User's Guide

QTouch® Modular Library Peripheral Touch Controller

User's Guide

Description

The Microchip QTouch

®

Peripheral Touch Controller (PTC) offers built-in hardware for capacitive touch

measurement on sensors that function as buttons, sliders, and wheels. The PTC supports both mutual

and self-capacitance measurement without the need for any external component. It offers superb

sensitivity and noise tolerance, as well as self-calibration, and minimizes the sensitivity tuning effort by

the user.

The PTC is intended for autonomously performing capacitive touch sensor measurements. The external

capacitive touch sensor is typically formed on a PCB, and the sensor electrodes are connected to the

analog charge integrator of the PTC using the device I/O pins. The PTC supports mutual capacitance

sensors organized as capacitive touch matrices in different X-Y configurations, including Indium Tin Oxide

(ITO) sensor grids. In Mutual Capacitance mode, the PTC requires one pin per X-line (drive line) and one

pin per Y-line (sense line). In Self-Capacitance mode, the PTC requires only one pin with a Y-line driver

for each self-capacitance sensor.

Features

• Implements Low-Power, High-Sensitivity, Environmentally Robust Capacitive Touch Buttons

• Supports Mutual Capacitance and Self-Capacitance Sensing

• Up to 32 Buttons in Self-Capacitance mode

• Up to 256 Buttons in Mutual Capacitance mode

• Supports Lumped Mode Configuration

• One Pin Per Electrode - No External Components

• Load Compensating Charge Sensing

• Parasitic Capacitance Compensation for Mutual Capacitance mode

• Adjustable Gain for Superior Sensitivity

• Zero Drift Over the Temperature and V

DD

Range

• No Need for Temperature or V

DD

Compensation

• Hardware Noise Filtering and Noise Signal De-Synchronization for High Conducted Immunity

• Atmel Start QTouch Configurator Support – Wizard Guided Touch Project Creation

Product Support

For assistance related to QTouch capacitive touch sensing software libraries and related issues, contact

your local microchip sales representative or visit https://www.microchip.com/support/.

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 1

Table of Contents

Description.......................................................................................................................1

Features.......................................................................................................................... 1

Product Support...............................................................................................................1

1. Introduction................................................................................................................5

2. Capacitive Touch Measurement................................................................................ 6

2.1. Self-Capacitance.......................................................................................................................... 6

2.2. Mutual Capacitance......................................................................................................................7

3. Touch Sensors.........................................................................................................10

3.1. Buttons....................................................................................................................................... 10

3.2. Proximity Sensor........................................................................................................................ 10

3.3. Lumped Sensor..........................................................................................................................10

3.4. Linear Sensors........................................................................................................................... 11

3.5. 2D Position Sensors................................................................................................................... 11

3.6. Mix and Match............................................................................................................................ 11

4. PTC......................................................................................................................... 12

4.1. Overview.................................................................................................................................... 12

4.2. Self-Capacitance........................................................................................................................ 12

4.3. Mutual Capacitance....................................................................................................................12

5. QTouch Modular Library.......................................................................................... 14

5.1. Introduction.................................................................................................................................14

5.2. QTouch Library Modules............................................................................................................ 14

5.3. Module Naming Conventions..................................................................................................... 14

5.4. QTouch Library Application Interface......................................................................................... 16

5.5. Application Flow......................................................................................................................... 17

5.6. MISRA Compliance.................................................................................................................... 17

6. Acquisition Module.................................................................................................. 19

6.1. Overview.................................................................................................................................... 19

6.2. Interface..................................................................................................................................... 19

6.3. Functional Description................................................................................................................19

6.4. Data Structures.......................................................................................................................... 20

7. Frequency Hop Module........................................................................................... 26

7.1. Overview.................................................................................................................................... 26

7.2. Interface..................................................................................................................................... 26

7.3. Functional Description................................................................................................................27

7.4. Data Structures.......................................................................................................................... 27

User's Guide

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 2

8. Frequency Hop Auto-tune Module...........................................................................30

8.1. Overview.................................................................................................................................... 30

8.2. Interface..................................................................................................................................... 30

8.3. Functional Description................................................................................................................31

8.4. Data Structures.......................................................................................................................... 33

9. Touch Key Module................................................................................................... 34

9.1. Overview.................................................................................................................................... 34

9.2. Interface..................................................................................................................................... 34

9.3. Functional Description................................................................................................................35

9.4. Data Structures.......................................................................................................................... 36

10. Scroller Module........................................................................................................39

10.1. Overview.................................................................................................................................... 39

10.2. Interface..................................................................................................................................... 39

10.3. Functional Description................................................................................................................40

10.4. Data Structures.......................................................................................................................... 41

11. Binding Layer Module..............................................................................................44

11.1. Overview.................................................................................................................................... 44

11.2. Interface..................................................................................................................................... 44

11.3. Functional Description................................................................................................................45

11.4. Data Structures.......................................................................................................................... 47

12. Building Applications Using Atmel START...............................................................49

12.1. Working With KIT Example Projects.......................................................................................... 49

12.2. Creating User-Board Projects.................................................................................................... 50

12.3. Import Project Using Atmel Studio............................................................................................. 62

12.4. Import Project Using IAR

™

Workbench......................................................................................65

13. Using Data Visualizer with QTouch

®

Applications................................................... 72

13.1. Overview.................................................................................................................................... 72

13.2. Datastreamer Module.................................................................................................................72

13.3. Debugging Using Data Visualizer...............................................................................................73

14. Tuning Procedure.................................................................................................... 78

14.1. Tuning for Noise Performance....................................................................................................78

14.2. Tuning the Slider/Wheel Sensor.................................................................................................83

15. Known Issues.......................................................................................................... 86

16. Appendix A - Revision History.................................................................................87

17. Appendix B - Acquisition Module API Reference.................................................... 88

18. Appendix C - Frequency Hop Module API Reference.............................................90

19. Appendix D - Frequency Hop Auto-tune Module API Reference............................ 91

User's Guide

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 3

20. Appendix E - Touch Key Module API Reference.....................................................92

21. Appendix F - Scroller Module API Reference..........................................................93

22. Appendix G - Binding Layer Module API Reference............................................... 94

23. Appendix H - Device Support.................................................................................. 95

The Microchip Web Site................................................................................................ 96

Customer Change Notification Service..........................................................................96

Customer Support......................................................................................................... 96

Microchip Devices Code Protection Feature................................................................. 96

Legal Notice...................................................................................................................97

Trademarks................................................................................................................... 97

Quality Management System Certified by DNV.............................................................98

Worldwide Sales and Service........................................................................................99

User's Guide

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 4

1. Introduction

The QTouch

®

Modular Library (QTML) provides the touch sensing functionality of a QTouch Library under

a modular architecture. By dividing the library into functional units, it is possible for an application

developer to include only those modules which provide functionality relevant to the target application,

thereby saving both device memory and processing time.

User's Guide

Introduction

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 5

2. Capacitive Touch Measurement

The QTouch Modular Library supports PTC measurement of self-capacitance and mutual capacitance

touch sensors on a selection of AVR

®

and SAM

®

microcontrollers.

In all current capacitive touch measurement methods, one of two basic functional approaches is

implemented: self-capacitance or mutual capacitance.

2.1 Self-Capacitance

Self-capacitance refers to a capacitive measurement using a single sensor electrode to measure the

apparent capacitance between the electrode and the DC ground of the touch sensor MCU circuit.

At power-on or Reset, a baseline measurement of the capacitance is recorded and assumed to be the

‘Out Of Touch’ capacitance. Reference capacitance is the combination of Cp in parallel to the series pair

Cg and Cx.

When a touch contact is applied, the capacitance is increased by the introduction of a parallel path to

Earth, via the series combination of Ct and Ch. The increase is compared to the touch threshold, and if

exceeded, the sensor is indicated to be ‘In Touch’.

Note: Cx, the human body capacitance, varies by person and surroundings and is typically in the order

of 100 pF to 200 pF. The touch contact Ct, however, is more consistent and much smaller at typically 1 pF

User's Guide

Capacitive Touch Measurement

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 6

to 5 pF, depending primarily on the design and construction of the touch sensor and secondly on the size

of the finger used to activate the sensor.

As the dominant component in a pair of series capacitors is the smaller one, in this case Ct, a well-

designed and tuned sensor shows very consistent sensitivity to touch contact with little dependence on

the user.

2.2 Mutual Capacitance

Mutual capacitance refers to a capacitive measurement using a pair of sensor electrodes to measure the

apparent capacitance between them. Typically, one electrode acts as the Driver (X), while the other is the

receiver (Y). Each physical location where an X electrode transfers charge to a Y electrode is a sensor

node, and this is the location of touch sensitivity.

User's Guide

Capacitive Touch Measurement

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 7

As with self-capacitance, a baseline measurement of the capacitance is recorded and assumed to be the

‘Out Of Touch’ capacitance. Reference capacitance is the apparent capacitance between the X electrode

and the Y electrode. Unlike self-capacitance, the reference capacitance does not depend on an earth

return.

Interaction between a mutual capacitance sensor and the human body is more complex. It may be

modeled by considering two separate touch contacts to the X and Y electrodes, where each is

capacitively coupled to the body, resistively connected to each other inside the body and capacitively

coupled to earth via the human body capacitance.

A touch contact has two competing effects:

• The introduction of a conductive plate (finger) to both X and Y electrodes increases the capacitance

between X and Y. This occurs if any conductive part is placed over the sensor

User's Guide

Capacitive Touch Measurement

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 8

• The addition of another capacitance (Ch + Cg) at the XY node provides an alternative path for the

energy emitted by X electrode, reducing the amount of charge accumulated on the sensor. This

effect is manifested as an apparent reduction in the XY capacitance. This occurs only if the body of

material connected to the conductive part has a significant self-capacitance.

When a real touch contact is placed, the second (reducing) effect is much greater than the first

(increasing) effect, and so a touch contact on a mutual capacitance sensor is indicated by an apparent

reduction in sensor capacitance.

This apparent change in capacitance (delta) is compared to the configured touch threshold, and if it

exceeds the threshold then the sensor is deemed to be in detect.

User's Guide

Capacitive Touch Measurement

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 9

3. Touch Sensors

Capacitive sensors may be implemented to simply detect contact as a button replacement, or functionally

extended to provide a relative measurement of distance (proximity), 1D position (slider or wheel), 2D

position (QTouch Surface), or 3D position (QTouch Surface with proximity).

In each case, the modular library detects a touch contact by a change in capacitance exceeding a pre-

configured threshold. Once a contact has been confirmed, the various post-processing modules use the

calculated touch delta to interpolate amongst neighboring sensors and calculate the location of the touch

position or relative proximity.

3.1 Buttons

The simplest implementation of a capacitive sensor is a button, where the sensor consists of a single

node (one electrode for self-capacitance, one pair of electrodes for mutual capacitance) and is interpreted

as a binary state; In Detect or Out of Detect.

