts must still be kept as

dimensionally consistent as possible.

Hot Plate Welding

In hot plate welding, the two parts to be joined are

pressed against or brought into close proximity of a heated

surface to generate a melt layer, then pressed against each

other to complete the weld. In this style of welding, the

joint may be contoured quite extensively and strong

hermetic welds are generally achievable. Nothing can be

captured inside the parts, however, as any internal

components would be damaged by the hot plate. Hot plate

welding is often used for large pipes or tanks.

Joint Design

Although hot plate welding generates a lot of flash, it

is the most controlled, good-looking flash of any weld

process. The melted material pushed of the joint when the

two parts are pressed together forms a very nice rounded

line that can almost look as if it was designed to be there,

this can be seen in Figure 12. However, if the double line

of melt does not suit the application at hand, it can be

hidden with a change of joint design.

Figure 12: Hot plate flash can look very controlled and

nice

Out-Gassing

One of the unique potential cosmetic issues with hot

plate welding is out-gassing. When plastic is heated, it

emits gasses that can discolor the parts when they are

welded, especially on metalized surfaces. The effects of

out-gassing are identified in Figure 13. This can be

eliminated by applying a vacuum to one of the parts to

extract the fumes before they can cause any discoloration

or degradation.

Figure 13: Hot plate out-gassing

Warping

Due to the high heat input used in hot plate welding,

the parts can be warped during welding. The best way to

prevent this is to use thicker part walls. Excess warping

can also be avoided by using vacuums and clamping in the

tooling to keep the parts in the correct shape during the

weld.

Laser Welding

One of the newest polymer joining processes is laser

welding and is growing in popularity, particularly for

medical applications. This assembly method uses a

focused laser beam to heat the weld joint. The two parts

are simultaneously pressed together to create the weld.

Laser welds are known for being very clean; flash and

particulate free. Laser welding never causes de-gating of

features and generally never causes warping. Still, for

some components, there is potential for cosmetic defects.

Surface Degradation

If improperly set up, there is a chance that surface

degradation will occur during welding. This happens if the

top part absorbs too much of the laser energy or if the

bottom part absorbs too little. This can be somewhat

adjusted for by changing the focal point of the laser, but it

is best avoided by choosing the materials with good laser

welding properties at the outset.

Burning

The greatest potential for aesthetic flaws in an

established process is marring from dirt or dust that is

burned by the laser during the weld. Any dust in the path

of the laser will absorb the weld energy and cause a

disparity in the weld. To prevent this, it is important to

maintain the cleanliness of the lens and the weld joint.

Burning can also appear in the process set-up phase as

over-welding. An example of over-welding by laser is

shown in Figure 14. To resolve this issue, decrease

wattage to lessen the laser energy or increase the travel

speed of the laser. In some systems, over-welding can be

eliminated by adjusting the focus point of the laser so that

it is further from the part.

Figure 14: Laser over-welding causes burns at the

joint

Thermal Staking

Thermal staking is a method of mechanically bonding

two parts by melting and reforming one of the parts to

contain the other. Most often, a post on the part with the

lower melting temperature is melted and formed into a

dome shape to hold in the second part, similar to a rivet.

Thermal staking is frequently used to contain circuit boards

or to replace screws on consumer products.

Stake Design

The most common cause of unattractive stakes is

improper post or tool detail design. It is vital that the

staking detail has the same volume as the unformed post.

If it is too small, excess material can be pushed out around

the base of the stake. If it is too larger, the detail will be

only half-formed and uneven in appearance. Figure 15

shows two of the most common staking detail design.

Figure 15: Thermal staking design diagrams

Sticking

Even if the post and staking detail are properly

designed, however, there is a chance that the formed dome

can be marred if the melted material sticks to the thermal

tool. This is especially common with soft materials, like

polyethylene. Happily, it can easily be avoided through

temperature modulation and the use of post cool. Figure

16 shows the type of stringy wisps of material that can be

left behind when the parts sticks to the thermal tool.

Dome

Rosette

Figure 16: Thermal sticking

Conclusion

If an application must be beautiful, then it is best to

begin considering the assembly method early in the design

process. Most of the common cosmetic defects can be

avoided with proper part design. Planning for aesthetic

assembly in these early stages will help allow a widened

processing window in production and reduce reject rate.

However, if a part is already in production without having

planned for the welding process, do not panic. There is

plenty that can be done to prevent unsightly flash, marking,

or other defects. Figures 17-20 show some examples of

attractive welds.

Figure 17: A well-designed ultrasonic joint results in a

strong, flash free, weld

Figure 18: An attractive spin weld, free of tool marking,

particulate, and flash

Figure 19: A properly designed vibration joint shows no

flash

Figure 20: Laser welding is one of the cleanest joining

methods available. Photo courtesy of Leister Corporation.

Figure 21: A nicely formed thermal stake