3.2 Proximity Sensor

An extension of the button is a proximity sensor. A single sensor node is monitored for a change in

capacitance exceeding a pre-configured threshold. In the same way as the button, the sensor is

considered to be ‘In Detect’ when that threshold is exceeded. Once in detect, a relative measurement of

the contact distance is made by scaling the touch delta between two thresholds, the initial ‘Detect’

threshold and a second ‘Full Contact’ threshold.

Note: As the proximity sensor relies on the capacitive load of a distant object, the ‘apparent distance’ to

the contact will depend on the shape and size of the contact.

i.e., an open hand in proximity at 10 cm will ‘appear’ closer than an extended finger at 10cm, as it has a

larger influence on capacitance due to a larger surface area at the same distance.

Capacitance (C) is proportional to Area (A) and inversely proportional to distance (d).

3.3 Lumped Sensor

A Lumped sensor is implemented as a combination of multiple sense lines (self-capacitance

measurement) or multiple drive and sense lines (mutual capacitance measurement) to act as one single

sensor. This provides the application developer with greater flexibility in the touch sensor implementation.

• Improve the touch sensor responsiveness by reducing the number of measurements and therefore,

the time required for initial touch detection

• Fast position resolution by binary search

• Improved moisture rejection through ‘All but one’ key lumping in a touch button application

• Provide wake-on-touch functionality on any key (up to maximum capacitance limits) with

significantly lower power consumption as only one sensor measurement is required for all keys

• Dual purpose sensor electrodes – e.g., individual keys may be lumped together to form a proximity

sensor

Touch detection on a lumped sensor is implemented in the same way as a single node touch button.

User's Guide

Touch Sensors

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 10

3.4 Linear Sensors

A linear sensor utilizes the touch delta of two or more adjacent sensor nodes arranged in a row to

calculate the position of a touch contact along that row. The sensor layout is designed and the threshold

configured in such a way that a contact anywhere along the sensor will cause:

1. A touch delta exceeding the threshold on at least one sensor node. The node with the

strongest touch delta is determined to be the center node of the touch contact and identified the

approximate location of the touch contact.

2. Some touch delta on neighbouring nodes, used for position interpolation between nodes.

The relative delta on the nodes to the left and right of the center node are used to adjust the

calculated touch position towards the side with the strongest delta.

A linear sensor may be formed into any physical shape, with or without a wrap-around from the last

sensor to the first. A sensor with wrap-around is configured as a ‘Wheel’, while one without is configured

as a ‘Slider’. In the case of the wheel, a touch contact centered on the 1

st

key uses the last key for ‘left’

interpolation and vice-versa while the slider option implements a dead band at the ends.

3.5 2D Position Sensors

Where a linear sensor is physically implemented as a line of keys, the same approach may be extended

to 2D position detection through a grid of keys. The keys are designed such that interpolation may be

made in either the vertical or horizontal direction, and multiple separate touch contacts may be

individually resolved in their interpolated positions.

3.6 Mix and Match

The QTouch Modular Library allows an unprecedented degree of combinations implementing different

sensor types and measurement technology, in many cases utilizing the same sensor electrodes in

multiple ways and within the same firmware application.

For example, a 2D position sensor using mutual capacitance key sensors may be lumped or partially

lumped in Mutual Capacitance mode to provide proximity measurements and the Y lines individually

measured in Self-Capacitance mode to improve moisture immunity.

User's Guide

Touch Sensors

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 11

4. PTC

4.1 Overview

The Microchip QTouch

®

Peripheral Touch Controller (PTC) offers built-in hardware for capacitive touch

measurement on sensors that function as buttons, sliders, and wheels. The PTC supports both mutual

and self-capacitance measurement without the need for any external components. It offers superb

sensitivity and noise tolerance, as well as self-calibration, and minimizes the sensitivity tuning effort by

the user.

The PTC is intended for autonomously performing capacitive touch sensor measurements. The external

capacitive touch sensor is typically formed on a PCB, and the sensor electrodes are connected to the

analog charge integrator of the PTC using the device I/O pins. The PTC supports mutual capacitance

sensors organized as capacitive touch matrices in different X-Y configurations, including Indium Tin Oxide

(ITO) sensor grids.

4.2 Self-Capacitance

In Self-Capacitance mode, the PTC requires only one pin with a Y-line driver for each self-capacitance

sensor.

Figure 4-1. Self-Capacitance PTC Measurement

4.3 Mutual Capacitance

In Mutual Capacitance mode, the PTC requires one pin per X-line (drive line) and one pin per Y-line

(sense line).

User's Guide

PTC

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 12

Figure 4-2. Mutual Capacitance PTC Measurement

User's Guide

PTC

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 13

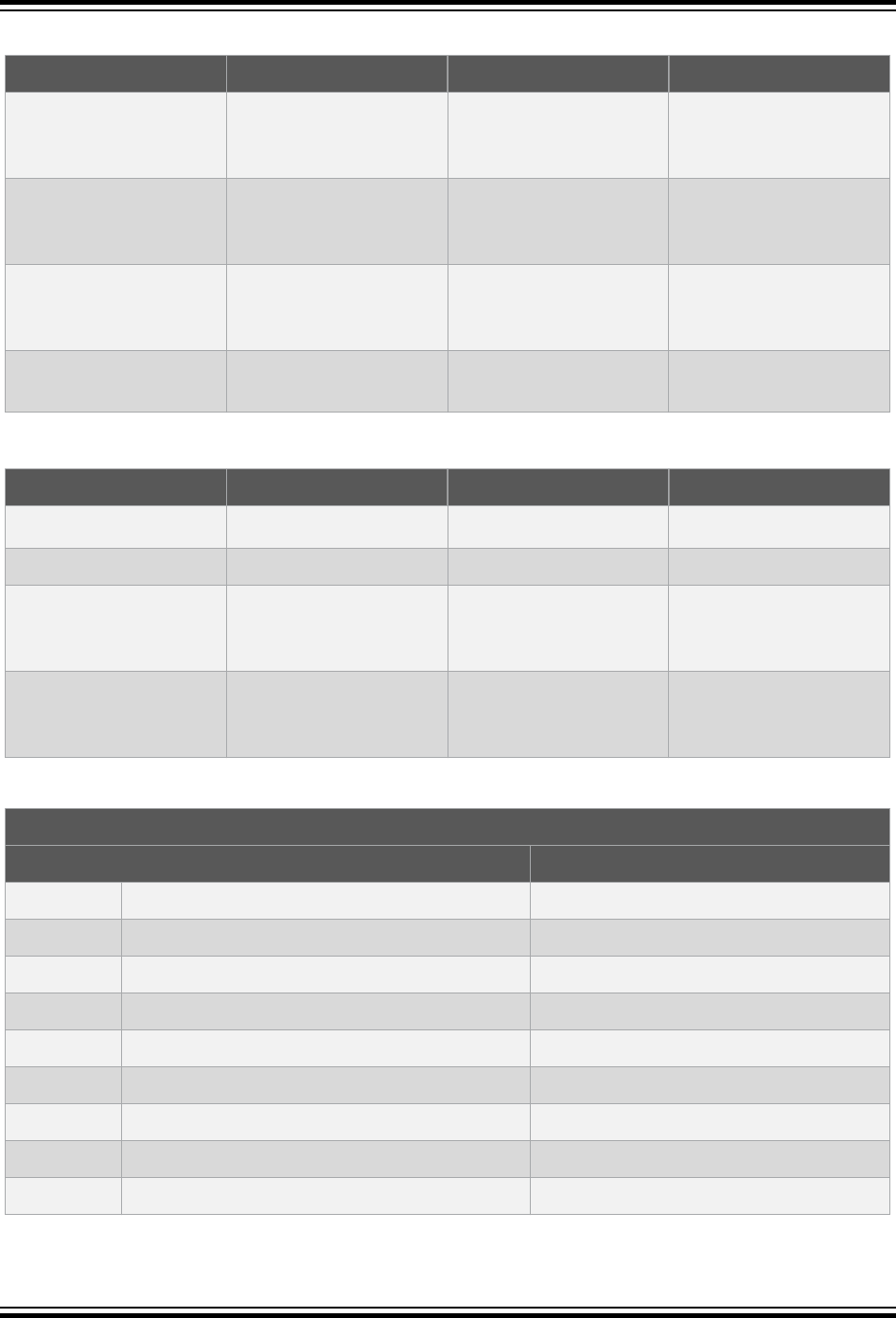

5. QTouch Modular Library

5.1 Introduction

The QTouch Modular Library provides the touch sensing functionality of a QTouch Library under the

redesigned modular architecture. By dividing the library into functional units, it is possible for an

application developer to include only those modules which provide functionality relevant to the target

application, thereby saving both device memory and processing time.

5.2 QTouch Library Modules

QTouch Library modules can be classified into three types based on the functionality as shown below.

5.3 Module Naming Conventions

The naming conventions followed on the QTouch Library modules are given below.

qtm _ <module_name_identifier> _ <device_architecture> _ <module_ID> .

<file extension>

qtm / libqtm

Acronym indicates QTouch module. All QTouch modules begin with

“qtm_” for easy identification.

User's Guide

QTouch Modular Library

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 14

For GCC modules, “lib” is prepended to the module name, thus it

would be “libqtm”.

module_name_identifier

acq – acquisition module with auto-tune

acq_runtime – acquisition module without auto-tune code

freq_hop – Frequency hop module

freq_hop_auto_tune – frequency hop with auto-tune module

device_architecture

cm0p – for all cortex M0+ post processing modules

cm4 – for all cortex M4F post processing modules

samd1x – samd10/d11 acquisition modules only

t81x – all modules of AVR tiny817 device families

t161x - all modules of AVR tiny1617 device families

t321x - all modules of AVR tiny3217 device families

m328pb - all modules of AVR mega328pb device

m324pb - all modules of AVR mega324pb device

saml21 - saml21 acquisition module only

saml22 - saml22 acquisition module only

samc21 - samc21 acquisition module only

samc20 - samc20 acquisition module only

samd21 - samd21 acquisition module only

samda1 - samda1 acquisition module only

samha1 - samha1 acquisition module only

samd20 - samd20 acquisition module only

module_id

Unique 16-bit identifier for each module

file_extension

.a – GCC modules of AVR and ARM

®

devices, IAR modules of ARM

devices

.r90 – IAR modules of all AVR modules

Table 5-1. Acquisition module of AVR mega328pb device

GCC module:

libqtm_acq_m328pb_0x0001.a

IAR module :

qtm_acq_m328pb_0x0001.r90

Touch keys processing module of SAMd10/d11 device

GCC module:

libqtm_touch_keys_cm0p_0x0002.a

IAR module :

qtm_touch_keys_cm0p_0x0002.a

User's Guide

QTouch Modular Library

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 15

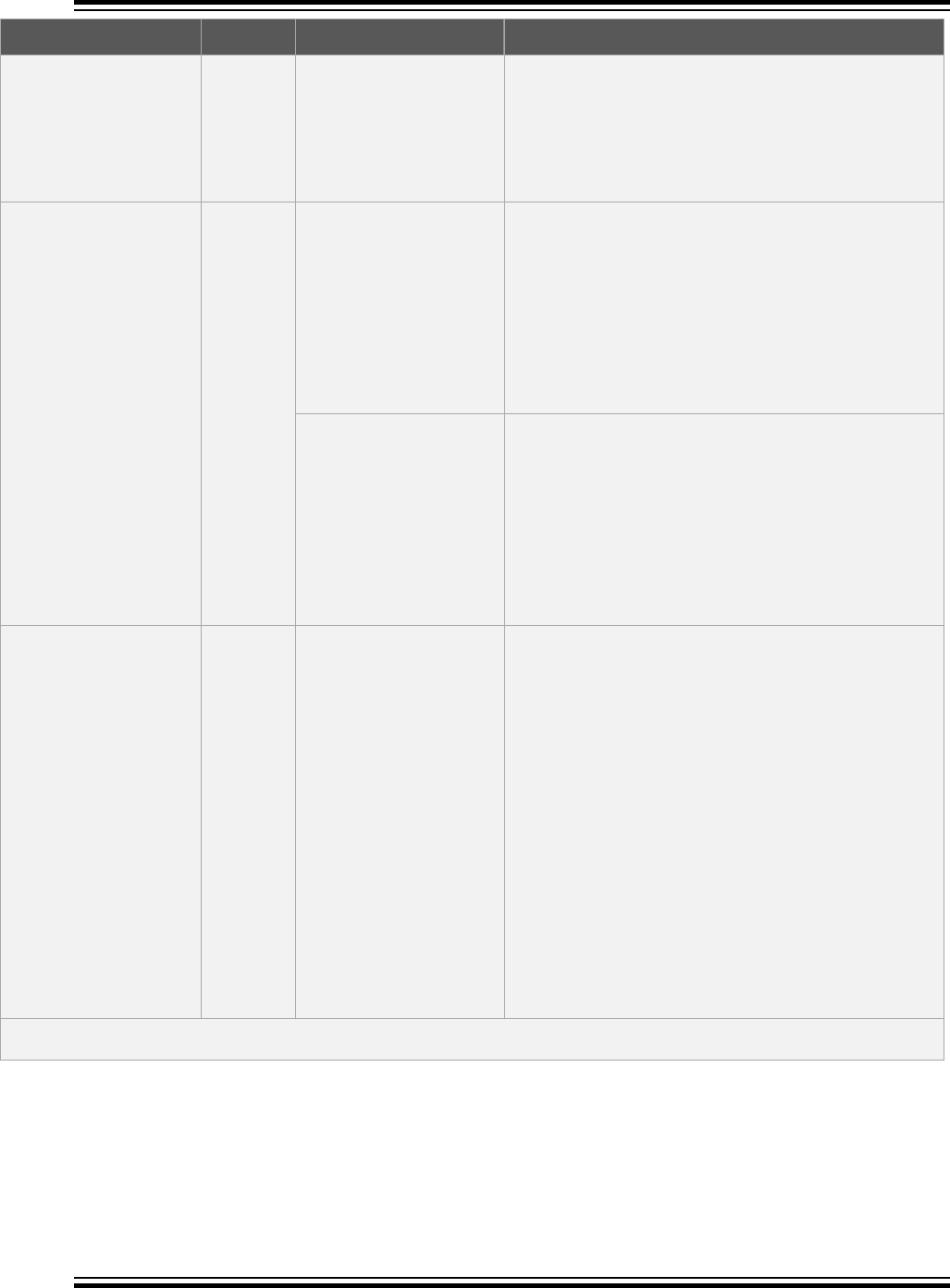

5.4 QTouch Library Application Interface

In addition to library modules, the various components that are required to build the complete touch

application are given below.

1. Module API files

2. Touch.c and Touch.h files

3. Common_components_api.h

4. Touch_api_ptc.h

5. Module reburst flag

6. Binding layer module

5.4.1 Module API files

The API for each module is defined in its associated header file. Dependencies between modules are

minimized and implemented at the application level. This allows for easy porting of application code from

one device to another – only the hardware dependent module configurations must be adjusted. The

acquisition auto-tune and acquisition manual tune modules have the same API file. All the other modules

have their own API file that needs to be linked to the user application.

5.4.2 Touch.c and Touch.h files

User options for each module are configured in application code, typically touch.h and touch.c, and

shared with the library module by pointer reference. Similarly, arrays are created in application code for

modules’ run-time data and provided to the module via a pointer.

Configurations may be modified on-the-fly by application code in between measurement sweeps of the

touch sensors. All runtime data is available to application code.

5.4.3 Common_components_api.h

The application requires structures and definitions common to all modules. The common definitions,

macros and the data structures are placed in the file “qtm_common_components_api.h”.

5.4.4 Touch_api_ptc.h

This file contains all the module API files included in the content and thus this single file is sufficient to be

included on the application source files wherever necessary.

5.4.5 Module Reburst Flag

Module configuration and functionality is unique to each module, but any module may require a repeated

measurement of specific sensors. In order to achieve this, a signal conditioning module may temporarily

change the acquisition configuration, e.g. to disable those sensors not requiring reburst.

This is indicated to the application by the implementation of a common ‘Status’ byte at the first location of

the signal conditioning group data structure. A ‘1’ in bit 7 indicates that the application should re-start

measurement on the sensor group without waiting for the measurement cycle timeout.

Figure 5-1. uint8_t qtm_xxx_status

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Re-burst

Module specific status flags

User's Guide

QTouch Modular Library

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 16

5.4.6 Binding Layer Module

The binding layer module provides easy interface of QTouch modules to the user application. The binding

layer binds all the configured modules in the appropriate sequence using minimal API functions. It takes

care of initialization of modules, synchronizes the calling procedures and handles the error statuses.

5.5 Application Flow

5.6 MISRA Compliance

QTouch Library modules source code is compliant with the ‘Required’ rule set of MISRA 2004, with the

following exceptions:

Table 5-2. AVR MCU Acquisition Modules and Exceptions:

Acquisition modules of Mega32xpb, Tiny81x, Tiny161x, Tiny321x devices

MISRA Rule Definition Remarks

1.1

All code shall conform to ISO 9899:1990

Programming languages – C, amended and

Compiler is configured to allow

extensions

User's Guide

QTouch Modular Library

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 17

Acquisition modules of Mega32xpb, Tiny81x, Tiny161x, Tiny321x devices

MISRA Rule Definition Remarks

corrected by ISO/IEC 9899/COR1:1995, ISO/IEC

9899/AMD1:1995, and ISO/IEC 9899/COR2:1996

8.5

There shall be no definitions of objects or

functions in a header file

Inline functions are used in the header

files

17.4

Array indexing shall be the only allowed form of

pointer arithmetic

Pointer of module data structures are

passed as parameter and individual

object data are fetched by iterating the

data structure as array index.

Table 5-3. AVR Postprocessing Modules & Exceptions:

Touch_key, binding layer, frequency hop auto tune, frequency hop, scroller

MISRA Rule Definition Remarks

17.4

Array indexing shall be the only

allowed form of pointer arithmetic

Pointer of module data structures are passed as

parameter and individual object data are fetched

by iterating the data structure as array index.

Table 5-4. ARM Acquisition Modules & Postprocessing Modules :

Modules

MISRA Rule Definition Remarks

1.1

All code shall conform to ISO 9899:1990

Programming languages – C, amended and

corrected by ISO/IEC 9899/COR1:1995, ISO/IEC

9899/AMD1:1995, and ISO/IEC 9899/COR2:1996

Compiler is configured to allow

extensions

17.4

Array indexing shall be the only allowed form of

pointer arithmetic

Pointer of module data structures are

passed as parameter and individual

object data are fetched by iterating the

data structure as array index.

User's Guide

QTouch Modular Library

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 18

6. Acquisition Module

6.1 Overview

The minimum requirement for a touch sensor application is an acquisition module, which implements all

hardware dependent operations for configuration and measurement of capacitive touch or proximity

sensors.

6.2 Interface

The data structure definitions and the API declarations are included in the API file

“qtm_acq_<device_id>_<module_id>_api.h”. The data structure covers all the configurations and

output data variables. This file should be included on the common api ‘touch_ptc_api.h’ file.

User

Application

Touch.h

Macros and

constants

Qtm_acq_<device_i

d>_<Module_id>_a

pi.h

Touch_api_ptc

.h

Acquisition

Module

common_

components_api.h

Touch.c

Global variables declaration

and initialization, Helper API

functions

6.3 Functional Description

Acquisition modules are target specific, each having a hardware configuration structure depending on the

touch sensing technology and method applied.

User's Guide

Acquisition Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 19

Features Implemented in this Acquisition Module

• Hardware calibration for sensor nodes

– Calibration of Prescaler/Resistor/Charge share delay to compensate for time constant of

sensor electrodes

– Calibration of internal compensation circuit to match sensor load

• Selfcap and mutual cap sensor touch measurement with normal sequencing

• Low-Power mode of automated scanning using Event System (currently not supported on Atmel

Start Configurator)

6.4 Data Structures

6.4.1 Configurations

The acquisition module implements all functionality required for making relative measurements of sensor

capacitance. This is the only module uniquely built for an individual device, as it must access and control

the pins used for touch sensor implementation.

As devices have different hardware features available, different configuration options are available on

each device. For most efficient use of system resources – ROM and RAM – different sensor configuration

structures are required.

However, where the same variable name is used within the structure, the functionality controlled by that

variable is identical. Any dependent function should utilize a reference to the variable, and NOT rely on a

reference to the structure and pointer arithmetic.

User's Guide

Acquisition Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 20

Acquisition Group Configuration

A reference by pointer to ‘&ptc_qtlib_acq_gen1.freq_option_select’ will always point to the

correct memory location, regardless of the device. However, any implementation based on pointer

arithmetic will require re-factoring if code is to be re-used from one device for another.

Parameter Size Range/Options Usage

num_sensor_nodes

16-bit 0 to 65535

The number of sensor nodes

configured in the group.

acq_sensor_type

8-bit

NODE_SELFCAP

NODE_MUTUAL

Defines the measurement method

applied to this group of nodes.

calib_option_select

1 byte

Bits 7:4

Calibration type:

CAL_AUTO_TUNE_NONE

CAL_AUTO_TUNE_RSEL

CAL_AUTO_TUNE_PRSC

CAL_AUTO_TUNE_CSD*

Calibration Type selects which

parameter should be automatically

tuned for optimal charge transfer.

Bits 3:0

Calibration type:

CAL_CHRG_2TAU

CAL_CHRG_3TAU

CAL_CHRG_4TAU

CAL_CHRG_5TAU

Calibration target applies a limit to the

charge transfer loss allowed, where a

higher setting of target ensures a

greater proportion of full charge is

transferred.

freq_option_select

1 byte

FREQ_SEL_0 to FREQ_SEL_15

Or FREQ_SEL_SPREAD

FREQ_SEL_0 to FREQ_SEL_15 inserts

a delay cycle between measurements

during oversampling, where 0 is the

shortest delay, 15 the longest.

FREQ_SEL_SPREAD varies this delay

from 0 to 15 in a sawtooth manner

during the oversampling set

PTC_interrupt_priority**

1 byte 1 to 3 Interrupt priority level for the PTC.

Note: * - Not available on all devices

** - Applicable for ARM cortex devices only

Node Configuration

Similarly, node configuration structures vary depending on which device is used.

• Number of X lines

• Number of Y lines

• Feature availability

User's Guide

Acquisition Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 21

Parameter Size Range/Options Usage

node_xmask

1/2/4

Bytes

(Bitfield)

Set the bit(s) at location(s) corresponding to X line

number(s).

Example:

X0 only = 0b00000001 = 0x01

X0 and X2 = 0b00000101 = 0x05

1 byte is used for devices with up to 8 “X” lines

2 bytes and 4 bytes are used for devices up to 16

and 32 “X” lines respectively

node_ymask

1/2/4

Bytes

(Bitfield)

Set the bit(s) at location(s) corresponding to Y line

number(s).

Example:

Y5 only = 0b00100000 = 0x20

Y1, Y2 and Y7 = 0b10000110 = 0x86

1 byte is used for devices with up to 8 “Y” lines

2 byte and 4 bytes are used for devices up to 16

and 32 “Y” lines respectively

node_csd*

1 byte 0 to 255

Number of delay cycles to ensure charging of

sensor node capacitances.

(Applicable for AVR

®

Tiny, Mega ARM

®

SAM E54,

SAMCx, SAML22 family only)

node_rsel_prsc

1 byte

Bits 7:4 = RSEL

RSEL_VAL_0

RSEL_VAL_3*

RSEL_VAL_6*

RSEL_VAL_20

RSEL_VAL_50

RSEL_VAL_75*

RSEL_VAL_100

RSEL_VAL_200*

Internal Y line series resistor selection

(75k and 200k are available on ARM SAM E54

family and SAML22)

Bits 3:0 = PRSC

PRSC_DIV_SEL_1

PRSC_DIV_SEL_2

PRSC_DIV_SEL_4

PRSC_DIV_SEL_8

Clock Prescaler

Acquisition clock is derived and scaled from CPU

Clock for AVR devices

(Prescalar values 16, 32, 64, 128 are available on

AVR Tiny, SAM E5x family, SAM D51)

User's Guide

Acquisition Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 22

Parameter Size Range/Options Usage

PRSC_DIV_SEL_16*

PRSC_DIV_SEL_32*

PRSC_DIV_SEL_64*

PRSC_DIV_SEL_128*

node_gain

1 byte

Bits 7:4 = Analog Gain

GAIN_1

GAIN_2

GAIN_4

GAIN_8

GAIN_16

Analog gain setting

Integration capacitor adjusted to control integrator

gain.

Bits 3:0 = Digital Gain

GAIN_1

GAIN_2

GAIN_4

GAIN_8

GAIN_16

Digital gain setting

Accumulated sum is scaled to Digital Gain.

node_oversampling

1 byte

FILTER_LEVEL_1

FILTER_LEVEL_2

FILTER_LEVEL_4

FILTER_LEVEL_8

FILTER_LEVEL_16

FILTER_LEVEL_32

FILTER_LEVEL_64

FILTER_LEVEL_128*

FILTER_LEVEL_256*

FILTER_LEVEL_512*

FILTER_LEVEL_1024*

Number of samples to accumulate for each

measurement.

Note: Oversampling must be configured to be

greater than or equal to digital gain for correct

operation.

(Higher filter level values > 64 are available only on

ARM SAM E54 family only)

Note: * - Not available on all devices

6.4.2 Status and Output Data

While different target hardware requires that the configuration structure for sensor nodes varies from one

device to another, all acquisition modules conform to a standard sensor node data structure. Processed

module output data are stored in this data structure during run-time.

The outputs/status information may be used by other post processing modules or by the application.

User's Guide

Acquisition Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 23

Parameter Size Range/Options Usage

node_acq_status

1 byte

Bit 7

Indicates node calibration error

NODE_CAL_ERROR

Bit 6 Rise Time calibration complete

Bit 5 -

Bit <4:2> (three bits)

Node calibration state

NODE_MEASURE

NODE_CC_CAL

NODE_PRSC_CAL

NODE_RSEL_CAL

NODE_CSD_CAL

Indicates whether a calibration is ongoing and its

current stage.

Calibration Request

Write to 1 to trigger calibration sequence on this

node.

(Reset to ‘0’ by module once actioned)

Enabled

Write to ‘1’ to enable this node for measurement

node_acq_signals

2 bytes

Most recent measurement for

this sensor node.

16-bit unsigned value

Accumulated and scaled as per

node_oversampling and

node_gain_digital settings.

node_comp_caps

2 bytes Hardware calibration data

Indicates the tuning of the compensation circuit

for this node.

Table 6-1. node_acq_status

Bit 7 6 5 4 3 2 1 0

Node

Calibration

Error

Rise time

calibration

complete

- Node State

Calibrate

request

Enabled

NODE_MEASURE

0

NODE_CC_CAL

1

NODE_PRSC_CAL

2

NODE_RSEL_CAL

3

NODE_CSD_CAL* 4

Note: * - CSD Calibration is not available on SAMD10/D11, SAMD2x, SAML21 devices.

User's Guide

Acquisition Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 24

Acquisition Library State

Table 6-2. touch_lib_state_t

TOUCH_STATE_NULL

0

TOUCH_STATE_INIT

1

TOUCH_STATE_READY

2

TOUCH_STATE_CALIBRATE

3

TOUCH_STATE_BUSY

4

Return Parameter

Table 6-3. touch_ret_t common return type, used by all QTML modules

TOUCH_SUCCESS

0

TOUCH_ACQ_INCOMPLETE

1

TOUCH_INVALID_INPUT_PARAM

2

TOUCH_INVALID_LIB_STATE

3

TOUCH_INVALID_POINTER

11

TOUCH_LIB_NODE_CAL_ERROR

14

Note: Other values are reserved for future use.

User's Guide

Acquisition Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 25

7. Frequency Hop Module

7.1 Overview

Frequency Hop module provides a way of filtering the noise during the sensor measurement by varying

the frequency of bursting the sensors. Module ID for frequency hop module is 0x0006 and the module

name is in the format given below.

GCC compiler:

libqtm_freq_hop_xxxxx_0x0006.a

IAR compiler (AVR MCU):

qtm_freq_hop_xxxxx_0x0006.r90

IAR compiler (ARM MCU):

qtm_freq_hop_xxxxx_0x0006.a

Note: “xxxxx” – string based on the device architecture that the module is built.

7.2 Interface

The data structure definitions and the API declarations are included in the API file

‘qtm_freq_hop_0x0006_api.h’. The data structure covers all the configurations and output data

variables. This file should be included on the common api ‘touch_ptc_api.h’ file.

User

Application

Touch.h

Macros and

constants

Qtm_freq_hop_

0x0006_api.h

Touch_api_

ptc.h

Frequency

Hop Module

common_

components_api.h

Touch.c

Global variables declaration

and initialization, Helper

API functions

The default values of configurations should be defined on the touch.c and touch.h files. Global

variables of the data structures have to be initialized in touch.c file and the reference of the structure has

to be used on the application files.

User's Guide

Frequency Hop Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 26

7.3 Functional Description

Frequency Hop module is interfaced between acquisition module and rest of post processing modules as

shown below.

Frequency Hop

Auto-Tune

Module

The Frequency Hop module applies a configurable cyclic frequency hopping algorithm, such that on each

measurement cycle a different sampling frequency is used. The module is initialized with predefined

frequencies which are set by cyclic order during the consecutive measurement cycles.

The measured raw signal values from the Acquisition module are then passed through “Median filter”.

Finally, the filtered value is stored back on the memory for further processing by the post processing

modules.

More number of frequencies provide effective filtering by processing more samples. However, this also

increases the buffer size used by the median filter and takes more number of measurement cycles to

report filtered value. So, the number of frequencies should be configured based on the RAM memory

available.

7.4 Data Structures

User's Guide

Frequency Hop Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 27

7.4.1 Configurations

Parameter Size Range/Options Usage

num_sensors

1 Byte 0-255

Number of sensors to

buffer data for median

filter

num_freqs

1 Byte 3-to-7

Number of frequencies

to cycle/depth of median

filter

*freq_option_selec

t

2/4 Bytes N/A

Pointer to acquisition

library frequency

selection parameter

*median_filter_fre

q

2/4 Bytes N/A

Pointer to array of

selected frequencies

7.4.2 Status and Output Data

Parameter Size Range/Options Usage

module_status

1 Byte N/A

Module Status – N/A

current_freq

1 Byte 0-to-15 Current frequency step

*filter_buffer

2/4 Bytes N/A

Pointer to the filter buffer

array for measured

signals

*qtm_acq_node_data

2/4 Bytes N/A

Pointer to the node data

structure of the

acquisition group

Table 7-1. List of Supported Frequencies

PTC Clock = 4 MHz

PTC frequency Delay Cycles Frequency (kHz)

0

FREQ_SEL_0

66.67

1

FREQ_SEL_1

62.5

2

FREQ_SEL_2

58.82

3

FREQ_SEL_3

55.56

4

FREQ_SEL_4

52.63

5

FREQ_SEL_5

50

6

FREQ_SEL_6

47.62

7

FREQ_SEL_7

45.45

8

FREQ_SEL_8

43.48

User's Guide

Frequency Hop Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 28

PTC Clock = 4 MHz

PTC frequency Delay Cycles Frequency (kHz)

9

FREQ_SEL_9

41.67

10

FREQ_SEL_10

40

11

FREQ_SEL_11

38.46

12

FREQ_SEL_12

37.04

13

FREQ_SEL_13

35.71

14

FREQ_SEL_14

34.48

15

FREQ_SEL_15

33.33

16

FREQ_SEL_SPREAD

Variable frequencies

User's Guide

Frequency Hop Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 29

8. Frequency Hop Auto-tune Module

8.1 Overview

The Frequency Hop auto-tune module is the super set of frequency hop module with additionally

providing noise monitoring and tuning the frequency according to the measured noise factor.

The Module ID for the Frequency Hop auto-tune module is ‘0x0004’ and the module name is in the format

given below.

GCC compiler :

libqtm_freq_hop_auto_xxxxx_0x0004.a

IAR compiler (AVR MCU) :

qtm_freq_hop_auto_xxxxx_0x0004.r90

IAR compiler (ARM MCU) :

qtm_freq_hop_auto_xxxxx_0x0004.a

Note: “xxxxx” – string based on the device architecture that the module is built.

8.2 Interface

The data structure definitions and the API declarations are included in the API file

‘qtm_freq_hop_auto_0x0004_api.h’. The data structure covers all the configurations and output

data variables. This file should be included on the common api touch_ptc_api.h file.

User's Guide

Frequency Hop Auto-tune Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 30

User

Application

Touch.h

Macros and

constants

Qtm_freq_ho

p_auto_0x00

04_api.h

Touch_api_

ptc.h

Frequency

Hop Auto

-tune Module

common_

components_api.h

Touch.c

Global variables declaration

and initialization, Helper API

functions

The default values of configurations should be defined on the touch.c and touch.h files. Global

variables of the data structures have to be initialized in touch.c file and the reference of the structure has

to be used on the application files.

8.3 Functional Description

The Frequency Hop auto-tune module is interfaced between the acquisition module and the rest of post

processing modules as shown below.

User's Guide

Frequency Hop Auto-tune Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 31

Frequency Hop

Auto-Tune

Module

The Frequency Hop auto-tune module applies a configurable cyclic frequency-hopping algorithm, such

that on each measurement cycle a different sampling frequency is used. A number of preconfigured

frequencies are implemented in turn during consecutive measurement cycles.

Where ‘n’ frequencies are included in the cycle, an ‘n’-point median filter is applied to the output data.

To perform auto-tuning, the signals measured on each sensor node are recorded for each selected

frequency. When one frequency shows greater variance than others, that frequency is removed from the

measurement sequence and replaced with another.

User's Guide

Frequency Hop Auto-tune Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 32

8.4 Data Structures

8.4.1 Configurations

Parameter Size

Range/

Options

Usage

num_sensors

1 Byte 0 – 255

Number of sensors to buffer data for median

filter

num_freqs

1 Byte 3-to-7

Number of frequencies to cycle/depth of

median filter

*freq_option_select

Pointer 2/4

Bytes

Pointer

Pointer to acquisition library frequency

selection parameter

*median_filter_freq

Pointer 2/4

Bytes

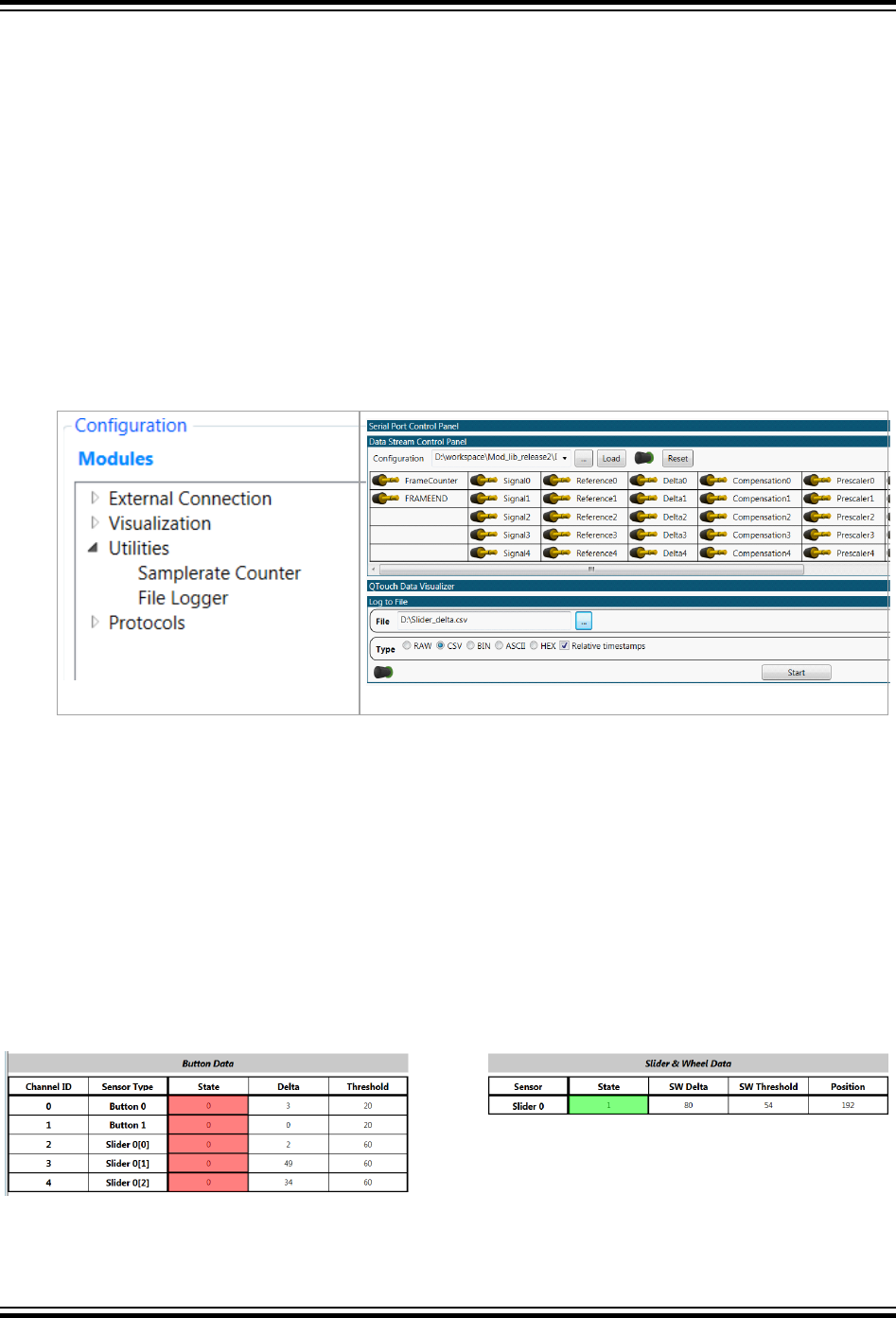

Pointer Pointer to array of selected frequencies

enable_freq_autotune

1 Byte 0 or 1

Disable (0) or Enable (1) automatic retuning

of hop frequencies

max_variance_limit

1 Byte 1-to-255

Signal variance required to trigger returning

of hop frequency

Autotune_count_in

1 Byte 1-to-255

Number of occurrences of

max_variance_limit to trigger retuning

of hop frequency

8.4.2 Status and Output Data

Parameter Size Range/Options Usage

module_status

1 Byte N/A Module Status – N/A

current_freq

1 Byte 0-to-15 Current frequency step

*filter_buffer

Pointer 2/4 Bytes Pointer

Pointer to the filter buffer array for

measured signals

*qtm_acq_node_data

Pointer 2/4 Bytes Pointer

Pointer to the node data structure of

the acquisition group

*freq_tune_count_ins

Pointer 2/4 Bytes Pointer

Pointing to the counter array to trigger

frequency change

User's Guide

Frequency Hop Auto-tune Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 33

9. Touch Key Module

9.1 Overview

Touch Key module implements functionality that can handle the key sensors also called as one

dimensional touch sensors. The module receives the raw output from the acquisition module, process

them and provide touch status of key sensors. The processing includes signal post-processing,

environmental drift, touch detection, touch state machine and timing management for the implementation

of application touch sensors. Reference touch sensor designs are provided to assist the users to evaluate

and design their custom sensor boards. The touch sensor board view and the sensor design of QT3

XPlained Pro sensor board are shown below.

QT3 Sensor Board Overlay

QT3 Sensor Board Design

Table 9-1. Module Format

GCC compiler :

libqtm_touch_key_xxxxx_0x0002.a

IAR compiler (AVR MCU) :

qtm_touch_key_xxxxx_0x0002.r90

IAR compiler (ARM MCU) :

qtm_touch_key_xxxxx_0x0002.a

9.2 Interface

The data structure definitions and the API declarations are included in the API file

‘qtm_touch_key_0x0002_api.h’. The data structure covers all the configurations and output data

variables. This file should be included on the common api touch_ptc_api.h file.

User's Guide

Touch Key Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 34

User

Application

Touch.h

Macros and

constants

Qtm_touch_key

_0x0002_api.h

Touch_api_

ptc.h

Touch Key

Module

common_

components_api.h

Touch.c

Global variables declaration

and initialization, Helper API

functions

9.3 Functional Description

The Touch Key module is responsible for the detection of a touch contact, where higher-level module(s)

carry out position interpolation, gesture recognition, contact tracking etc.

Features implemented in the touch key module:

• Timing management for detecting towards touch, away from touch

• Software calibration

– Reference Signal

– Reference Drift

• Touch Detection State Machine

User's Guide

Touch Key Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 35

9.4 Data Structures

9.4.1 Configurations

Table 9-2. Group Configuration

Parameter Size Range/Options Usage

num_key_sensors

2 Bytes 1-to-65535

Number of sensor keys in the

group

sensor_touch_di

1 Byte 0-to-255

Number of repeat measurements to

confirm touch detection

sensor_max_on_time

1 Byte

0 (Disabled), 1-

to-255

Number of timer periods with

sensor In Detect before automatic

‘recal’

sensor_anti_touch_di

1 Byte

0 (Disabled), 1-

to-255

Number of repeat measurements to

confirm anti-touch recalibration

required

sensor_anti_touch_recal_thr

1 Byte 0-to-5

Scale-down of touch threshold to

set anti-touch threshold.

0 = 100% Touch Threshold

1 = 50%

2 = 25%

3 = 12.5%

4 = 6.25%

User's Guide

Touch Key Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 36

Parameter Size Range/Options Usage

5 = Maximum Recalibration

sensor_touch_drift_rate

1 Byte

0 (Disabled), 1-

to-255

Number of timer periods to

countdown between towards touch

drifts

sensor_anti_touch_drift_rate

1 Byte

0 (Disabled), 1-

to-255

Number of timer periods to

countdown between away from

touch drifts

sensor_drift_hold_time

1 Byte

0 (Disabled), 1-

to-255

Number of timer periods to stop

drifting after touch event

sensor_reburst_mode

1 Byte

0 = None

1 = Unresolved

(Quick reburst)

2 = All

None – Reburst is never set,

measurements according to

application schedule.

Unresolved – Reburst is set, all

sensors suspended but those in

same AKS as the target sensor.

All – Reburst is set, no sensors are

suspended.

Table 9-3. Individual Sensor Configuration

Parameter Size Range/Options Usage

channel_threshold

1 Byte 0-to-255 Minimum signal delta indicating touch contact

channel_hysteresis

1 Byte 0 (50%)-to-4 (3.125%)

Reduction of touch threshold to de-bounce

when filtering out removed touch contact

channel_aks_group

1 Byte 0-to-255

Grouping of key sensors controlling

simultaneous touch detect.

9.4.2 Status and Output Data

Table 9-4. Group Data

Parameter Size Range/Options Usage

qtm_keys_status

1 Byte

Bit 7: Reburst required

Bit 6-1: Reserved

Bit 0: Touch Detection

Indicates the

current state of

the Touch Key

Group

acq_group_timestamp

2 Bytes 0-to-65535

Timestamp of last

drift period

processed

dht_count_in

1 Byte

0-to-‘sensor_drift_hold_time’

Countdown to drift

hold release after

touch event

User's Guide

Touch Key Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 37

Parameter Size Range/Options Usage

tch_drift_count_in

1 Byte

0-to-‘sensor_touch_drift_rate’

Countdown to

next towards

touch drift period

antitch_drift_count_in

1 Byte

0-to-‘sensor_anti_touch_drift_rate’

Countdown to

next away from

touch drift period

Individual Key Sensor Data

The individual key sensor data is required by other post processing modules like Scroller. So, this data

structure definition is placed on the common_compoenents_api.h file.

Parameter Size Range/Options Usage

sensor_state

1 Byte Bitfield Touch key sensor state

sensor_state_counter

1 Byte 0-to-255

Number of repeat measurements to confirm

touch detection

*node_data_struct_ptr

2/4 Bytes Pointer Pointer to node data structure array

Channel_reference

2 Bytes 0-to-65535

Reference measurement, baseline for touch

detection

Table 9-5.

sensor_state

QTM_KEY_STATE_DISABLE

0x00

QTM_KEY_STATE_INIT

0x01

QTM_KEY_STATE_CAL

0x02

QTM_KEY_STATE_NO_DET

0x03

QTM_KEY_STATE_FILT_IN

0x04

QTM_KEY_STATE_DETECT

0x85

QTM_KEY_STATE_FILT_OUT

0x86

QTM_KEY_STATE_ANTI_TCH

0x07

QTM_KEY_STATE_SUSPEND

0x08

QTM_KEY_STATE_CAL_ERR

0x09

Note: Bit 7 (0x80u) is set in each state where the touch key sensor is ‘In Detect’

User's Guide

Touch Key Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 38

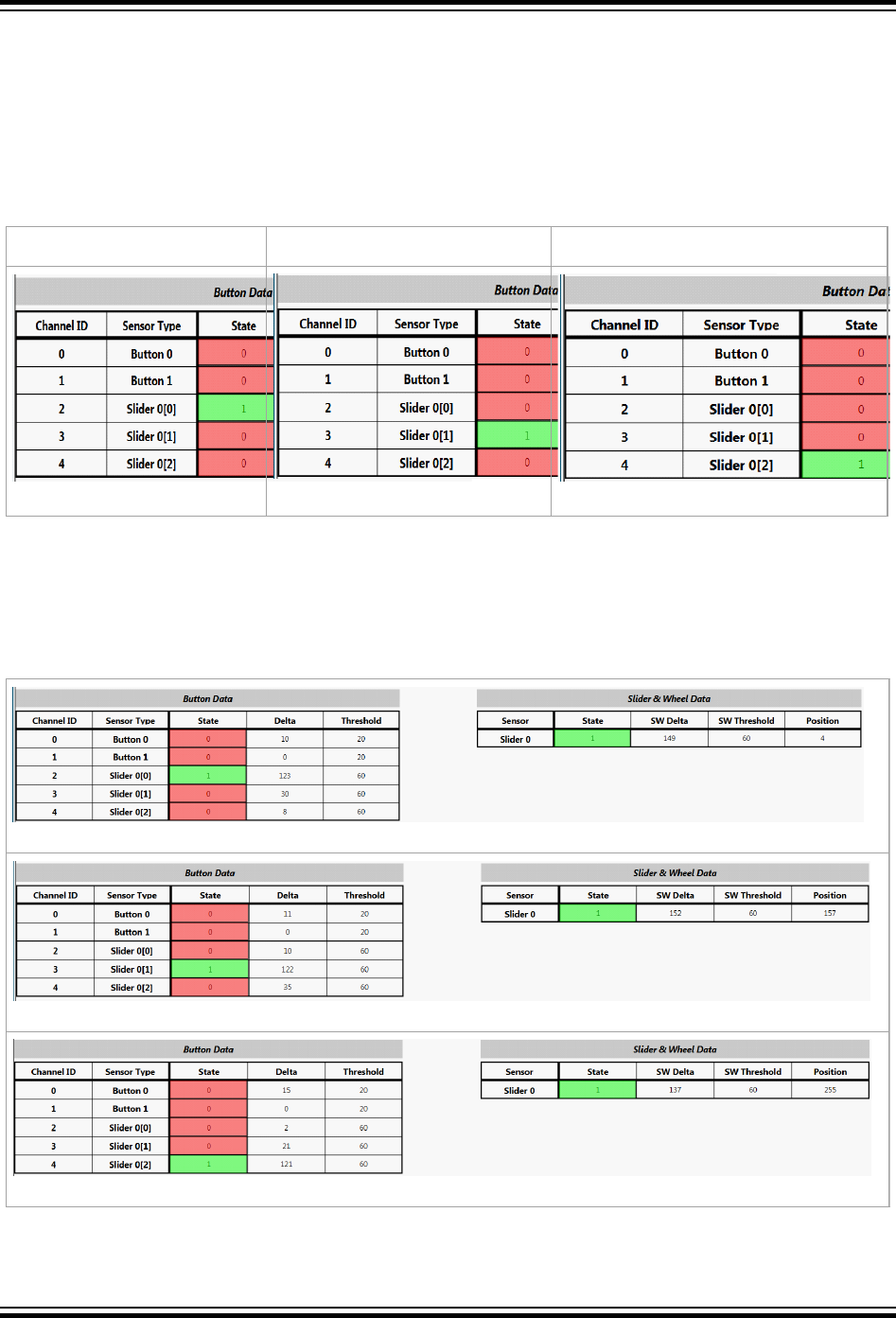

10. Scroller Module

10.1 Overview

The Scroller module processes the group of touch sensors constructed either as linear slider or circular

wheel as shown in the figure below. The slider/wheel sensors, also known as one-dimensional surface

sensors, track the touch movement scrolled over them and report the state and the position to the user

application. The size of the slider/wheel is the underlying number of the touch key sensors that form the

linear/circular surface.

Slider Sensor

Wheel Sensor

The slider/wheel can be formed by using both self cap and mutual cap sensors. The above figure shows

the 4-channel slider and 3-channel wheel sensors based on self-cap technology. To get good linearity on

the reported touch positions when the touch is scrolled over the sensor surface, the touch keys should be

inter-digitized as shown in the above figure.

GCC compiler :

libqtm_scroller_xxxxx_0x000B.a

IAR compiler (AVR MCU) :

qtm_scroller_xxxxx_0x000B.r90

IAR compiler (ARM MCU) :

qtm_scroller_xxxxx_0x000B.a

10.2 Interface

The data structure definitions and the API declarations are included in the API file

‘qtm_scroller_0x000b_api.h’. The data structure covers all the configurations and output data

variables. This file should be included on the common api touch_ptc_api.h file.

User's Guide

Scroller Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 39

User

Application

Touch.h

Macros and

constants

Qtm_scroller

_0x000b_api.

h

Touch_api_

ptc.h

Scroller

Module

common_

components_api.h

Touch.c

Global variables declaration

and initialization, Helper API

functions

10.3 Functional Description

The Scroller module processing is dependent on the Touch Key module output. After the keys are

processed and statuses are updated in the data structures, they are checked by the slider module. Based

on the key status, the slider/wheel position is calculated from the current signal values available on the

acquisition module variables.

The possible use cases and the sequence of operation under each use case are given below.

Use Case 1: Touch contact made on slider/wheel sensor

1. The module checks the status of all keys in the scroller for a touch contact detection.

2. If any key is in detect state, the touch position is calculated using the signal values of three

adjacent keys.

3. Both raw position and filtered position are calculated.

4. The scroller state comes to “TOUCH_ACTIVE” and the scroller reburst flag is set.

5. The “POSITION_CHANGE” flag is set now. The flag is cleared on the next measurement cycle if the

touch is stationary and no change in touch position.

Use Case 2: Touch contact scrolling over the slider/wheel surface

1. Module checks all keys for touch contact

2. If no key is in detect, the module searches for a pair of neighboring keys whose touch delta

exceeds the minimum contact threshold

3. If such a contact is found then the new position is calculated OR

4. If no such contact is found the scroller returns to ‘No Detect’ condition

User's Guide

Scroller Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 40

Use Case 3: Touch contact removed from slider/wheel sensor

1. The module checks the status of all keys in the scroller for a touch contact detection.

2. If no key is in detect, the module searches for a pair of neighboring keys whose touch delta

exceeds the minimum contact threshold.

3. If such a contact is found then the new position is calculated OR

4. If no such contact is found the scroller returns to ‘No Detect’ condition. That is the flag

“TOUCH_ACTIVE” is cleared.

10.4 Data Structures

10.4.1 Configurations

Table 10-1. Group Configuration

Parameter Size Range/Options Usage

*qtm_touch_key_data

Pointer 2/4

Bytes

qtm_touch_key_data_t

Pointer to touch key data for the

underlying set of touch keys

num_scrollers

1 Byte 1-to-255*

Number of scrollers

implemented in this group

Table 10-2. Individual Sensor Configuration

Parameter Size Range/Options Usage

type

1 Byte

0 = Linear Slider

Type of scroller

User's Guide

Scroller Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 41

Parameter Size Range/Options Usage

1 = Wheel

start_key

2 Bytes 0-to-65535*

Key number which forms the first

component key of the scroller

number_of_keys

1 Byte 2-to-255

Number of component keys to form the

scroller. The minimum number of keys

required to make a slider is two and the

minimum number of keys to make a wheel

is three.

resol_deadband

1 Byte

Bits 7:4 = Resolution

2 to 12 bits

Full scale position resolution reported for

the scroller

Bits 3:0 = Deadband

0% to 15% (each

side)

Size of the edge correction deadbands as

a percentage of the full scale range

position_hysteresis

1 Byte 0-to-255

The minimum travel distance to be

reported after contact or direction change

contact_min_threshold

2 Bytes 0-to-65535

The minimum contact size measurement

for persistent contact tracking. Contact

size is the sum of two neighboring keys’

touch deltas forming the touch contact

10.4.2 Status and Output Data

Table 10-3. Group Data

Parameter Size Range/Options Usage

scroller_group_status

1 Byte

Bitfield

Bit 7: Reburst required

Bit 0: Touch detection

Reburst Required = 1

Indicates that some scroller in the group

requires reburst of sensors.

Touch Detection = 1

Indicates that some scroller in the group

is in ‘Touch Detect’

Individual Key Sensor Data

Parameter Size Range/Options Usage

scroller_status

1 Byte

Bitfield

Bit 7: Reburst

required

Bit 1: Contact moved

Bit 0: Touch

detection

Reburst Required = 1

Indicates that some scroller in the group requires

reburst of sensors.

Touch contact reported position has changed

Touch Detection = 1

User's Guide

Scroller Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 42

Parameter Size Range/Options Usage

Indicates that some scroller in the group is in

‘Touch Detect’

right_hyst

1 Byte Hysteresis limit

Indicates when a contact is moving ‘Right’, ie.,

The direction of increasing touch position

left_hyst

1 Byte Hysteresis limit

Indicates when a contact is moving ‘Left’, ie., The

direction of reducing touch position

raw_position

2 Bytes 0-to-4095

The calculated location of the touch contact prior

to motion filtering

position

2 Bytes 0-to-4095 The calculated location of the touch contact after

motion filtering

contact_size

2 Bytes 0-to-65535 The sum of two neighbouring keys’ touch deltas

comprising the touch contact

User's Guide

Scroller Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 43

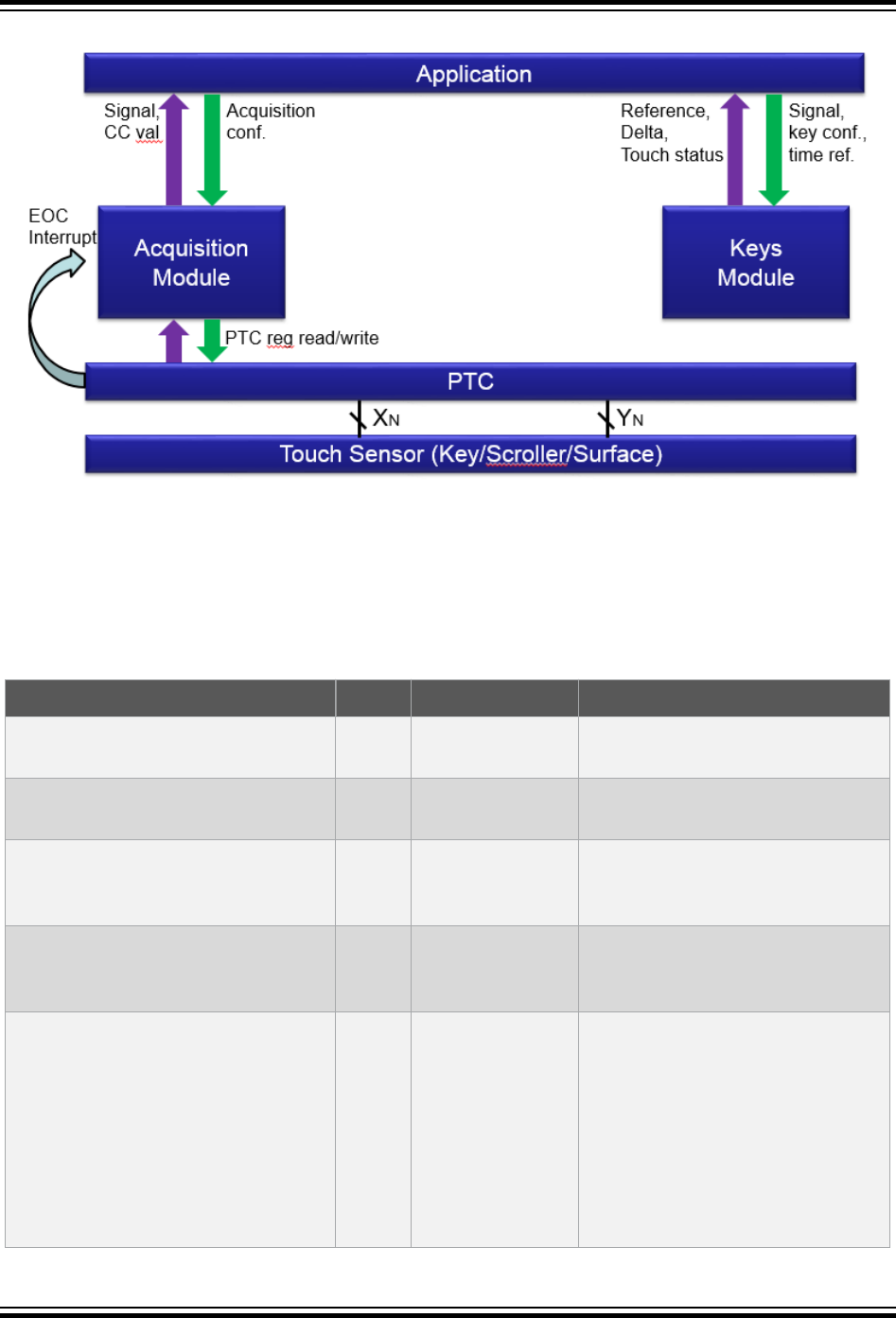

11. Binding Layer Module

11.1 Overview

The binding layer is the generic framework that binds the QTouch Library modules and automates the

initialization and processing of modules. The binding layer is configured with data pointers and function

pointers of the QTouch modules which are used to execute the module API functions in the appropriate

sequence. The binding module also provides callback on completion of every stage to the user

application.

The binding includes the acquisition module, signal conditioning modules and post processing modules.

Controlling all the modules with unified application interface reduces the complexity of handling multiple

modules, their states and errors and callback functions. The user application code can also be built as

library module and automated using the binding layer provided the user module conforms to the QTouch

modular library architecture.

Figure 11-1. Binding Layer Framework Block Diagram

BINDING LAYER

MODULE

CONFIGURATION

(Data pointers,

Function pointers)

Acquisition

Module

Post

processing

Modules

(keys,

frequency

hop, scroller)

Initialization Complete callback

Measurement Complete callback

Post Process Complete callback

Error callback

Table 11-1. Module Format

GCC compiler :

libqtm_binding_layer_xxxxx_0x0005.a

IAR compiler (AVR MCU) :

qtm_binding_layer_xxxxx_0x0005.r90

IAR compiler (ARM MCU) :

qtm_binding_layer_xxxxx_0x0002.a

11.2 Interface

The data structure definitions and the API declarations are included in the API file

‘qtm_binding_layer_0x0005_api.h’. The data structure covers all the configurations and output

data variables. This file should be included on the common api touch_ptc_api.h file.

User's Guide

Binding Layer Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 44

User

Application

Touch.h

Macros and

constants

Qtm_binding

_layer_0x000

5_api.h

Touch_api

_ptc.h

Binding

Layer

Module

common_

components_api.h

Touch.c

Global variables declaration

and initialization, Helper API

functions

11.3 Functional Description

Binding layer automates the following processes of each module.

1. Module initialization

2. Capture success/error and report through callback

3. Module post processing

4. Capture success/error and report through callback

5. Capture “module reburst” flag and retriggers the acquisition based on the ‘Reburst’ status

User's Guide

Binding Layer Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 45

Figure 11-2. Binding Layer-based QTouch

®

Application

Error handling support by binding layer module:

The individual module errors are validated inside the binding layer and they are encoded and passed to

the application as single error code.

The error code is decoded in the touch.c file and displayed on the data visualizer software. The error

code format is given below.

Acquisition Module Error codes: 0x8<error code>

0x81 - Qtm init

0x82 - start acq

0x83 - cal sensors

0x84 - cal hardware

Post processing Modules error codes: 0x4<process_id>

0x40, 0x41, 0x42, ...

process_id is the sequence of process IDs listed in #define LIB_MODULES_PROC_LIST macro.

Process IDs start from zero and maximum is 15

Examples:

0x40 -> error in post processing module 1

0x42 -> error in post processing module 3

Decoded Module_error_codes:

Acquisition module error = 1

post processing module1 error = 2

post processing module2 error = 3

... and so on

User's Guide

Binding Layer Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 46

11.4 Data Structures

11.4.1 Configurations

The container structure that holds the entire configuration of binding layer is given below.

typedef struct qtm_control_tag

{

uint8_t binding_layer_flags;

module_init_t *library_modules_init;

module_proc_t *library_modules_proc;

module_acq_t *library_modules_acq;

module_arg_t *library_module_init_data_model;

module_arg_t *library_module_proc_data_model;

module_arg_t *library_modules_acq_dm;

qtm_acq_pp_t *qtm_acq_pp;

/*******************************/

/* Callbacks for Binding layer */

/*******************************/

qtm_library_init_complete_t qtm_init_complete_callback;

qtm_error_callback_t qtm_error_callback;

qtm_measure_complete_t qtm_measure_complete_callback;

qtm_pre_process_callback_t qtm_pre_process_callback;

qtm_post_process_callback_t qtm_post_process_callback;

} qtm_control_t;

Parameter Description

*library_modules_init

Pointer to the array that contains the list of module

initialization function pointers.

*library_modules_proc

Pointer to the array that contains the list of module post

processing function pointers.

*library_modules_acq

Pointer to the array that contains the list of acquisition

module function pointers.

*library_module_init_data_model

Pointer to the array which contains the Data Pointers of the

acquisition modules.

*library_module_proc_data_model

Pointer to the array which contains the Data Pointers of the

post processing modules.

*library_modules_acq_dm

Pointer to the array which contains the pointers of

acquisition groups.

qtm_init_complete_callback

Callback provided by binding layer module after executing

all the module initializations.

qtm_error_callback

Callback function triggered only if there is any error

encountered by the binding layer during the module

processes.

qtm_measure_complete_callback

Callback triggered by binding layer module after the

completion of measurement and before post processing.

User's Guide

Binding Layer Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 47

Parameter Description

qtm_pre_process_callback

Callback triggered after the acquisition process and before

post processing. This is provided to enable user to

implement custom filtering modules.

qtm_post_process_callback

Callback triggered by binding layer module after the

completion of all the post processing of modules.

11.4.2 Status and Output Data

Parameter Description

binding_layer_flags

Three status flags are set inside the binding layer callback functions to

perform further processing the Application.

Three binding layer flags are supported in the current version as below.

time_to_measure_touch:

This flag is set on the timer ISR handler and when any module reburst is

requested. This flag is used to trigger the measurement on either one of the

above conditions met.

node_pp_request:

This flag is set in the measurement complete callback to indicate post

processing is required. This flag is handled in the touch_process function.

reburst_request:

This flag is set in the post process complete callback and this is set based

on the individual module reburst flags. This flag is handled on the

touch_process function.

User's Guide

Binding Layer Module

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 48

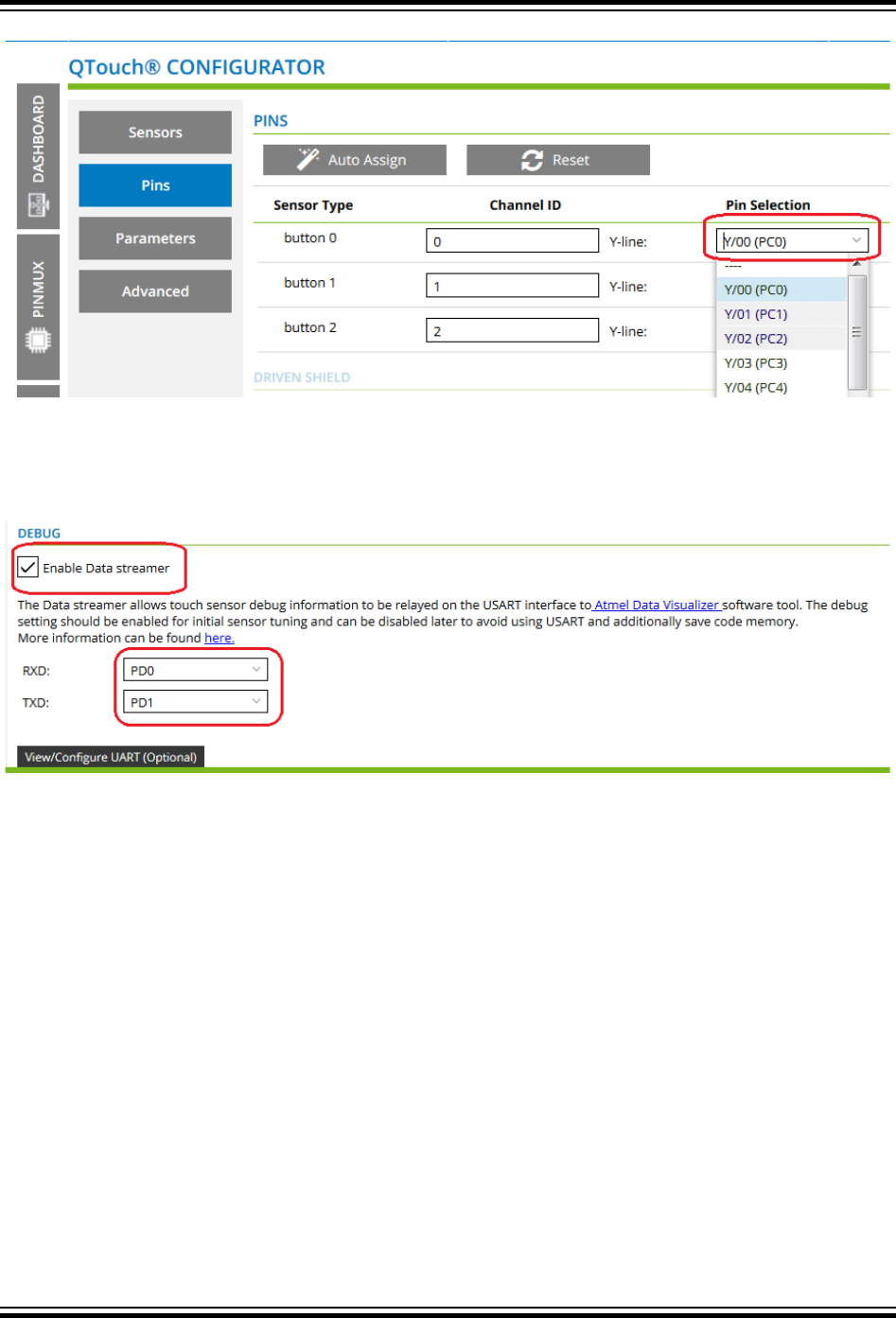

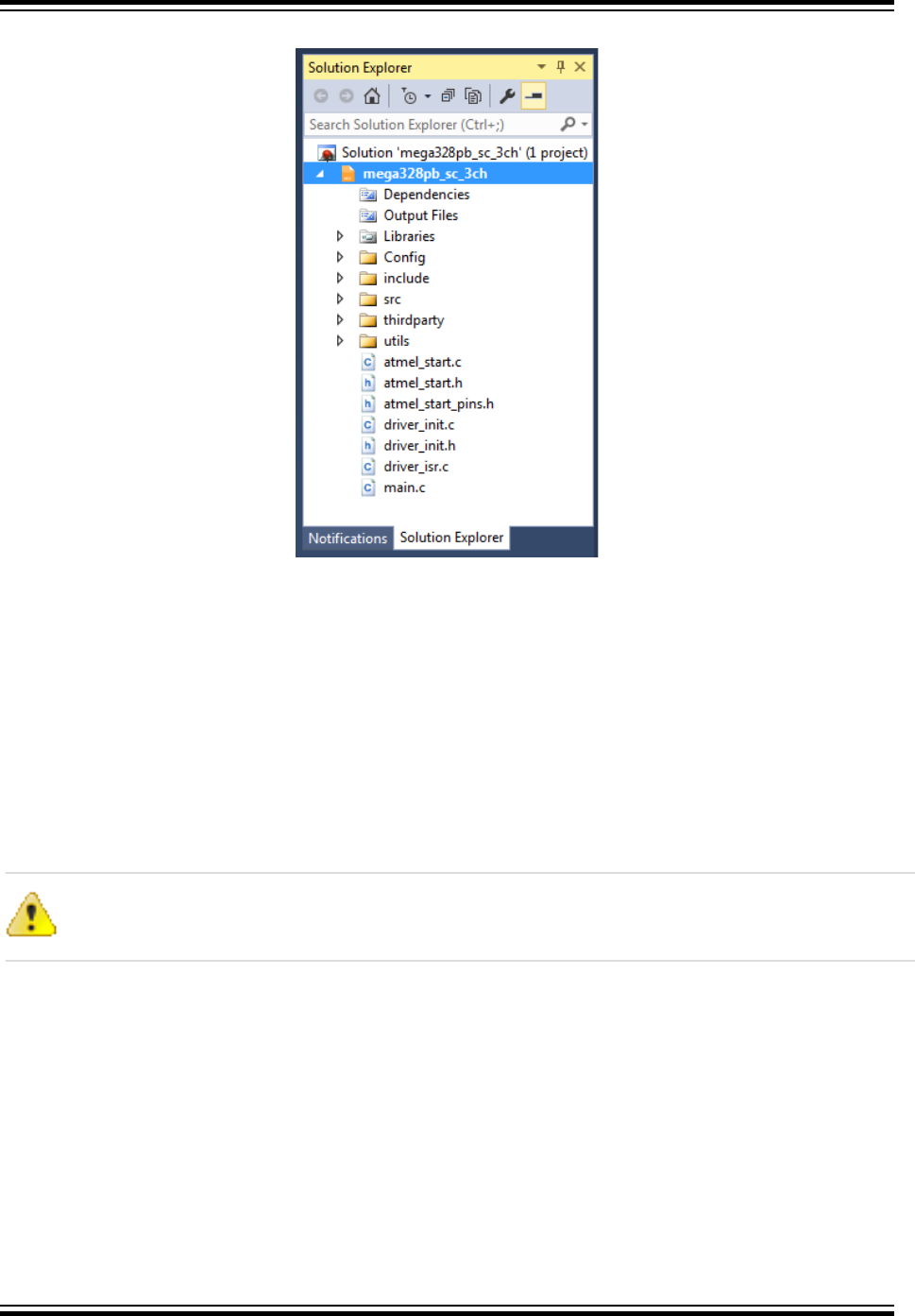

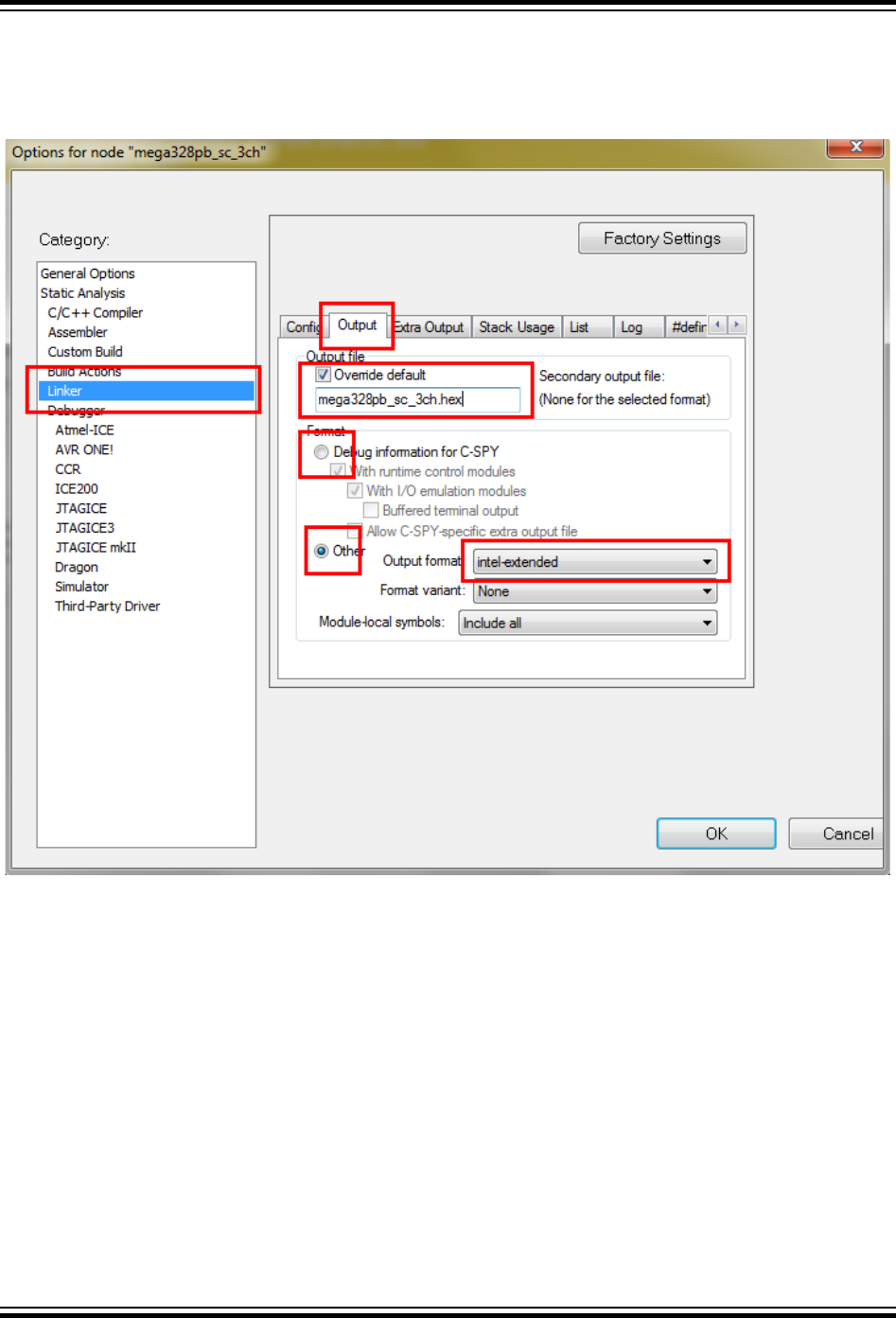

12. Building Applications Using Atmel START

Atmel START helps the user to select and configure software components for Microchip MCUs. The

QTouch project can be created using Atmel START. The user can add sensors and configure QTouch

parameters represented in graphical ways. The created project supports GCC and IAR compilers.

12.1 Working With KIT Example Projects

Atmel START provides example projects for standard Xplained Pro and Xplained Mini kits. The kit

examples are a good way to get up and running with touch applications. The projects can be downloaded

and built with the following steps.

Step 1:

Open Atmel START main page and click ‘Browse Examples’

Step 2:

Select one of the listed KIT example projects by clicking on the description. Click the ‘Download selected

example’ button and save the atzip file.

User's Guide

Building Applications Using Atmel START

© 2017 Microchip Technology Inc.

User Guide

DS40001986A-page 49

Step 3:

Import the atzip file into Atmel studio or IAR IDE and build the example. Flash the built binary on the

target MCU.

Step 4:

Open the data visualizer software and configure the path to the directory

“<example_project_directory>\qtouch\datastreamer\”.

Step 5:

Connect the data visualizer to the target hardware using a serial port channel and verify the ON button

touch status. The on-board LED will turn on when touch is made and vice-versa.